My foray into the world of circular trim began with the round window over my front door. The window looked nicer than the hole it replaced, but it had no trim. At first glance, matching the other windows seemed like it would be easy; the trim is just 1×4 flat stock with a simple bead on the inside edge. But I knew the process wouldn’t be as simple as it seemed. I considered buying the casing from a local mill shop. I checked around and got quotes ranging from $150 to $600 for custom circular casings, none of which matched the existing trim profile on my house. So I decided to make it myself. I engineered the horizontal router setup first, checked it on scrap material, then started on the actual trim. As the rest of the house’s trim was cellular PVC, I cut the stock from a full 4×8 sheet of 3/4-in. material I purchased for about $165.

There are several benefits to making your own circular moldings. You’re not limited to standard sizes, you avoid premium one-off production fees, and the molding is delivered on your schedule. Making your own moldings also broadens your skills and gives you a couple of useful router setups when you are finished.

Two cuts define the blank

After establishing a centerpoint in the stock, drill a 3/8-in.-dia. hole and tap in a 11/2-in.-long steel pivot pin of the same diameter, which will protrude above the surface about 1/2 in. The stationary end of the adjustable circle-cutting jig fits tightly onto the pin. Attach a router with a 3/4-in. mortising bit to the mobile end, dial in the correct outside diameter, and begin a series of increasingly deeper passes. It’s a good idea to stop occasionally to vacuum the debris so that you can see what you’re doing. After checking your measurements for the inner circle, adjust the base and cut the inner circle.

Cut the outside diameter

Cut the outside diameter  Cut the inside diameter

Cut the inside diameter

Trick of the trade

Adjustable circle-cutting jig

You can buy a circle-cutting jig for a router for about $45. Typically, it’s an elongated teardrop shape with lots of indexed holes at one end that determine the radius of the cut. The author wanted a fully adjustable jig, so he made one from two pieces of clear polycarbonate that slide past each other. Two knobs and bolts lock the two pieces together. The cost for materials was about $50. The knobs were bought online (www.leevalley.com).

Cut the bead sideways

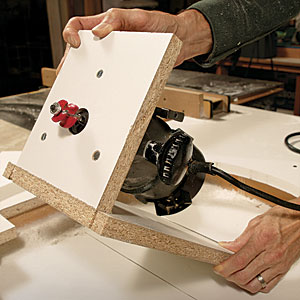

To cut the bead on the inside edge of the circle, a horizontal router setup is the best way to go. The stock lies flat on the table, which makes it safer to cut and limits wandering and vibration.

Due to the relatively tight radius of this particular window trim, I realized that commercially available router bases would be too wide to let the stock get close enough to the bit. I decided to make a horizontal jig with a base a bit wider than the router baseplate.

I mounted the jig into a recess in my tablesaw outfeed table and mounted the router so that its arbor height would match the height of the stock when laid on the table. Because the cutter needs to be spinning when it enters the stock, I hinged the opposite end of the L-shaped base to my worktable so that I could lower the spinning bit into the stock.

To secure the stock, I cut the matching outside radius in three pieces of scrap and screwed them to the table, allowing just enough clearance for the blank to rotate past the cutter without any slop.

Mount the router in hinged horizontal jig

Mount the router in hinged horizontal jig  Lower spinning router onto workpiece

Lower spinning router onto workpiece

It’s like a record on a turntable

Because the bit must ease into the work, turn on the router and lower it slowly into the material. When the guide bearing is resting on the stock, the router base should be flat against the table. Begin rotating the stock clockwise into the rotation of the cutter. As with machining any other material, keep the feed rate and pressure as constant as possible. Use gloves with grippy fingertips to increase the traction on the stock, which can be slippery. The author’s beaded circular molding was blemishfree on his first attempt.