A Solid, Well-Insulated Foundation

Insulated concrete forms (ICFs) provide integral foam insulation at the base of a house.

Every house should be built on a solid foundation and the FHB House is no exception. In fact, like other elements of the project, we wanted the foundation to demonstrate best practices and to work as part of a system for this performance-oriented house.

ICF’s fit the bill

The sloping site suggested that we would have a walk-out basement, which in my experience usually means poured concrete walls on footings stepped to stay below the frost line, with rigid insulation on either the interior or exterior of the walls to meet or exceed code requirements in cold climate zones. Usually the concrete is kept relatively close to grade, with the remainder of the walls built with framed walls.

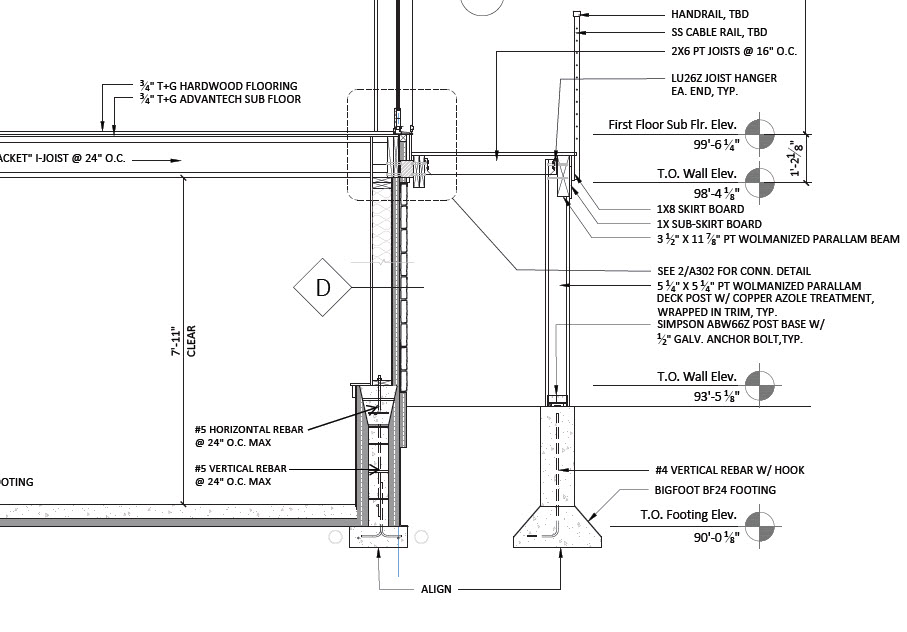

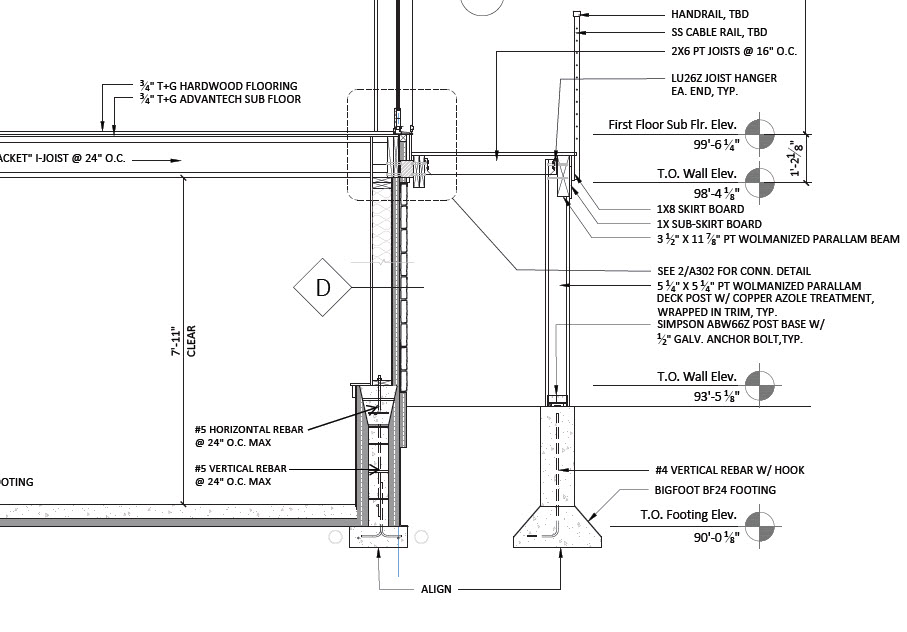

Start on solid footing

Start on solid footing

A good foundation has to sit on good substrate. According to the IRC 2012, which is the basis for Rhode Island’s building code:

“Footings shall be supported on undisturbed natural soils or engineered fill.”

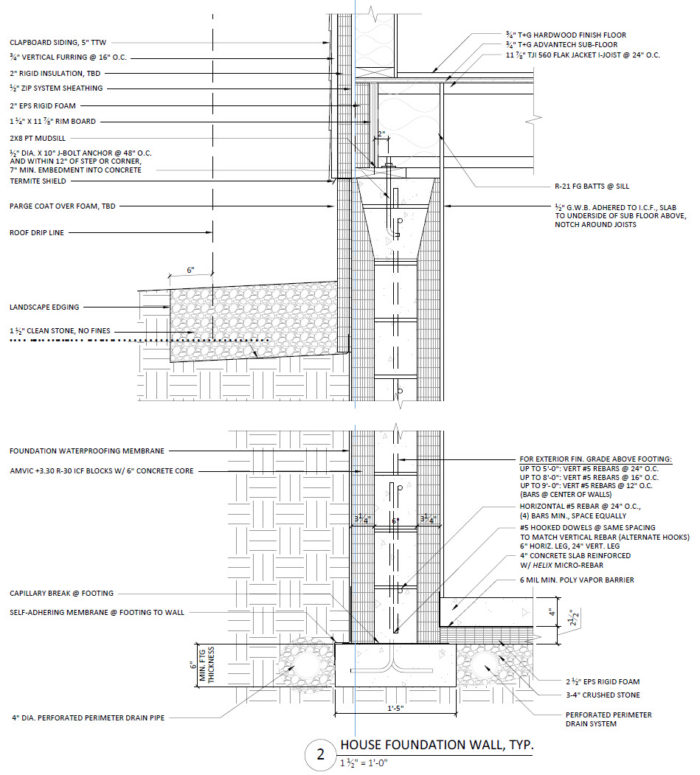

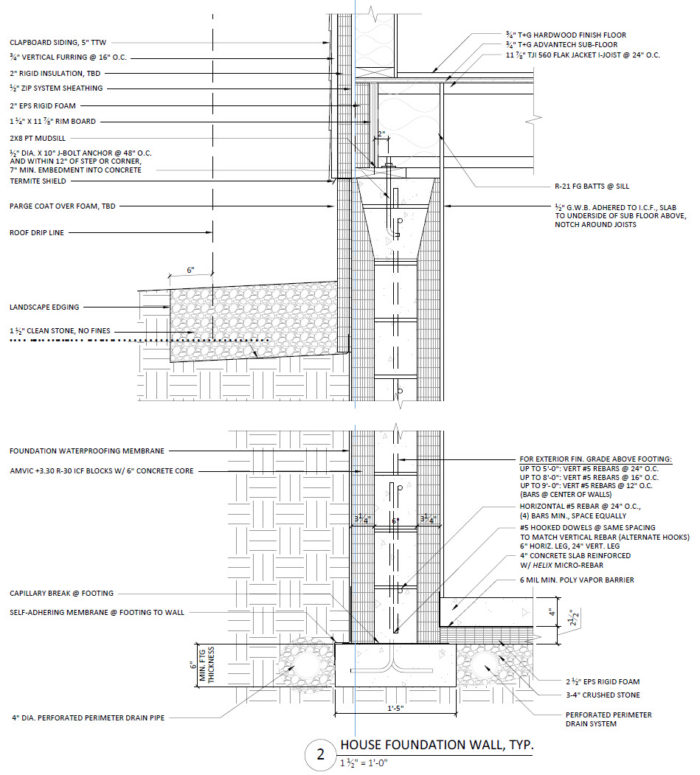

On top of the substrate is the footing, which can be a range of different sizes depending on the situation. The primary reason for the footing is to spread out the static and dynamic loads on the building, but the footing also creates a flat, level surface on which to place wall forms, and when tied to the wall with steel rebar, footings can also resist upward loads, as might be imposed on tall, narrow buildings when strong winds or seismic loads try to push them over. Footing size depends on the building loads and the soil bearing capacity, and are often built larger than loads and code require.

Footings are often shown and sometimes built with keyways, which are trenches cast into the footing to “key in” the walls once they are poured. They are intended to prevent lateral movement, but even with soil pushing on the exterior, a slab floor poured on the inside, and with rebar spanning the cold joint (where concrete is poured against already-cured concrete), there is typically little need for a keyway.

There is a need for a capillary break, one of those details that some builders are still lagging on incorporating because the advantages can be hard to observe. In a tight house,when the porous concrete is allowed to wick water from the soil, moisture-related problems occur that could have been easily avoided by adding a capillary break. There are several products designed to be a capillary break between the footing and the wall above, to reduce or eliminate moisture movement from the ground up into the wall. Footings sometimes include rebar, but often don’t, for the simple reason that the wall above functions as a giant beam (especially if it includes horizontal rebar) so the extra reinforcing that rebar in the footing provides is just not needed.

A Hybrid Approach to Footings

A Hybrid Approach to Footings

One unique approach on the FHB House is at the walk-out portion of the basement, where due to a high water table, it would be difficult to reach the code-required 40” minimum from grade to the bottom of the footing. Mike Guertin suggested we use frost protected shallow foundation details at that location. Both Mike and I have experience building frost protected shallow foundations, which incorporate rigid foam to capture the earth’s heat and protect cold air from freezing the ground below a foundation built above the frost line. There were two problems with that approach, though: Rhode Island’s building code limits the height of buildings on frost protected shallow foundations to one story in height, and it includes limitations on combining frost protected shallow foundations with other foundation systems. Fortunately, Mike Guertin is on good terms with his local code enforcement officer, who has discretion to overrule the code when appropriate. After talking with our engineer, David Macolini of Becker Structural Engineers, and with Mike Guertin, the code official allowed our hybrid system. According to Mike, in July, Rhode Island will release an updated code that will prescriptively allow a foundation like ours.

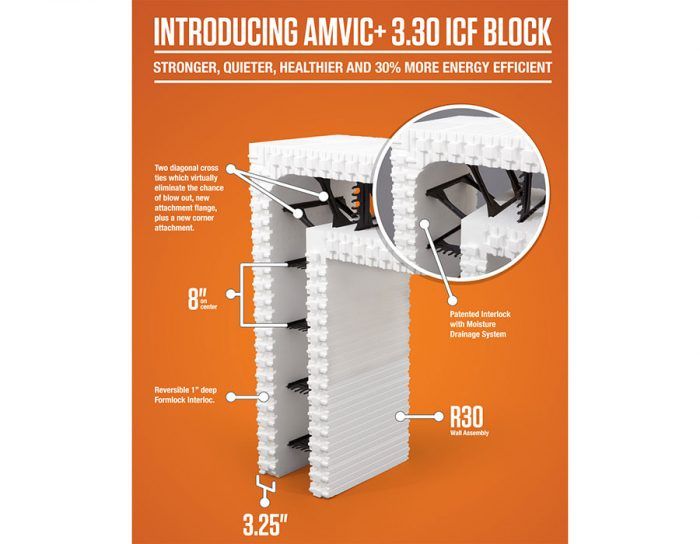

ICF’s: self-contained forms

The Amvic brand blocks we chose have the highest insulating value in the industry. Each side of the form has 3 ¼” of foam at R-13.67 per side; once the other components of a typical wall are added, the whole wall is rated at R-30, which exceeds code and is about the same as our framed walls above. (Code requires R-15 continuous insulation (or R-19 cavity insulation) for basement walls, and R-20 for framed walls in Rhode Island’s climate zone, 5.) The blocks are made from EPS (expanded polystyrene), which has the most environmentally friendly blowing agent of any rigid foam and an R-value that remains constant over time.

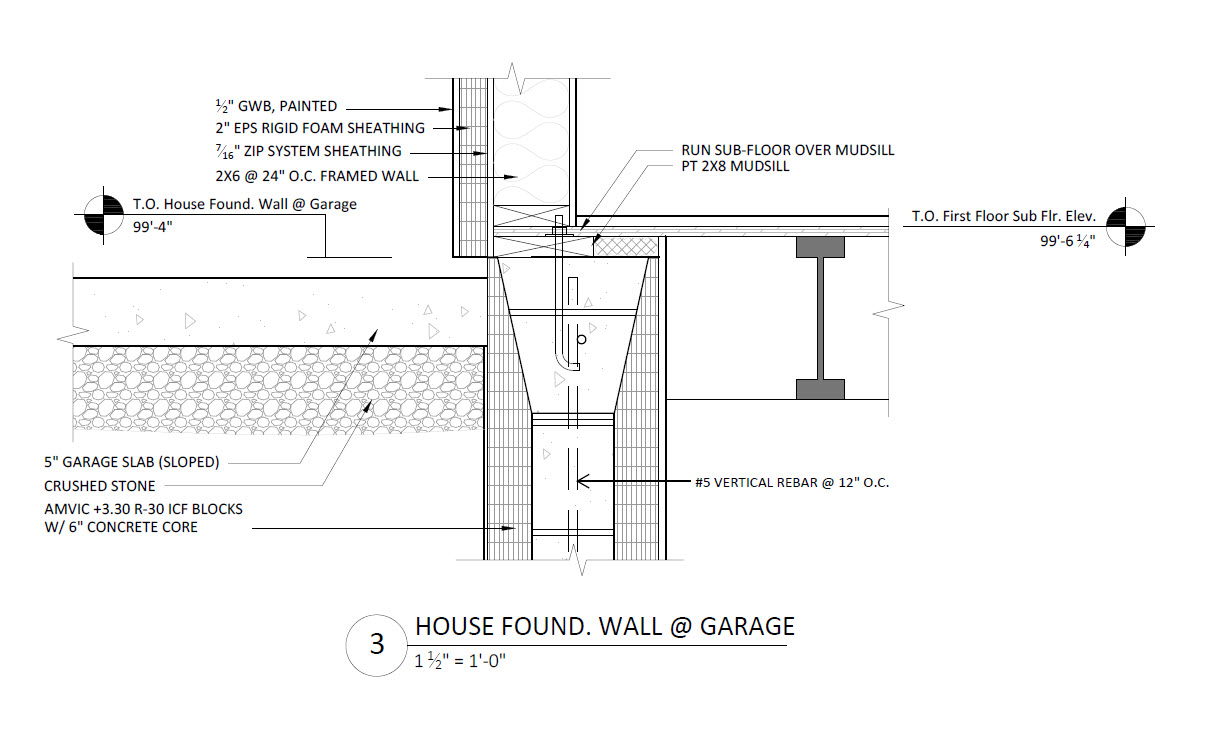

Our intention was to use framed walls instead of ICF’s for the above-grade portions of the basement walls, which would make it easier to frame out the window and door openings, and minimize the use of energy-intensive concrete and foam. However, our structural engineer calculated that we needed to make most of the foundation full-height ICF’s in order to resist soil pressure from the uphill side. We argued about this detail, as many foundations have part-height concrete walls, but in the end the engineer would only approve the drawings with a small portion of the south wall framed. Hydrostatic pressure in the soil exerts a tremendous amount of pressure, and with a two-story structure in a 110 mph wind zone on top of the foundation, the engineer was not comfortable skimping on what amounts to bracing the foundation walls. He also spec’d a fairly rigorous rebar schedule, which provides a tension element that works with concrete’s compressive strength to create a robust foundation wall.

Although we don’t need the insulating aspect of the Amvic forms for the entry porch and garage foundation, it made sense to use the same system so Mike and his crew could do the work at the same time, without having to bring in subcontractors.

Waterproofing and Finishing Touches

In future posts I’ll write about how we’re treating the exterior of the foundation and dealing with stormwater and groundwater management.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Anchor Bolt Marker

Original Speed Square

Smart String Line

View Comments

The use of ICFs is greatly overrated. Half of the insulation is on the outside of a very heavy wall. When the homeowner returns home (and raises the thermostat) it takes hours and hours to heat the ICF enclosed space (basement) because the concrete is being brought up to temperature also.

From an energy efficiency standpoint, why would a homeowner want to heat a massive volume of concrete?

This can be overcome by adding further insulation to the inside of the basement walls, but that is not how the ICFs are being used.

They are best used in a temperate climate, where one can use the thermal mass to one's benefit. Unfortunately, I've seen them used in the "near north" of Canada, on seasonal residences no less. --arrive Friday evening and it's finally warm by Saturday evening.

Suburbanguy, if you are relying on thermal mass to moderate temperature swings within your home, it would be smart, from an energy use point of view, to insulate the exterior of the foundation only.

However, in a house with very low levels of air leakage (we are aiming for 1.0-1.5 ACH50) and a decent amount of insulation (we have R-30 walls and an R-60 roof in zone 5), thermal mass and thermostat setbacks don't have the same effect as they would on a poorly insulated, drafty house. With a good building envelope and efficient equipment, as we will have, the house will be able to "coast" over many hours without needing thermal mass to make up for heat losses. Concrete is a very good conductor of heat (aka a very poor insulator) so the effects of thermal mass are not as great as most people think; exposed concrete walls as you suggest would likely reach equilibrium with the indoor air after 6-10 hours, after which time you would have to somehow charge them with heat again, which is easy if they get direct sunlight, but most foundation walls don't get direct sunlight, so they need conditioned air (heated another way) to function as a thermal flywheel. In fact, the ProHOME basement will probably be finished off at some point, which would even make it difficult for conditioned air to heat the concrete.

The concrete is protected between layers of insulating foam, so essentially it neither contributes or detracts from the thermal performance of the house. We are also able to keep the concrete to only 6" thick; with a poured foundation we would need at least 8" walls. Manufacturing concrete is very energy intensive (they burn limestone to get the portland cement) so the less we can use, the better.

In my opinion, thermal mass is best used in very hot climates with cool nights, such as New Mexico, where it can help moderate diurnal temperature swings. In most climates, though, it makes more sense to build an envelope with enough insulation, low rates of air leakage, and well-designed windows to get some (but not too much) passive solar heat.

Great foundation details! Any chance I can ask what you are planning to use for a capillary break between the footing and ICFs? I am getting ready to break ground on a ZNE home this month and have been scrutinizing this detail for quite some time. In the past, I have used a cementacious product from Thoroseal. It was basically a ready mix product from a bag that is trowelled over the footing prior to wall form placement. It seems like a decent product but the fact that it is also cement based and supposed to block the transport of moisture seems counterintuitive. But hey, who am I to question what the guys in the lab come up with?

Also, how are you planning to alter the top course of ICFs to allow for the thicker concrete. Carve the EPS out between the plastic webs? Will you be adding additional shuttering and bracing to avoid blow-outs when it comes time to pump the concrete into the ICFs? The engineer for my ZNE project had similar details for the ICF foundation. I am trying to get them to provide alternate details for this, finger's crossed. It seems like a lot of extra work, and I understand why they want it for load transfer buuuut... It is also a detail I cannot find on any of the manufacturers website's of ICFs.

I look forward to more articles and updates on the ProHome! I commend FHB and the pros doing the work for having the guts to go for such an ambitious undertaking.

Detail_Devil, thanks for the comments. I have used Thoroseal products before but not for a capillary break. The main ingredients for the Thoroseal products I'm familiar with are silica and Portland cement, with some other minerals and sometimes polymers added. It's pretty effective at keeping out water but I'm not sure if it's as good at preventing capillary movement of water, which is drawn from larger pores to smaller pores.\P\P

We will be using a Cosella-Dorken product, Delta Footing Barrier: http://www.cosella-dorken.com/bvf-ca-en/products/foundation_residential/footing_barriers/products/footing_barrier.php. Basically a sheet of polyethylene with special coatings on both faces, it is troweled onto the freshly poured footing. I know that many people like liquid-applied membranes and control layers of various sorts, but personally I find it easier to work with sheet goods and tapes when possible. \P\P

The Amvic brand ICF's we are using offer "Taper-Top" forms for the tops of the walls, as well as other shapes for various situations. You can see their CAD details here: http://www.amvicsystem.com/icf/cad/. I have not used ICF's myself and can't comment on how Mike Guertin will handle bracing the forms during the pour, but he has experience with ICF's and I'm sure he will blog about pouring the walls.

Mike,

Foam on the outside of a concrete wall is almost useless in a cold climate unless one wants to waste money heating concrete. The ICF's might typically have 2 inches of foam--just R10 on the inside and contractors simply drywall over this based on the erroneous marketing data of R20 (which includes the exterior foam).

If the exterior is -20C, the concrete would be a pretty uniform 0C (on a partially exposed basement wall) and the inside of the basement would be +20C. Why would anyone want to heat the massive concrete up to 0C?

Our minimum building code is R12 for basement walls--completely unsatisfactory when used as finished space, but still more than ICFs.

Yes, in climates with warm days and cool nights or ones that are simply temperate, ICF's are great, but elsewhere they need extra insulation on the inside.

I don't care how few air changes the home will have. It will not affect the fact that one will have to heat massive concrete by 20C.

To install ICF's on recreational property that one only visits on weekends is further insanity. (It's finally warm just a few hours before you leave.)

I was a professional engineer and engineering professor before retiring. I know what I'm talking about. Don't drink the marketing cool aid.

Suburbanguy, you are not heating up the concrete to 20°C, you are maintaining an interior air temperature of 20°C with R-13.7 (h•ft²•°F/Btu) of insulation against heat loss to a surface (concrete) significantly warmer than the outdoor air. Concrete’s higher conductivity compared to air partially negates the effect, but the point is still valid, and part of the reason that low levels of air leakage do matter.

I agree, it would be great to add even more insulation to the interior, and if we had used more conventional ICF’s (or a poured concrete wall) that is just what we would have done. You may find it interesting that most engineers I talk to insist that insulating the exterior of the walls is always preferable in a cold climate, though I disagree. You may enjoy reading this report from the Building Science Corporation: http://buildingscience.com/sites/default/files/migrate/pdf/BA-1003_BA_HighR_Foundations_Report.pdf.

Suburbanguy - I built a 2200 sf one-level ICF house and have lived in it for 3 years now (Central PA). I think - from my experience - that ICFs should be used much more. They offer superior strength, stability and insulation. Not only in terms of R-value, which is not exceptionally high, but combined with the super-tightness of poured walls they really have an exceptional heat retaining ability. I heat my house by running a Tarm Solo Innova wood boiler for about 3-4 hours every afternoon during the winter (on average). Many days I just don't run the boiler - not needed because the temp stays comfortable. I built a 1000 gal heat storage system that I have never used because the house works as a giant heat sink. The temperature is very stable inside in spite of very low temps and large swings in temps. Don't need AC either - in the summer it is sometime 15-20 degrees warmer outside than inside. I have taken care to place the house well with the façade with bigger windows facing south and the back of the house partly buried in a hill (about 3'). This is a great system! Considering all the damage from hurricanes and floods in certain areas in this country I think ICFs should be used much more.

Mike and Henrik,

Mike,

I did not say the concrete was heated TO 20C. I said it was heated (up) BY 20C. You have not answered my question of why would anyone spend money to heat up the concrete by 20C (in my -20C/0C/+20C question) You have agreed with me regarding extra insulation. R13.7 is just above the minimum building code here in Canada--and only the lowest quality homes are built to that standard. Building Science Corp is an American co. In general your climate is much different than in Canada.

Just as in any profession there are practitioners who are pretty incompetent, so it doesn't surprise me (and maybe you) that the one's you've spoken to think insulation should be on the outside. Please also read my response to Henrik.

Henrik,

Central Penn is not near north Canada. Trucks are taken out onto the lakes to deliver building materials, etc. Do you understand how cold it is when lakes develop a couple of feet of ice? Totally different climate and heating your vacation home from a starting temp of 45F (or maybe completely unheated) each weekend is not the same as setting the temp back a few degrees when you leave for work or go to bed. For your climate and your situation, go ahead use ICF. (You're still heating concrete somewhat unnecessarily, but it's your money.)

Please everyone, read what I wrote.

My buddy used ICFs on his new build vacation home with disastrous results which is why I'm so maniacal in getting the word out about the problems with ICFs. Use them, but know the drawbacks.

The fact is, every situation is unique, with different factors driving decisions. A house in Canada heated only on the weekends is clearly not the same as a fully occupied house in central PA. I have designed and/or built code-minimum houses, Passive Houses with R-58 walls and R-140 roofs, and everything in between. Thermal mass has an effect but it can be hard to quantify as it depends on many variables. Running a wood boiler for 3-4 hours every day does not sound particularly efficient from a Passive House point of view, but we would need to know the Btu output to make a informed judgement. For the ProHOME situation, including climate, house design, site conditions and other construction realities, the Amvic 3.30 blocks were a good choice.

good design

Well, the comments make for interesting reading; different opinions breed good ideas. I had a house 40 years ago with a walk out basement and no basement insulation - bad idea. I amended the attic to 16" of batts. The second house was much the same. In both instances I ran a dehumidifier 24/7 in spring, summer and fall.

This is my fourth house. Whoever built it was OCD when it came to moisture control. The outside of the foundation was coated hot tar and covered with some kind of mesh material which was then covered with a thick layer of something and then covered by 4" of rigid foam. When I bought the house I could smell the raw concrete in the basement and it was dusty. Two coats of Ulra Drylok on the walls followed by two coats of SW highly reflective paint and two coats of SW concrete enamel on the floor. Third winter - the foundation was poured concrete with a brick pattern so I did nothing. It is warm year round and never damp or dusty so the wool area rugs on the floor are just fine. As to heating (I have post polio syndrome so I have to keep it warm) I do not know the real cost. But the total cost for heat, hot water, cooking and laundry rarely reaches $60/month in zone 5/6. Next year I will add 8" of batts over the blown in insulation. I hate that stuff - looks good when it is first done and then it settles.

I want to build a house and will likely over build the footings and walls, damp proof both sides and stud out the inside to take 6" or 8" of Roxsul. I am not confident that ICF foundations will stand the test of time while mineral wool has been around for at least 70 years. For footer drains, I want them to run to daylight, though in Ohio sumps are code. That was very useful in my last house when the basement was flooded - 1,800 sf. to 2' in 17 minutes! A small trash pump and my sump pump and I was "dry" in 7 hours. The drains ran for another two days or so.