Scientists at the Lawrence Berkeley National Laboratory are developing a paint-on window coating that would offer the same energy benefits as a window replacement or commercially applied film at a small fraction of the cost.

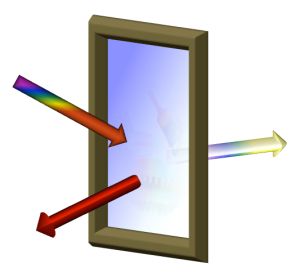

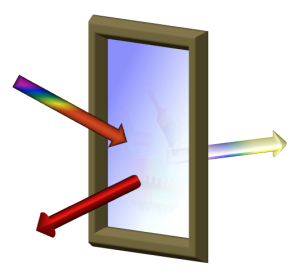

The coating is designed to reflect infrared light but allow visible light to pass through, according to an article posted at the lab’s website.

New windows offer a variety of coatings designed to control both the amount of visible light and solar heat gain passing through window glass, but replacing old windows in order to get those energy-efficiency benefits is expensive. Retrofit window films also are available, but they require professional installation, the lab said.

“Instead of hiring expensive contractors, a homeowner could go to the local hardware store, buy the coating, and paint it on as a DIY retrofit–that’s the vision,” said Berkeley Lab scientist Raymond Weitekamp. “The coating will selectively reflect the infrared solar energy back to the sky while allowing visible light to pass through, which will drastically improve the energy efficiency of windows, particularly in warm climates and southern climates, where a significant fraction of energy usage goes to air conditioning.”

A low-cost option for improving window performance has the potential to save 35 billion kwh of electricity per year, according to the lab, reducing carbon emissions by 24 billion kilograms a year. That’s the same impact as taking 5 million cars off the road.

Program aids entrepreneurial researchers

The technology is based on a type of material called a bottlebrush polymer, which Weitekamp studied as a graduate student at Caltech. He went to the Berkeley Lab last year as part of a program for entrepreneurial researchers called Cyclotron Road with the goal of commercializing the polymers.

The Berkeley project is getting part of a $3.95 million award from the Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E).

The team’s goal is to develop a coating that costs consumers $1.50 per square foot, which the lab says is 10% of the cost for commercially installed retrofit window coatings.

“ARPA-E invests in high-risk, high-reward projects,” said Arman Shehabi, a member of the research team. “The high reward in this project isn’t in the performance improvement. It’s transformative in how windows could be retrofitted-it’s something you can do yourself. The market need is very large, and there’s nothing low-cost out there that meets that need.”

The lab didn’t offer any estimates of when the coating might actually be ready for the commercial market. One remaining challenge is to make a coating that reflects infrared light but doesn’t make the visible light passing through the glass appear hazy.

Read more: http://www.greenbuildingadvisor.com/blogs/dept/green-building-news%2A#ixzz41x0HsKeW

Follow us: @gbadvisor on Twitter | GreenBuildingAdvisor on Facebook

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Handy Heat Gun

Affordable IR Camera

8067 All-Weather Flashing Tape

A paint-on heat-reflective coating for windows under development at the Lawrence Berkeley National Laboratory allows visible llight to pass through while bouncing the infrared portion of the spectrum back.