If you’re building a solid-surface countertop with a thickened edge, you could buy a bunch of spring clamps to glue that edging on, but there’s a better way.

Jim Chestnut from Miami, Florida, discovered that you can make very servicable spring clamps from 3-in. PVC drainpipe. He cuts the pipe into rings on the chop saw, and then he makes kerfs in the rings using a bandsaw or hack saw (don’t use a tables saw!). Now you can spread them apart and clamp a whole length of countertop edging. A half dozen clamps costs less than a dollar.

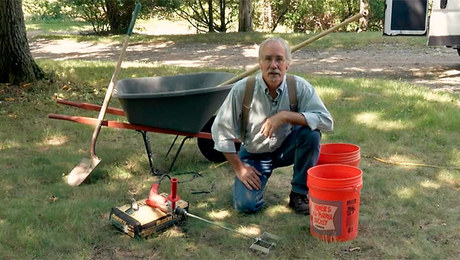

Watch the video above to get more details on how to make and use these homemade clamps.

Watch more video tips:

Make a Custom Holesaw to Remove Stripped Screws

View Comments

The PVC pipe clamps aren't just good for solid surface glue-ups. I use them for loads of clamping jobs - wood gluing, temporary holding, edge banding.... And you can use any size pipe to make clamps. I have some 6" and 8" pipe cutoffs I picked up from a municipal water install and some small 2" central vac cutoffs.

If you drive screws in at an angle to the clamp kerf/opening, you can use the clamps as miter clamps.

And you can use foam-core PVC, ABS and HDPE pipes to make clamps too.

Recently I made some 2 in. wide clamps to hold plastic sheets on a greenhouse frame.

I'm always scrounging through the plumbers' waste pile for more clamp stock.

Question.

Do you increase the clamping pressure by cutting the pipe slices WIDER, and decrease the pressure by cutting THINNER slices? Or did I miss something?

Thanks.

Rather than cut the kerf in the rings, it would be much easier to cut a kerf in the long length of the pipe prior to making the rings using the table saw. Then cut the rings to the length desired using a chop saw.

I seen a lot of things in my day but I can't help that the board stretcher video has to be an April fools prank.

Especially when you claim you stretched the board an additional 12 inches.

Come on guys whats the deal.

I seen a lot of things in my day but I can't help that the board stretcher video has to be an April fools prank.

Especially when you claim you stretched the board an additional 12 inches.

Come on guys whats the deal.

Stew2

DON'T use a table saw to cut a lengthwise kerf in a piece of PVC pipe. The pipe will act as a clamp on the blade, and you'll run the risk of a big-time kickback.

Skyhammer

yes, the wider the pipe cutoff, the more the clamping pressure

Instead of a table saw, what about a jigsaw? For a 3" or larger pipe, the blade wouldn't hit the other side, and you could then cut the pipe to length as needed.

ChadC

Yes, I think a jigsaw could work, and it wouldn't pose the table saw kickback problem. Give it a try and let us know how it works. Thanks for the feedback.

Chuck