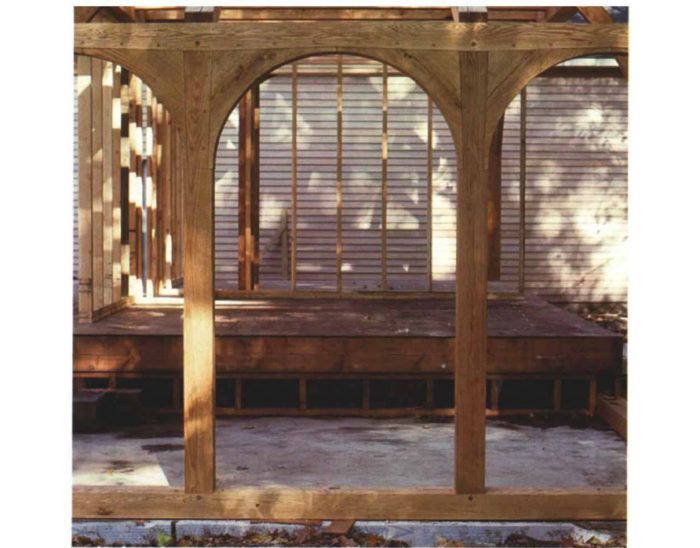

Curved Timber

How one timber framer hews, bandsaws, and steambends straight stock into curves.

Synopsis: A general discussion of various ways that timber-framers make curved building components from heavy timbers. The author covers steam-bending, the use of a bandsaw, and even hand hewing with a broadaxe and adze.

The process of turning trees into lumber is largely a matter of turning irregular curves into smooth, straight lines. It’s an uphill battle, as any woodworker can tell you. So if straight and square is the lumberman’s Holy Grail, why is curved work the highest expression of the woodworker’s art? Windsor chairs, Chippendale highboys, the flowing lines of a wooden hull and the soaring heights of a vaulted church all attest to this mystery. The process is fraught with paradox: in order to round the wood, I must first make it straight and square, yet sometimes when working on a curved brace, it seems that I am trying to turn lumber back to a tree again.

The only curved timbers that start out as such are found curves, which are curved trees or limbs that are sawn or hewn along their natural lines. In the medieval heyday of timber framing when elaborate curved work was common, supplying curved stock must have been an established business. Even today, some boat builders have a standing order for hackmatack knees—the curved, exposed roots and limbs of larch trees. Found curves are also seen in matched pairs as wind braces or cruck frames.

Curves shaped by hewing

Shaped curves are sawn or hewn from straight stock. These days most of the work done by me and my partners is bandsawn, but once we did hew a curve in a timber, serendipitously. A friend wanted the focus of a timber-frame addition to be a 20-ft. long summer beam, hewn from a tree in his woodlot. We felled and hauled in the only tree large enough to make the required 8×12. After we crosscut and peeled it, the trimmed log was predictably smaller and less straight than it looked on the stump, and it would have made a very waney 8×12. We decided to hew only three sides, leaving the bottom of the beam in the round. After rough hewing the three sides with a 12-in. broadaxe, we shaved them clean with a lipped adze. The completed summer beam was handsome and reasonably square and straight, and we quit for the day well satisfied.

But by the next morning, the tension in the undressed sapwood side had pulled the beam into a curve and the midspan of our formerly straight summer was now displaced more than 2 in. out of line with the ends.

Since attempts to straighten the timber by additional hewing would probably only cause it to bend further, we concluded that we’d found a new method for curving timber and had better make the most of it. We raised the joists so that their tops would clear the high point of the summer beam. The counterpoint of the straight joists against the gently curved summer beam gives a slightly domed effect to the room.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

100-ft. Tape Measure

QuikDrive PRO300s

Smart String Line