Visually, the ProHOME’s dormered roofline defines the house. The large gable dormer creates the space for the large master bathroom, while the shed dormer accommodates the other full bath and the laundry room. The low eaves across the front of the house create a horizontal emphasis, reducing the scale of the house and creating a comfortable entry. Maines used the combination of dormer styles to evoke several architectural styles—Victorian, farmhouse, and the venerable Cape—that figure prominently in the local housing stock.

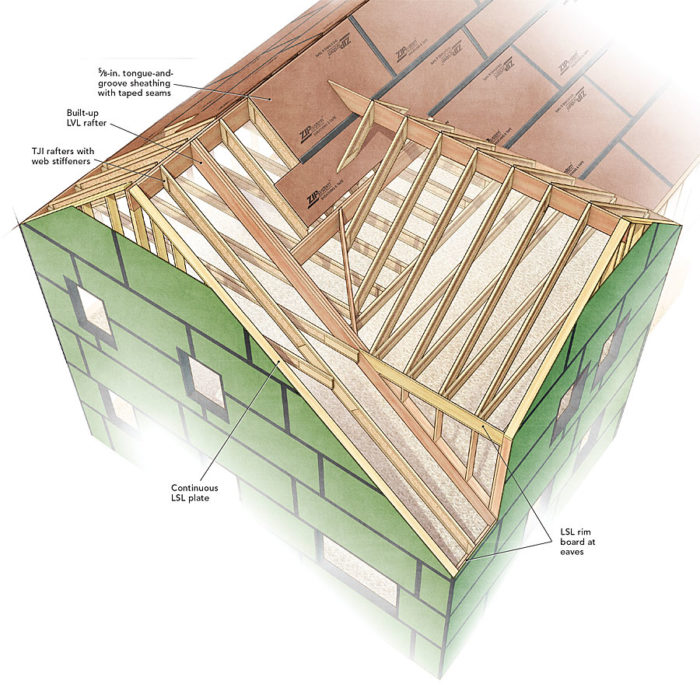

For all its design elegance, however, the roof will be an epic framing job. Guertin figures the second-floor ceiling and roof will take about two-thirds of the framing time for the entire house. The two dormers, each with a different roof pitch, create an irregular valley and add complexity to the framing. Using TJIs for the ceiling joists and rafters takes more time; they are more cumbersome to cut than dimensional lumber, and both the joist and the rafter webs have to be padded out at the eaves so that these offset framing members can be screwed together. Despite the added steps, TJIs have some distinct advantages: They are straight and don’t shrink, twist, or crack—and they’re light, an advantage any carpenter will appreciate.

With a vented roof assembly and a deep blanket of blown-in insulation, insulation baffles are necessary to maintain an airspace along the eaves and at the shed dormer roof. The underside of the I-joists’ top flange is a convenient place for Guertin to fasten insulation baffles that he’ll make from rigid polyisocyanurate insulation. This ensures a clear air path between the continuous Cor-A-Vent soffit and ridge vents. And because of their thin OSB webs, TJIs also have limited thermal bridging compared to dimensional lumber, so they improve thermal performance along the eaves where thermal bridging could occur.

Instead of installing blocking between the rafters at the eaves, a continuous LSL rim board runs along the outer edge of the top plate and braces the rafters and ceiling joists. This configuration is strengthened by connecting each rafter to the stud below with a hurricane tie and by running the second-floor wall sheathing up onto the rim board. The rim board is notched in each rafter bay for ventilation.

Many houses have eaves detailed with a boxed soffit, which is easy to build. But Maines wanted something more appealing. His choice was a traditional-looking sloped soffit that he believes subtly draws attention to the roof plane. Borrowing an assembly method from Passive Houses, he designed the soffit to be built ladder-style and screwed onto the wall through the rain-screen strapping and exterior foam.

The Zip System roof sheathing is an important part of Guertin’s plan to enroll the ProHOME in the Insurance Institute for Business and Home Safety’s Fortified Home program. The Fortified designation indicates that a house meets resiliency standards designed to limit damage from natural events such as hurricanes. The program requires the type of integrated WRB and taped seams on the roof that Zip provides, because felt paper and synthetic underlayment can be damaged when storms blow off shingles. As with the walls, the taped seams get the house dried in quickly and eliminate the need to apply rolls of material on the roof.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Tajima Chalk Rite Chalk Line

Roof Jacks

Plate Level

View Comments

Now You Can Build ANY Shed In A Weekend Even If You've Zero Woodworking Experience!

Start building amazing sheds the easier way with a collection of 12,000 shed plans!

http://www.bestshedplans.info