Master Carpenter: How to Build a Curved Step

In this video series, master carpenter Mike Belzowski takes us through the process of building a curved riser and tread for a staircase in his own house

In this video series, you’ll see how master carpenter Mike Belzowski builds a curved stair riser by first creating a full-scale drawing of the starting step. He then uses that as a reference to make templates for both the riser form and curved tread. Armed with the templates, he builds the form to laminate the riser, makes the curved tread, and installs both riser and tread at the bottom of the existing stair framing. Watch the entire video series to learn how to pull off a complicated project like this without a hitch.

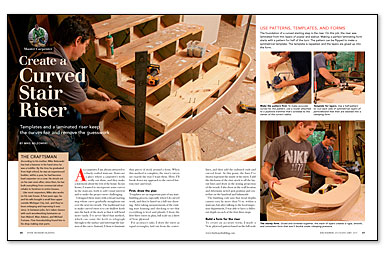

| Read the companion article: Create a Curved Stair Riser  |

View more videos: All Master Carpenter Videos  |

Transcript

Chuck Bickford: My name is Chuck Bickford, and I’m Senior Editor for Fine Homebuilding magazine and producer of the series “Master Carpenter,” and I’m on the road to discover what it takes to become a master carpenter.

Some master carpenters seem born to the trade. When I look at their history it’s hard to imagine them doing anything else. Recently I traveled to Michigan City, Indiana and met Mike Belzowski. If there was anyone born to the trades It’s Mike. According to his mother, his first crib toy was a cats’ paw, and it wasn’t long before he was assembling the family furniture. It’s no surprise, then, that later, when a barn was demolished across the street, Mike took the opportunity to start his career in the building trades.

Mike Belzowski: My dad had an old truck; I was like twelve and he had a little 55 Chevy, and I would drive it across the street, load up as much wood as I could fit in the back there, drive it back to our side, pull all the nails and stack it up, and drive back across and get as much wood as I could, and then I built like a little wood shop with two wood benches and an old coal-burning pot-bellied stove that I took, and I worked in there all the time.

CB: A recurring theme in Mike’s stories about how he basically grew up as a builder was his ability to break down daunting projects into manageable pieces. While Mike has been able to take classes from such luminaries as Sam Maloof, Mark Adams, and Michael Fortune, his strategic approach to projects seems as innate as his early desire to swing a hammer.

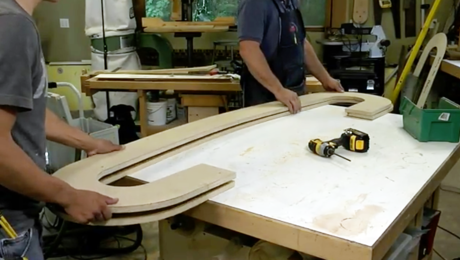

To learn more about his process, videographer John Ross and I visited Mike as he built a curved riser and tread for a staircase in his own house. The riser is laminated walnut under an oak tread and to make them match perfectly, Mike used a single master template to guide his work.

MB: I wanted to incorporate some curves in the staircase, both to add visual interest and to make the project more challenging.

CB: In this video series, you’ll see how Mike approaches this project by first creating a full-scale drawing of the starting step. He then uses that as a reference to make templates for both the riser form and curved tread. Armed with the templates, he builds the form to laminate the riser, makes the curved tread, and installs both riser and tread at the bottom of the existing stair framing. Watch the entire video series to learn how to pull off a complicated project like this without a hitch.

Videos in the Series

-

Master Carpenter: How to Build a Curved Step

-

Building a Curved Step: Episode 2 – Templates

-

Building a Curved Step: Episode 3 – Making Forms

-

Building a Curved Step: Episode 4 – Laminations and Glue-Up

-

Building a Curved Step: Episode 5 – Making the Tread

-

Building a Curved Step: Episode 6 – Installation