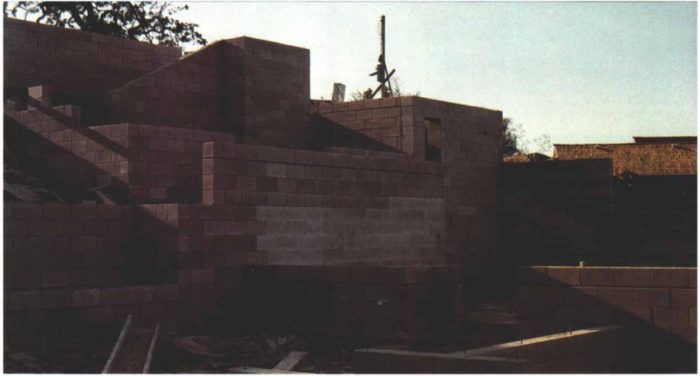

Synopsis: An architect makes the case for dry-stack block walls. They are made from precisely manufactured concrete blocks that are stacked into walls without the need of mortar joints and then filled with grout. Material costs are higher, but labor costs are much lower than typical block construction.

Designers have been trying for years to develop a mortarless concrete-block system that could be used by unskilled builders. The concrete blocks in use today look quite uniform, but their dimensions actually vary so much that mortar is necessary not just to hold them together, but also to make up for their irregular sizes. Mixing and applying the mortar to the joints in a block wall require skill and time, and the process accounts for 20% to 30% of the material and labor in a masonry project. Manufacturers have recently developed mortarless, interlocking block for industrial and commercial buildings. I use it in house construction. It’s called drystack block, and it can be laid up as easily as the plastic toy blocks in a Lego set.

What is a dry-stack block?

Dry-stack blocks look very much like ordinary concrete blocks, but they are consistently a full 16 in. long and 8 in. high (regular blocks are an inexact 3/8 in. less in each direction to allow for the mortar joint). During the manufacturing process, the dry-stack blocks I use are sent through a machine that grinds the top and bottom surfaces to a tolerance of 0.005 in. These parallel, exact and smoothly ground surfaces are what allow the block to be laid up so regularly without mortar.

Most dry-stack blocks have interlocking tongues and grooves at their ends to help align and secure them during placement. Besides standard blocks, there are also bond blocks for bond beams (these have knockouts to accept horizontal rebar), and half blocks. Special corner blocks are manufactured without tongues for finished outside corners. Where the block remains exposed, its edges are usually chamfered to create a hand-tooled corner that’s less likely to chip. It is also possible to have the face of the block ground and sealed to create a smooth, marble-like appearance.

Differences between ordinary mortar-laid block and the dry-stack

There are three essential differences between the ordinary mortar-laid block and the dry-stack. First, the dry-stack method uses mortar only at the joint between the footing and the first course of block. This mortar joint at the base lets you set the first course absolutely level. Second, ordinary block is usually grouted (filled with concrete when the wall is complete) in only the cells containing reinforcing steel (rebar), while dry-stack blocks are usually grouted in every cell. This locks the blocks in place, and also fills the bond beams completely without having to pour them individually.

Third, you have to be careful with ordinary block walls to be sure that fallen mortar (as distinct from grout) doesn’t hang up in the rebar or clog the bond-beam channels. This usually means that you have to build the wall in 4-ft. vertical increments so that the grout completely fills the appropriate cells. A drystack wall, however, can be grouted all at one time because there is no mortar to clog the steel or to plug up the cavities. Grouting tall dry-stack walls all at once can save a lot of time, especially if you use a concrete pumper.

For photos and more on dry-stack blocks, including cost comparison, waterproofing, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Anchor Bolt Marker

Original Speed Square

Smart String Line