If you need to glue edgeband to a wide shelf or countertop and you don’t have enough pipe clamps, you could go out and spend all your money on new clamps, but there’s a better way.

This is a tip from Michael Hoff from Boxborough, Mass., who discovered an endless supply of long clamps in the scrap bin right there in his shop. They’re made out of 3/4-in. plywood, and they could not be simpler to make. Here’s what he does:

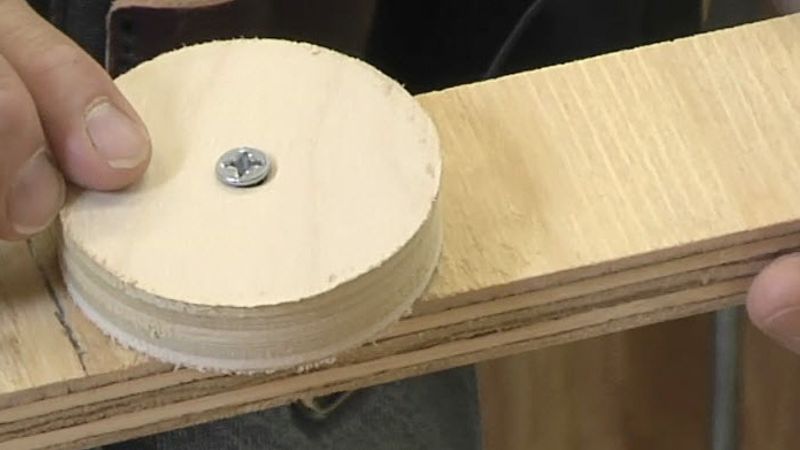

Each one of these clamps consists of a 2-in. wide, 3/4-in. thick stretcher, and it has to be at least a foot longer than the width of the workpiece you’re working on. At one end is a 2-in. by 4-in. plywood block, and it’s attached with a single number-ten wood screw 1-1/2-in. long. At the other end, there’s a plug from a 3-in. hole saw, also held on by a number-ten screw. The distance between the edge of the round plug and the block at the other end is just about 1/16-in. to 1/8-in. longer than the width of the workpiece and edgeband combined.

Here’s how the clamp works: Put the clamp on perpendicular to the workpiece and then just lever it to one side or the other. As the block and plug come in contact with the edges on both sides, push a little more and the clamp just sucks the banding right ino the workpiece and holds it in place.

This is an amazingly adjustable system. I’m astonished at how I’m able to make minute adjustments before the glue has a chance to set up.

Michael, that is an awesome tip. Thank you so much for sending that in.

View Comments

Guys, you might be interested in checking out fine luxury homes by Brejnik Fine Homes (www.brejnik.ca). They build fine luxury houses. Brejnik team consists of qualified and trusted: Architects, Interior Designers, Appraisers / Lenders, Trades & Suppliers, Geo-technical engineers, Structural Engineers, Arborists, Landscape Architects, Pool & Water Feature Specialists.