Economical Framing

To conserve materials and save money, avoid overbuilding and design on 4-ft. modules.

Synopsis: This is an introduction to the Optimum Value Engineered house, a method of framing devised in the 1970s to reduce waste of construction materials. The author, director of industrial engineering on the project, explains the approach and introduces such ideas as economical corner framing and the use of plywood headers.

Back in January 1973, the National Association of Home Builders’ (NAHB) Research Center was commissioned by the Department of Housing and Urban Development (HUD) to devise a cost-effective framing system. I was the director of industrial engineering on that project, and what came out of it was the Optimum Value Engineered (OVE) house.

Optimum Value Engineered house

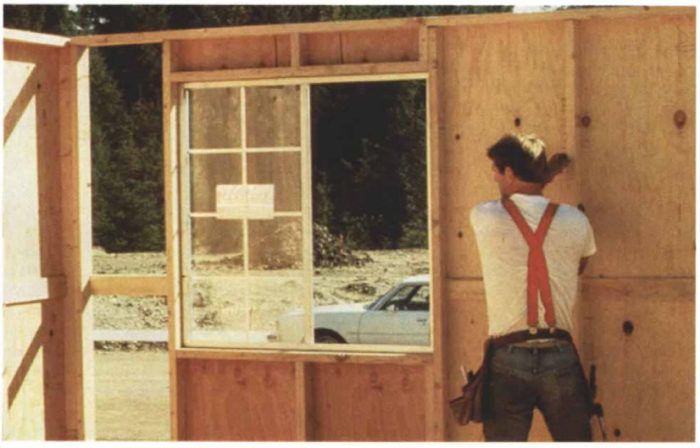

OVE is like a streamlined version of conventional wood framing. NAHB took a long, hard look at waste—materials that added nothing to the strength, durability or marketability of stickframed houses. The OVE house was built without superfluous materials. With less material to put into the house, there was less work to do, so money was saved on both materials and labor.

The OVE house proved to be safe, marketable and inexpensive: everything HUD wanted in 1973. Nowadays, with the environment getting almost as much attention as the economy, DVE makes even better sense. Because the system reduces the amount of lumber products in a house, it conserves natural resources.

Most builders, regardless of production volume and price of their homes, will find the OVE approach to framing easy to incorporate. Many builders throughout the country have already instituted many of the lumber- and plywood-savings methods prescribed by OVE. Most OVE methods are accepted by the major model building codes, but you should check with your local building officials before trying these methods.

Materials-based design

If you want to give OVE a try, start with design. A cost-effective floor plan has the most floor area enclosed by the least amount of exterior wall. For example, say you’ve got two homes, both of them with 1,200 sq. ft. of floor area. The first home has a 20-ft. by 60-ft. floor plan, so it’s got 160 lineal ft. of exterior wall. The second home has a 30-ft. by 40-ft. plan; it’s got 140 lineal ft. of exterior wall: 20 ft. less wall enclosing the same amount of floor area.

When designing a house, the goal should be to keep the floor-to-wall ratio as high as possible. In the example, the first home has a 7.5:1 floor-towall ratio; the second has a 8.5:1 ratio.

Lumber and sheet products—plywood, oriented strand board, particleboard, gypsum wallboard, etc.—are produced in 2-ft. increments. Minor adjustments on the plans can make more efficient use of lumber and sheet products, reducing waste and eliminating framing members.

The most cost-effective design places all exterior walls and as many interior walls as possible at 4-ft increments, or modules. This major module is divided into minor modules of 2 ft. This scale matches the width of most construction sheet materials and standard lumber lengths, thereby eliminating cutting labor and reducing scrap. Consider a wall that’s 22 ft. 9 in. long. This wall takes just as much plate lumber and sheathing to build as a 24-ft. long wall (remember, lumber products are produced in 2-ft. increments). However, the shorter wall creates almost 4 ft. of scrap plate lumber and over 9 sq. ft. of scrap sheathing. In addition, at least one stud bay will be narrow, making the insulation contractor cut a batt to fit. The longer wall actually costs less to build.

Traditionally, roofs have been designed without much consideration for sizes of framing members and plywood sheathing. Plans are drawn for 4-in-12, 6-in-12 and 6-in-12 pitches without weighing the effect on efficient use of lumber and plywood. But there’s nothing magical about whole-number roof pitches. Consider drawing a roof-sheathing layout that takes maximum advantage of the 4-ft. by 8-ft. dimensions of plywood and let the pitch fall where it may. This roof design eliminates plywood and lumber scrap plus the associated labor for cutting.

For photos and more on reducing excess lumber in walls, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Plate Level

Sledge Hammer

Smart String Line