Choosing Boilers and Controls for Warm Floors

You don't want the noise and dust associated with furnaces; you want the comfort of radiant heat. Here are some options for heating the water and getting it to your floors.

Synopsis: Here’s a look at how radiant-floor heating systems work. The author, an engineer, explains a number of options for heating and circulating water, using clear diagrams.

When people think of radiant-floor heating, the first image that comes to mind is a labyrinth of tubing filled with warm water snaking its way beneath a floor. But a warm floor is only part of the overall heating system. How that warm water is produced, controlled, and delivered to different parts of the house is equally important. The comfort that radiant-floor heating is famous for is achieved only when all parts of a system are properly matched, installed, and functioning in unison.

In my last article, I discussed ways of installing hydronic radiant-floor heating. Now I’ll describe ways of producing and delivering heat to the floors and point you toward the system that will work best for you.

The basic parts of the system

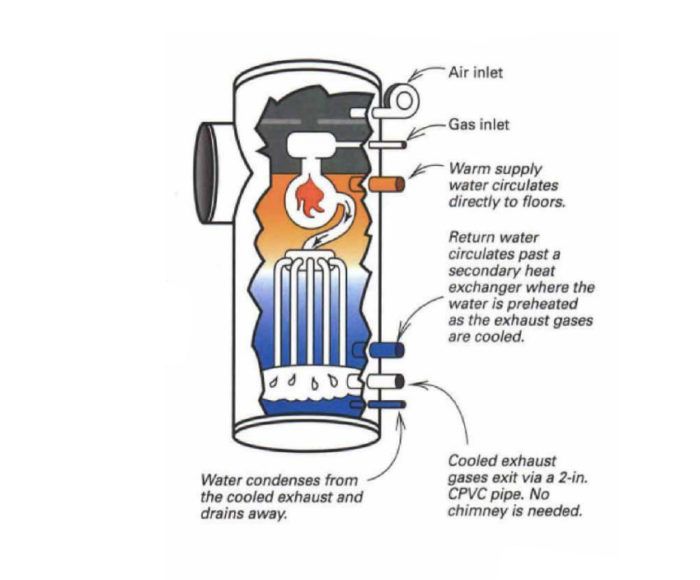

In the simplest terms, the typical hydronic radiant-floor heating system operates by first producing heat and then transferring that heat to water inside the heat source. Heat sources include conventional boilers, condensing boilers, and hydronic heat pumps.

A circulator (a special type of pump) then pushes the heated water to the supply piping. But because heated floors require warm water instead of hot water, the heated water usually passes through a mixing device that reduces its temperature by blending it with cool water returning from tubing circuits in the floor.

The warm water is then pumped through the distribution piping and eventually enters one or more manifold stations. The supply manifold further divides the flow among several floor-tubing circuits, where heat is released to the flooring materials as the water flows through the tubing. Each circuit is connected to a return manifold that collects the cooled water. The remainder of the cooled water that isn’t mixed with the incoming water is routed back to the heat source to begin the cycle again.

Conventional boilers adapt easily to radiant-floor heat

Conventional cast-iron and steel boilers have long been the staple heat source for hydronic heating. Although they produce relatively high-temperature water, conventional boilers easily adapt to lower-temperature requirements of floor-heating systems by the mixing process I just described. Their ability to produce high-temperature water makes them a good choice in homes that have both radiant-floor heat and high-temperature heat.

In a conventional boiler, the water is heated in a steel or cast-iron heat exchanger, a series of chambers suspended above an oil or gas flame. Other high-temperature boilers called low-mass boilers use copper tubing with fins instead of a chamber. Low-mass boilers heat water more quickly, and they have a definite size and weight advantage over their cast-iron and steel cousins. But the overall efficiency of low-mass boilers is about the same as conventional boilers.

Modern gas-fired and oil-fired boilers operate with average efficiencies in the 80% to 85% range. There are dozens of manufacturers and hundreds of models to select from, so don’t make your choice based on price alone. A well-designed, properly serviced cast-iron boiler can last for over 30 years. So make sure you can get local service for the boiler you choose.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Musings of an Energy Nerd: Toward an Energy-Efficient Home

Homebody: A Guide to Creating Spaces You Never Want to Leave

Not So Big House