Working With Rebar

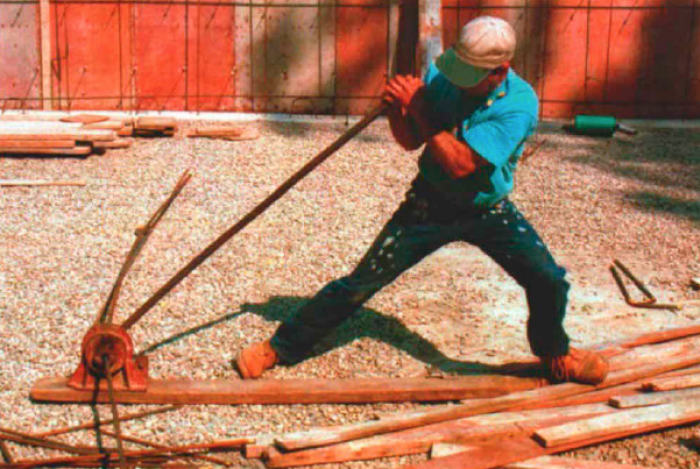

The bones beneath concrete's muscle, rebar has to be cut, bent, and tied properly to do its job.

Synopsis: Steel rebar is commonly used to strengthen concrete structures like foundations. The author describes what types and sizes are available, how to cut and bend it, and how to place it properly.

Why should you have a spare tire in the bed of your truck? It’s not required by law, and the truck will run just fine without it. Using essentially the same logic, some people might ask why we use rebar in our residential foundations. Many houses are built without it (East Coast building codes don’t require it), and if a house is built with rebar, building inspectors often don’t inspect its placement.

The simple answer is that rebar is cheap insurance against the potential problems that can develop after concrete is poured or, worse, after the foundation has been back-filled. A foundation that has gone wrong is extremely expensive to repair. Just to be safe, my crew and I reinforce concrete in footings and walls, in piers and columns, and in structural slabs, and we also use rebar to tie new work to old.

Concrete used in residential construction is usually specified in a range of compressive strength in 500-lb. increments between 2500 psi and 4000 psi. It’s obvious that concrete can support phenomenal compression loading. However, when it is under tension or shear forces, concrete has lower values compared with other common construction materials. If the underlying soils are of uneven densities, differential settling beneath the foundation can cause large cracks in the walls. Concrete is also subject to shrinkage cracks, especially when poured with a high water-to-cement ratio. When properly sized and embedded in concrete, rebar partially compensates for these deficiencies. (Remember that excess water produces lower-psi concrete that is weaker and more prone to shrinkage. Even reinforced with rebar, high-water-ratio concrete shouldn’t be used.)

Sizes and grades of rebar

Rebar comes in many sizes and grades. In residential work, we mostly use bar sizes #3, #4 or #5. These sizes translate to the diameter of the stock, measured in 1/8-in. increments; #3 bars are 3/8 in. in dia., #4 bars are 4/8 in. (1/2 in.), and #5 bars are 5/8 in. The grades 40 and 60 refer to the yield (tensile) strength (40,000 psi and 60,000 psi, respectively). Grade 60 is harder to cut and bend. Both grades are priced the same. The designer usually specifies which one to use for a particular purpose. If the grade is not specified, I buy the softer grade 40 for short lengths and bends, and grade 60 for long straight runs with few or no bends.

For more photos, illustrations, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Smart String Line

Plate Level

Anchor Bolt Marker