Here in Montana, builders get calls from clients about projects ranging from traditional stick-built homes to full-scribe log homes, and everything in between.

On a recent job, my company built a house with “milled” logs, which have a tongue on top and a corresponding groove milled into their bottom. In this case, the log supplier neglected to bore holes for the threaded rods that run from the foundation to the top course of logs—and this was a large, two-story house.

For the logs to be stacked correctly, we needed to drill the holes for the threaded rods accurately every time. Enter the drill jig.

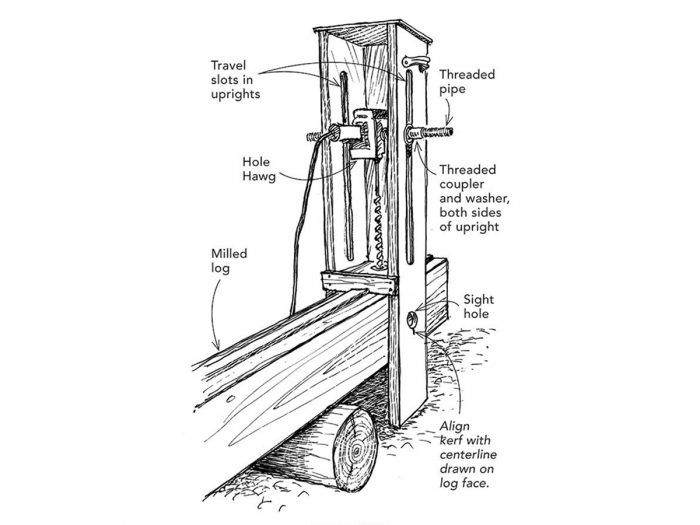

We used the threaded holes on each side of a Milwaukee Hole Hawg to receive two fully threaded pipes. As shown in the drawing, the pipes passed through slots in the 2x uprights. Threaded couplers and washers on both sides of the uprights kept the Hole Hawg in correct alignment and allowed the tool to travel on a vertical axis.

To line up the placement of the jig on the log, we pulled our measurement to the hole locations, then squared a line down the face of the log. We then placed the jig over the target, lined up the sawkerf in our sight hole on the side of the jig, and were ready to drill. Once set, the Hole Hawg traveled downward in perfect formation every single time—and this job lasted for a couple of months.

—Hunter Bell, Roberts, MT

Edited and illustrated by Charles Miller

From Fine Homebuilding #210

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

8067 All-Weather Flashing Tape

Handy Heat Gun

Affordable IR Camera