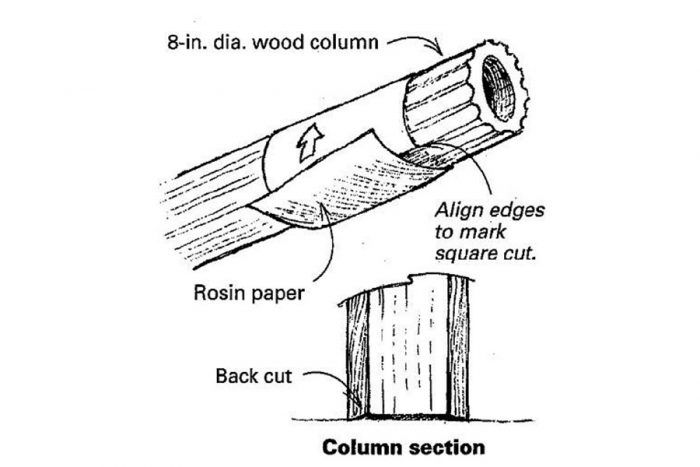

Recently, I had to cut an 8-in. dia. wood column to length. The trick was to make sure the round column was cut exactly square. Because it was too big for my miter box, I started mulling over my options. Then a colleague recommended a simple solution. All it required was a length of paper with a straight edge long enough to wrap around the circumference of the column.

As shown in the drawing, I used a piece of rosin paper to encircle the column at the required length. When the edge of the paper was aligned, I marked my cut and used a jigsaw to lop off the unwanted portion of the column. Note in the section of the column how I angled the jigsaw a bit to create a slight back cut to ensure a tight fit where the column sits on its base.

—Patrick A. Molzahn, Oregon, WI

Edited and illustrated by Charles Miller

From Fine Homebuilding #117

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Angel Guard Deck Demon

Drill Driver/Impact Driver

Cepco BoWrench Decking Tool

View Comments

I use a similar method for marking Sonotubes™ for cutting except that I use about a 12" wide piece of aluminum roll flashing. Less potential for distortion than paper and it provides a good edge for marking. Once lapped over itself a good distance and insuring both edges are aligned, the marked line will be square to the tube (or column).

Who has a tip for squarely cutting a tapered tube?

T^5 - Square-cutting a tapered tube is much more of a challenge. Using flashing as I suggested for a cylindrical tube won't work unless it's trimmed appropriately. It's edges would have to be trimmed to a curve. The radius of that curve will depend on the amount of taper, and if my geometry memory serves me correctly the curve would actually be elliptical. The exact dimensions would be controlled by the taper and the diameter at the cut line.

I don't know of an old-school method. I would model it in CAD and create a template that I could plot full-size on paper and transfer to some flashing.

The curve can't be elliptical because that would imply a change in the curvature of the column- while the curvature does change with the height, it's constant at any given elevation.

Yankee's approach would work- oldtime HVAC guys did it all the time. But most of us don't have those skills these days. I would mark the height on the column at several places, then wrap a string or a flexible strap (a really big rubber band?) around it and trace a line. Maybe put in a few brads to make sure the string doesn't wander.

Another way to cut a cylinder is to put the lip of a speed square along the length of the cylinder and use the other edge to guide the saw, almost like cutting a 2x. My intuition says the same trick would work with an adjustable square set at an angle determined by the taper of the column, but intuition doesn't tell me what that angle might be.