Somebody always takes things the wrong way

After reading all the letters about Barbara Flanagan’s essay (“Taking Issue,” FHB #123, pp. 6,8), I am once again reminded of why I hesitate to write articles for publication anymore. Somebody always takes things the wrong way, don’t they?

I’m a woman, and I do massive building projects by myself, but I didn’t take offense at the essay. In my best of all possible worlds, somebody else would do all this work for me, and they’d do it to meet my standards. But as was the point in Flanagan’s essay, it’s hard to get good help these days. Perhaps Flanagan should have used less gender-specific terminology, but she said she was an architect, not an English major. My mother, who was an English major, says that you shouldn’t take every word literally.

Men and women answer to different social stereotypes. The downside for women do-it-yourselfers (I don’t presume to speak for professionals) is constant wisecracks at the Home Depot checkout. “You mean you’re doing this by yourself?” “You must be smart. I never met a girl that knew how to build a deck.” “You mean you own power tools?” They usually say these things after they watch me lift down a cartful of soaking wet pressure-treated 2x8s from a shelf over my head by myself.

People ask me all the time, “How did you learn to do all this?” I say, “I watch a lot of public television, and I get Fine Homebuilding.” How does anybody learn it? I also consult manufacturer Web sites, but I think following published instructions might be for sissies.

And therein lies the serious downside of sex-role stereotyping for men. Lots of building techniques I have developed for working by myself would never work for a crew of men because they aren’t macho. Apparently, clamps on a job site are for sissies. Real men just hold the deck joist up with one hand and shoot a nail in it. If it comes out half a bubble off plumb, it’s close enough. Safety glasses, gloves, back support, levers and fulcrums, and predrilled screw holes are all for girly-men. Matching a running line of lap siding around a corner might be for sissies, too, I think as I try to excuse a particularly irksome mistake made on my house recently by a man with a tattoo the size of a large cat.

I disagree with the letter in your last issue that said your magazine is “spoon-feeding the overweening ego that some men already have and perpetuating the myth that women are nothing but helpless bystanders of society” (FHB #125, p. 6). I had to look up overweening. It means arrogant. If I had a good synonym for lighten up, I would work it in here. I think it’s men who don’t read your magazine (or just don’t read at all) that are perpetuating the myths that safety equipment is for wimps and reading instructions is for babies—ideas much more harmful than that women are helpless. I remember seeing a woman among the line of folks standing up a wall in a photo a few issues ago. She looked as if she was helping. And I have personally used countless tips that I read in your magazine. They didn’t say, “Women, do not attempt this technique. You could break a nail.”

It takes a strong example to affect changes to sissy stereotypes. They had seat belts in Indy cars for years before European sports-car racers finally agreed to wear them. I guess it’s going to take more than Norm Abram saying, “But first we should take a moment to talk about shop safety.” Maybe if Norm got a tattoo the size of a large cat. …

—Barbara Tomlinson, Atlanta, GA

You can rustproof the inside of your compressor

I bought a compressor to power a nail gun for building my house. From the start, I took care to drain the tank every week and noted each time that the water was brown with rust. This concerned me.

By fortunate coincidence, a friend was involved with a company that rustproofs cars using a high-tech chemical spray. Early this year, I asked if this material would also protect the inside of the tank. “Sure,” he replied. “And it’s available in aerosol spray cans.” So I obtained a can.

One fine day last spring, I made sure that the tank was drained thoroughly and that the pressure was zero. I then uncoupled the copper tube that runs from the compressor at the tank. Through the opening, I sprayed a generous amount of the rustproofer using the 4-in. extension tube that accompanied the can. The material foamed as it left the tube, so I sprayed enough to produce a substantial amount of liquid. I then reconnected the tube and moved the tank around so that the rustproofer contacted the entire interior surface. I drained the excess and let the tank dry.

When I drain the tank these days, the water comes out crystal clear. In the United States, the product to look for is Corrosion Block, available at automotive stores (I am told). In Canada, contact your Rust Check dealer for an aerosol can.

—Ian L. McQueen, Saint John, NB, Canada

Says compressor letter may have saved his life

Your August/September 1999 issue contained a letter from James D. Nelson of Woodville, Wisconsin, regarding air-compressor draining that may have saved my life, or at the least serious damage to my home or garage (FHB #125, p. 12).

I have had an Emglo AirMate compressor, model AM77 HC4V, in my home shop for at least 15 years. I have routinely cleaned the air filter, checked the oil and pulled the pressure-relief valve on the lower left side of the bottom tank to, I thought, drain condensate. I either never knew or had forgotten that there is a drain valve directly under the bottom tank and completely out of sight that really drains the tank. Talk about fat, dumb and happy!

Today, after having read the letter and been nudged my wife, who also read it, I decided to tilt the tank when I drained it. I almost painted a floor with the rusty water that gushed forth. Taking it outside and continuing to tilt and drain with the pressure-relief valve open, I finally noticed the long hidden drain valve on the bottom of the lower tank. You can imagine my shock.

After thorough draining of the compressor, I have attempted to dry out the tanks by running the compressor with the drain valve open. Now I plan to find a shop that can give me an over-pressure check to verify that the tank is still safe to use. Needless to say, I am thankful for your magazine, Mr. Nelson’s letter and my wife’s nudge. It shows that along with all our skills, we need a little luck.

—Verge Givens, via e-mail

Quick connectors on air hoses can also disconnect quickly

One more item for your safety file when using a nail gun. The use of quick connectors on hoses (to connect two 25-ft. hoses to make a 50-ft. length) can be unsafe.

In my case, I was building an addition to a pole barn in the country. The addition was built over the natural grade of grasses and weeds. Toward the end of the day, I picked up the nail gun from the board on which I had carefully laid it to try to keep out the dirt. I started to raise the gun, but the length of hose stopped me. I knew I had plenty of hose so I gave it a slight tug. That slight tug was enough to cause a weed or twig to release the connector. The male end of the hose took off like a rocket. It whipped up and back, ending its flight shortly after removing the top portion of one of my lower front teeth.

—Tom Phillips, via e-mail

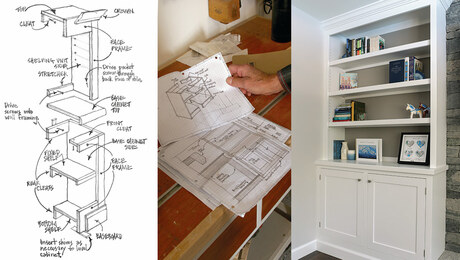

Thinks built-ins should be assembled in the shop

As a longtime cabinetmaker, I was interested in Kevin Luddy’s article about built-in hutches (FHB #125, pp. 80-83). I think it is a strategic error to assemble the carcases of the cabinets on site rather than in the shop. With shop assembly, the tedious process of shimming and fastening parts to the walls can be eliminated. This procedure requires the use of backs, but the minimal cost of plywood or hardboard backs is more than offset by time savings on the job site.

Another thing I would suggest is that carpenters never use a toe kick on a piece of living-room furniture. No one is going to belly up to these things as if they were kitchen cabinets. Run the face frame to the floor, and duplicate the room’s baseboard across the front. It looks much better, is more elegant and contributes to the look of a custom piece of furniture.

—W. Geoffrey Seeley, Washington, DC

Take B-6 for carpal-tunnel syndrome

As someone who has been suffering from carpal-tunnel syndrome for over ten years, I read your “Breaktime” discussion about it (FHB #125, p. 14) with interest. I’d like to add the following.

Wrist splints help. I think the best splints are those from Robby (931-380-2092). They’re made for bowling, and you can pick them up at the local pro shop. These splints are inexpensive (compared with the physical-therapy splints) and come with Velcro fasteners for easy wearing and metal plates that hold the wrist in a relaxed, open position to give the median nerve rest. I use the leather ones because they wear well and are warm. Wear them when you go to sleep and take them off in the morning. I’ve had trouble using them on the job because they restrict mobility and you end up fighting them, making the wrist work even harder.

Most important, start up with vitamin B-6, 100mg per day. This is now the recommended therapy prior to surgery. It has been proved in placebo-controlled, double-blind tests in Europe. Unfortunately, the reason this therapy is not well known in the United States is that the pharmaceutical companies (which sponsor most of the research on drugs, and hence most of what gets printed in the medical journals here) cannot patent a vitamin, so B-6 has not received the research funding needed to get it into the medical journals and into our medical professionals’ minds.

It takes about four to six weeks to get relief, but B-6 can reduce the inflammation of the nerve and often get rid of symptoms totally. I did have numbness in my hands, especially at night while asleep. I now have no numbness and can work with my hands at least four hours a day. If I abuse my wrists and numbness starts to return, the splints, B-6 and reduced wrist time put things back to normal within days.

B-6 is painless, inexpensive and water soluble; any excess is flushed out of the body. But don’t take more than 100mg a day.

—Susanne Richert, Ocean Grove, NJ

A good book on repetitive-strain injuries

Although I didn’t participate in the “Breaktime” discussion about repetitive-strain injuries and carpal tunnel, I read about it in the August/September 1999 issue (FHB #125, p. 14) and felt the need to comment.

I’ve been a builder since 1981, and like most builders, I abused my body for many years—six days a week and many 12-hour days. It wasn’t until I was doing months of stonework on a very large house that I began to experience the symptoms of repetitive-strain injury (RSI). Terrible pain in my arms would wake me during the night. Numbness would come and go. My grip was getting weaker, and my manual dexterity was eroding. It really scared me because I thought my building days were over.

I went to the library and checked out a book called Repetitive Strain Injury by Dr. Emil Pascarelli. It is a small book, but I highly recommend that every builder, worker, craftsman, musician, clerical worker, administrator and boss read this book.

Basically, the author says that if we learn to listen to our bodies and not abuse them, we won’t suffer. Instead of pushing relentlessly, we must take short breaks and stretch our muscles to keep them from getting stressed. He described my symptoms exactly. He said that if I didn’t stop the activities that were causing the stress, then I could do permanent damage to my arms, which even surgery could never correct. That one sentence got my attention.

But he also said that most RSI does not need surgery, medicine or even a doctor. With proper stretching exercises, the injury could be completely reversed and allow the body to heal itself. He had pictures of many many such exercises in his book, which I started to do faithfully.

In a few weeks, I was completely recovered. All the pain and discomfort were gone, and the fear as well. Now when I work hard, I listen to my body when it starts to complain, and I take a break to stretch. Just a minute or two. Please, if you read this and if you are experiencing these symptoms or know someone who is, read the book and do yourself a great favor.

—Elliot Gesang, Graham, WA

Likes his Makita sliding compound-miter saw

I’d like to respond to your article “Survey of Sliding Compound-Miter Saws” (FHB #125, pp. 84-89) and offer my defense of the Makita LS1011. More expensive and bigger is not always better. This saw has been bouncing around in my Weatherguard toolbox for over eight years (it fits easily). It weighs only 35 lb., so I don’t need a back brace to lift it out of the truck or to carry it to a second-floor bedroom to install crown molding. After years of abuse, this saw cuts everything from 4x4s to fine trim as accurately as the day I pulled it out of the box.

Time-testing, ease in handling and good value should give this saw a high rating.

—Nicholas Lieb, Absecon, NJ

Be careful mixing acid and water

The article about concrete countertops in your last issue (FHB #125, pp. 62-69) is excellent, but a potentially deadly/dangerous practice is described. On p. 69, the article describes preparing the top for staining with a diluted acid solution and says the solution was made by adding 10 parts water to 1 part acid. This manuever is dangerous. Never add water to acid as a thermophilic/explosive reaction will ensue. Acid must always be mixed to water. I remember this by saying A to W, not W to A. It would be awful for some well-intentioned person to make this mistake and have the entire bucket blow up in his/her face.

—Michael Benno, via e-mail

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Reliable Crimp Connectors

Handy Heat Gun

8067 All-Weather Flashing Tape