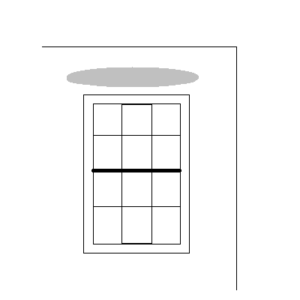

Not a rocker, and didn’t stay at a Holiday Inn last night, so I could use some advice on how to replace a section of rock in a way that will show the least and last. It’s only one and it’s for me so extra time is ok. The window has a corner about a foot to the right of it. The gray oval is the part that has to be replaced. It’s slightly wider than the window framing on the right, and maybe 8″ wider on the left.

So where to cut? Seems like the bottom so most falls under the window casing is a no-brainer but what about the rest? Put a rectangle around it, go all the way to the ceiling and wall (two inside corners, but two less butts, etc.

Replies

Find the studs. Where are they in this picture?

Location of studs (ignore the short one at the top, drawing error).

Unless the studs happen to land where you can easily use them (and it appears that they don't), ignore them and patch where you need. Here's what I would do:

Cut out the damaged portion a little smaller than it needs to be. Feel around behind to drywall to determine how much more needs to be removed. Now is also a good time to decide if you can use a stud, but it's usually not worth the trouble to cut the drywall so it half-laps the stud.

Once you know how big the patch needs to be, cut a basically rectangular patch. Trace it onto the wall so the patch will be a perfect fit. Do not make it a snug fit, 1/8" all around is good.

Use backers (1X2 pine works good) to span the hole and secure it by screwing through the drywall. If you removed all of the damage, you will have no problem securing it this way. Behind the header, if there is one, you might need shims if the header wasn't packed out. The new piece gets secured to the backers and the shims. Doing is this way assures that the new piece of drywall is "in plane".

Use a utility knife to trim the edges of the old and new drywall making a small notch or "V". Fill this notch and the 1/8" gap with a setting compound. Durabond would be best, but EasySand also works. You can even use a water putty like Durhams.

Once the setting compound is dry (not just set, but also dry), make sure that old and new are in plane and prime the patch and wait for the primer to dry.

Now, find some drywall crack repair tape. There's some self-adhesive stuff out there, but the stuff I use has an adhesive that needs to be wet first. I've never found it online. I pick it up at my local paint store so you may have to hunt around for it. It's very thin since it doesn't require compound underneath it. It's not as strong a regular paper tape, but it doesn't need to be for this kind of repair. Also, there's no need to overlap the tape at the corners

Finally spackle over the tape. 2 light coats should be plenty.

Pete, what you patch you need to paint.

So, I would stay short of the ceiling so I wouldn't have to tape the corner. Depending on the size and real shape I might just cut out the bogus part-fit the non sq. patch and either let the paper of the wallbd be my tape or use paper tape.

edit. I might use wood scraps as backer and something to screw to along with the header/studs if present.

You just want the patch to register properly with the existing wallbd.

A Great Place for Information, Comraderie, and a Sucker Punch.

Remodeling Contractor just outside the Glass City.

http://www.quittintime.com/

Edited 11/4/2009 5:42 pm ET by calvin

I'd cut the old rock far enough to get rid of the damage, without worrying too much about where the studs are, and from the top of the window to the ceiling. Then use some scraps of pine or ply as backer for the joint between old and new rock.

If you don't want to have to repaint the ceiling, you could cut the rock 2-3" down from the ceiling, and have another flat joint to tape.

Then patch in new rock, tape and mud it with EZSand 45 so I can recoat quickly, topcoat and feather out the repair with same (as needed, 2-3 coats), and let someone else paint.

What happened to require the repair?

That should all be header. If the house isn't new, and has done it's settling, you can cut your patch piece (big enough to cover any crumbly edges), hold it over the hole, scribe it, then do your wall cutting.http://www.tvwsolar.com

We'll have a kid

Or maybe we'll rent one

He's got to be straight

We don't want a bent one

He'll drink his baby brew

From a big brass cup

Someday he may be president

If things loosen up

Yes, cut the patch first and then cut the the wall to match the patch.

I have cut many a hole in preparation for a repair and taking the extra trouble to make sure it's a perfect rectangle, measuring the hole and then cutting the patch to that size. One day it dawned on me that I was doing it backwards.

It's so much easier to cut the patch first.

I spend way more time fixin' than I do doin'<G>http://www.tvwsolar.com

We'll have a kid

Or maybe we'll rent one

He's got to be straight

We don't want a bent one

He'll drink his baby brew

From a big brass cup

Someday he may be president

If things loosen up

Any suggestions on keeping the wall looking flat with all those short butt joints?

To keep the patch looking flat, feather out the taping job well past the patch.A Great Place for Information, Comraderie, and a Sucker Punch.

Remodeling Contractor just outside the Glass City.

http://www.quittintime.com/

FWIW, there are special screws available which have fewer but wider threads. They are used to fasten one layer of drywall to another. In this case they would serve to hold a drywall bridge to the back of the patch piece. I'm not sure what their official name is now. When I was doing commercial drywall we called them "rock to rock" screws.

i learned drywall from my friend's father- he subbed out the rocking, but did all the taping with his brother.on all of the butts, he would peel the paper from both sides of the joint. i kid you not. this creates a space for the tape to sit in- replacing the thickness of the paper on the drywall with the thickness of the tape.i don't do this on butt joints, but i do do it on patches.also, make sure you put the paper tape with the right face down. that line down the center of the tape (for folding it) forms a ridge on one side of the tape, and an indentation on the other. always bed the ridge into the mud.

Good tips. I have on occassion peeled the paper back like you said to make a flatter butt joint. When I do that, I like to use a primer on the exposed gypsum to help adhere everything together before taping and mudding.

"cut the patch first"

I've fixed a lot of holes and hadn't ever thought of this - thank you.

(can't believe how sheetrock holds such a world of obvious, simple solutions)

Backing up a bit, are you SURE that the GWB needs to be replaced? That's an odd place for a doorknob or a fist to go through the wall...

Cracks in that location are common, although not so much with the kind of framing you show -- are you sure that there is no header?

Header shrinkage/settling is the most common cause of cracking there. But replacing the GWB is rarely necessary.

Usually it's just a mud job. Setting compound is stronger than drying compound, use that.

But how about a photo so that we can do a reality check?

And Hudson Valley Carpenter is talking about laminating screws, which are handy to have around.

AitchKay