Mineral wool vs. Fiberglass insulation – some impromptu research at the International Builders’ Show

The timing of this year’s International Builders’ Show was convenient for me. I was able to spend some time on the show floor talking to manufacturers about mineral wool insulation, sometimes called rock wool insulation–a topic that Fine Homebuilding will be covering in an upcoming issue. This isn’t a new insulation product, but it is gaining grown here in the US, thanks to some improvements in distribution from manufacturers such as Roxul, CertainTeed, Thermafiber, and others.

So why go with mineral wool insulation?

If you ask me, it’s easier than fiberglass batts when it comes to cutting, handling, and fitting into framing cavities. Others will tout its benefits of shedding water and being fire proof. But I knew all of that before setting foot on the show floor. But there are a couple of things I learned during my discussions with fiberglass insulation manufacturers that bear some further investigation. (If you ever want to play devil’s advocate when it comes to choosing a product, just ask their competitors.)

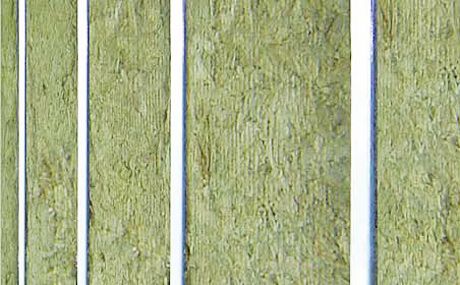

Why are mineral wool batts more rigid, firm, and dense than fiberglass batts?

The answer to this one is that mineral wool batts are more firm and dense out of necessity, not design. When glass fibers are spun to make fiberglass batts, the fibers are long, and therefore hang together easily to make a cohesive batt. With mineral wool, the fibers are much shorter, so in order to keep the batts in one piece, they have to be packed to a higher level of density.

What makes mineral wool a better soundproofing material?

I’ve been promised the data to back this up, but I was told that an independent study of the STC (sound transmission class) of fiberglass vs. mineral wool insulation showed that there wasn’t much difference performance difference between the two different materials. Again, I have yet to see the report for myself, but my question is whether this is again a matter of density. In other words, did the testers evaluate batts in the form that we buy them, or did they even the playing field in terms of density, testing the materials themselves, independent of their retail densities.

There’s more to come on this topic, but from the few conversations I had on the show floor, I’m starting to think there will be more to this topic than I first assumed. If anybody has feedback on their experiences with fiberglass vs. mineral wool, please feel free to share!

See all of the coverage from IBS & KBIS

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Reliable Crimp Connectors

Handy Heat Gun

Affordable IR Camera

View Comments

I just insulated my shop with mineral wool, which like Justin, I found to be much easier to install than fiberglass. I don't care whey MW batts are stiffer than FG, just that they are. The stiffness makes the stuff easy to handle and cut (I used our steak knives, whose serrated blades worked great), but it can make installation in smaller cavities a bit harder.

I would say MW is more irritating than FG, but it wasn't a difference that was noticeable when I was wearing long sleeves, gloves, and a mask. Take off the mask though, and I was soon hacking away. Take off the gloves, and I had fibers in my skin. I did not take off the long sleeves.

Would I use it again? In a heartbeat. It's hard to get a good installation with batt insulation, and MW made for the best job I'd ever done.

Did you ever get "the data to back this up"?

^^Bump