Q:

I want to attach a 2×6 to my garage wall with 5/16-in. lag bolts. What size hole do I need in the 2x and what size in the wall framing? Is there a formula for figuring out pilot-hole size?

Frank Hand, Sun Lakes, AZ

A:

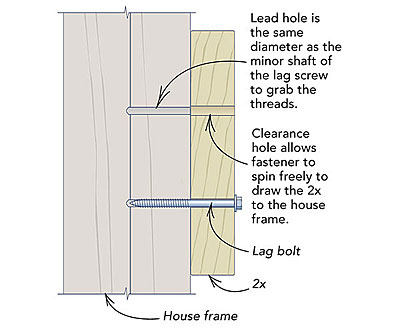

Roe A. Osborn, former managing editor of Fine Homebuilding, replies: There are two types of pilot holes: lead holes and clearance holes (see drawing). As its name implies, the latter provides clearance for the widest diameter of screw, or lag—in your case, 5/16 in. The clearance hole is drilled through the 2x and allows the fastener to spin freely to draw the 2x tight to the framing.

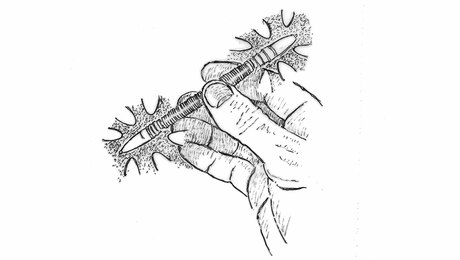

The lead hole is a bit trickier. It should be the same size as the smaller, or minor, diameter that’s between the screw or lag-bolt threads. The folks at Jamestown Distributors (www.jamestowndistributors.com; 800-423-0030), who sell a wide variety of fasteners, told me that as a rule of thumb, the lead hole for a screw should be approximately 75% of the total diameter. For a 5/16-in. lag bolt, that works out to be about 7/32 in. The unscientific approach that I’ve always used is just lining up drill bits with the threaded part of the lag to find the one that is closest to the minor diameter. When in doubt, err on the smaller side. You always can make the hole slightly larger.

Another consideration is the type of wood and its moisture content. For instance, when drilling a clearance hole in fresh pressure-treated wood or green framing lumber, I usually increase the bit size because the hole tends to close slightly after it’s drilled. I increase the diameter by 1/32 in. to 1/16 in., depending on how wet the wood is. Likewise, the people at McFeelys (800- 443-7937; www.mcfeelys.com), another fastener vendor, told me that a larger lead hole may be required for harder woods such as oak. But I always start with the recommended size and ream the hole larger only if it’s really tough to drive the bolt.