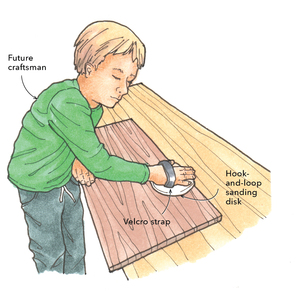

This is a design question. Take a look at the photo. Each masonry column is topped off with a 26x26x 2″ thick cement cap. At the center of this cap is a 8 5/8″ square opening into which a 8.5″ square cedar post will fit. Each post lies on a gravel base, aprox. 3′ below the cap, and extends above the cap another 4′. A 12″ deep gravel base allows for good drainage should water ever enter the masonry column. Each column rests atop a footer, so frost heaving is not an issue. Now comes the technical question.

The masonry column caps are heavy and so are the wall caps between them. I propose to lay the 12″ gravel base within each column first, then install column and wall caps. After this is done, I propose to thread the (treated) cedar posts through the tight cap openings. The posts are plumbed. Now a flexible glue-like caulk is used to seal the tiny gaps between masonry cap and wood column. 8 columns are done in this fashion. Next, these posts are linked to each other with a double 2×8 beam, aprox 4′ above the masonry caps. A 5 foot deep shade structure composed of cedar 2×3’s and 2×6 “rafters rests upon the post-beam framework. It’s not a lot of weight, but decent enough.

My question: Do I need to secure each post to the bottom of each masonry column in order that 1. the post never moves out of plumb and 2. the post can not be lifted up by strong winds? Remember, the 26×26″ masory cap atop each masonry column tightly fits around the cedar post, so there is no movement at that point, safe for seasonal expansion/.contraction. And remember too that the beam above ties the posts one to the other. The lattice shade structure provides additional sturdiness.

I’m asking, because it will be very difficult to raise each 26″ x 26″ masonry cap high enough to pour buckets of rock into the column, to serve as both as “footer” and filler around the cedar post. Each cap has to be laid into a bed of mortat. I suppose it will be much easier to lay all masonry caps into mortar beds, level them, let them dry, and only then proceed with the cedar posts.

I hope the photo below and my word picture above are sufficient to illustrate the point I am trying to make.

Wot thinkst? And…um…can we please avoid joke-ish comments 🙂 Thanks.

Mel

www.froscarpentry.com

Replies

I would want to somehow "pin"

I would want to somehow "pin" the bottom of the post, to keep it from sliding sideways. I don't have any ideas on how to do it, though, given your overall scheme.

It's unclear whether your "shade structure" has any sort of canvas or sheet goods "sheathing". If so, I'd be concerned about uplift and want to do something about that. Less so if it's all open gridwork.

if your just wanting/needing some kind of way of locking the post in place you could pour some concrete in the hole before you set the post.

But in any sort of damp climate it would be risky to set the post in concrete. At most, pour maybe 4" of concrete into the hole, then put a pin (rebar) projecting 4 inches in the bottom of the post, so that the post end rests on the concrete, not in it. And be sure to apply a rot treatment to the post end before placing.

right but the OP says they are not only cedar, but they are also treated. also the water that will get in there will be very limited. plus she has several inches of gravel in there already that will help drain.

one can create a void for draining by placing a 2x4 against the interior masonry wall, pour and before the post is set remove the 2x.

Treated cedar or not, apply rot treatment to the cut end.

Thanks, Mark. You understood me correctly and your idea is well worth considering. I will give thought to drilling a weep hole or two through the masonry column so that any water collecting in the channels (created by the removed 2x4 forms) is drained to the outside of the column. My main concern is that each post is not in direct contact with water (should that ever happen).

To be clear, my posts are cedar. They have been "treated" with a brushed-on sealant, but that means little to me. Once each post is set, it won't see the light of day again. And if my posts don't outlive me (I'm a spry chicken at age 65) I'm gonna be hugely disappointed :)

Others have pointed to the need to "pin" each post to the base material. I see the wisdom of that. I'm scratching my head...and...um...the thought comes to mind that if I make extractable formwork and pour a concrete base, I could insert a square piece of plywood with, say, a 5/8" dia. bolt attached into the column and let it come to rest on top of the wet concrete. This would create a centered hole for the 1/2"" pin that is screwed into the bottom of the post. I'd have to be sure to remove the plywood and the form work before the concrete sets up too much. I worry though that this method may yield a post that is not perfectly plumb, because the pin at the bottom of the post and the cap on top of the masonry pillar (sp?) leave no wiggle room. I'll give this some more thought.

Good stuff guys. I raise a virtual glass of Erdinger Hefeweizen in your direction! :)

Mel

http://www.froscarpentry.com

Another thought. Pour the footer as Mark mentions, and in addition place a 3" PVC pipe in the middle. Pull the pipe along with the form work (see Mark's comments). After the footer dries, reinsert the PVC pipe and pour a small amount of wet mortar into the pipe. Pull the PVC pipe. Now insert the cedar post with 6" of rebar protruding from the bottom center.

I think I got some names confused in my reply above...sigh. A "senior moment" :) Anyways...the shade structure above the posts is "open"; no wind lift to worry about...well, a little bit. The bigger issue simply is wind "push" on the entire structure.

Mel

I thought it fitting to show you the result of our discussion. Here are the posts, snug and tight and ready to bear the load above them; a 6' deep shade structure made of cedar and installed at a slight pitch. I'll try to post a photo when the whole shebang is done. You can view the whole project at http://www.froscarpentry.com

Thanks, everyone, for weighing in.

Mel Fros

So how did you end up handling the butt ends of the posts?

Vell (imagine a Dutch-German, 100% American accent :)...my son eest ze boss and I must obey him...sigh. He ruled out pouring cement cuz of the kalt. Talk about these younglings upstaging their Elders!!! Grrr,,,,Here's what we did:

1. We poured sharp-edged, smallish gravel into each column and tamped. 2. We placed all the wall and column caps in their respective positions. They each weigh quite a bit. 3) With rolling scaffolding to aid us, we climbed on the wall and lifted each 8' post on top (no beer allowed just yet.) Then we needled each post through its cap and plumbed it. Remember, the cut-out in each cap makes for a fairly tight fit, with only 1/16" expansion room on all sides. 3) With the help of Frauchen (wife), we "boys" lifted each colum cap (we made them!) up and she snuck two support bricks underneath. With dust pans in hand we shoveled more gravel into the 2" voids twixt post and MSUs. About a bag per post, which means that aprox 12" of post near the bottom isnow firmly help in place. 4. We lowered the caps back into place and checked for plumb. Everything went perfectly as planned.

You can see the project at http://www.froscarpentry.com

Behave, everyone! (I don't :)

Mel