Well, since we’ve refinanced, we’ve decided it’s time to finally rip out the old patio + steps and replace with a new one.

The current patio is a poorly poured continous slab of rough concrete. Poured up against the brick siding (hence big cracks when that part didn’t settle with the rest) and then later patched with a big spot of asphalt. Beautiful, eh?

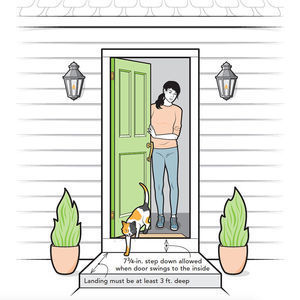

So, what are our options? Our current thought it to take it all out and pour a new patio in the same spot, 4″ deep (we’re in MN) and 6″ above grade to allow for a better look and easier water drainage off and away from the house (as we wouldn’t have the edge of the yard overgrowing and holding water back + we could build a gutter trench in). We’d pour this time with expansion joints, not attached to the brick siding, and with a better (ie bring in the pros) finish.

Are there other practical suggestions? Is it possible to pour an additional 6″ on top of an existing slab? Would cobblestone work as well in terms of water shedding away from the house? If we go with poured slab, any opinions on colored mix vs. staining? Would/should a slab like this have rebar? Mesh? If we pour up to the house, is there anything specific we should use to separate it (I was thinking the usualy board-material they use in expansion joints + masonery caulk on top to seal)?

The only big hurdle now is that we’d probably want/have to bring in a pumper as you can’t get a truck into the area to be poured (hills on both sides).

I’ll try and throw up a picture of the current situation soon.

Replies

Take a look at the Stampcrete website at: http://www.stampcrete.com

Pavers. Good high psi concrete pavers.

You'll never worry about cracks again. No pumper trucks to worry about. All kinds of colors and styles to match the house.

Done right, they're first class.

With the pavers, what kind of watershedding can you get?

We need to get water away from the side of the house. We sit on solid clay, so anything that gets in the current cracks in the concrete goes right down the foundation wall and hits the footer (and then inside our house).

Can pavers, when installed right, with good sand-filled (or other?) joints provide a decent water shed?

I'd much prever pavers (can do it myself over time...no cracks) but worry about the water issue.

It's a function of how well the install is done.

A nice installation will provide all of the runoff you'll need.

Plan your grade accurately. And include drains for the eaves as well as runoff. Done right, you'll love them for a long time.

And search the archieves. There's been a wealth of discussion on these.

Colored concrete is certainly an option. I don't know costs, but I remember the color additive costing more than I expected. Don't try to get by with less dye than the color chart specifies because you can end up turning, for example, sandstone red into pink. Done right, it looks just fine.

Another option is exposed aggregate. This involves choosing a decorative aggregate as a substitute for the standard material in the mix. After just the right amount of setting time, the surface is hosed and brushed aggressively to remove the top 1/8" or so of cement, exposing the tops of the aggregate stones. It leaves a rough or pebbly surface. It can be done with colored concrete.

Pavers, as suggested, can look great. It's a do-it-yourself job, if you're prepared to work muscles you may not be used to working, but you certainly can work an hour or two a night and blow it off if you're not in the mood. You can do all sorts of patterns, colors, designs, and borders. Pavers can weigh 25 lbs per square foot, so your patio can be tons. So, plan well and have the materials delivered within feet of where you need it, spread around your patio.

No matter what option you pick, you'll need a proper base or the patio will move. Concrete will crack and heave all over, and pavers will settle and heave. A good base would be 4 to 6 inches of crusher run stone, 3/4" and smaller. It should be compacted damp with a "jumping jack" tamper-rammer to this final thickness. Allow about 25-35% additional thickness for compaction. That is, 6½" will compact to about 5. Slope the base (and the final surface) about ¼" per foot away from the house.

If you use pavers, install an edging strip made for pavers and cover the compacted stone base with about 1" of stone dust (which is more coarse than sand, perhaps 1/8" or so in size, and rough texture). Don't compact it. Screed the surface dead flat (but not level -- maintain the slope away from the house). Lay the pavers on the stone dust. When they are all layed, compact them into the stone dust with a plate type compactor, beginning at the permiter and working towards the center. Then, spread dry sand on the surface and sweep it into the joints, and compact some more.

With either concrete or pavers you may want to install drain piping underneath to intercept any water that does get through so it doesn't work it's way down the foundation.

I don't know enough to give you a good answer to how much water might work down between pavers vs. concrete.

do not forget acid stain and also stamped concrete. And if concrete is does right not all concrete cracks.

Thanks for the suggestions!

Well, I called today and we're looking at about $100/yard for plain concrete vs. $140+/yard for colored, so yea, it was a bit more expensive to get color than I would have thought, too.

As to your suggestion having the materials nearby, that is the inevitable problem with have no matter which option. The closest we can get to the patio is about 20 ft. up a 3' hill. The patio then wraps around to the front. So, either it's wheelbarrowing patio pavers or it's wheelbarrowing concrete. ;o)

I'm liking the look of cobblestone, but I think I still need a bit of convincing as to it's whater 'shedability'. The main concern is the spring season where you get the freeze/thaw cycles and inevitable periods of puddling water that really wouldn't have any place to go except into the ground. The drain piping is an idea, but we really don't have a way to slope it out to daylight without some serious trenching around the base of the Maple tree (don't want to do that). I figure a well-layed raised concrete patio with the appropriate expansion joints + caulk should do a decent job of keeping the water out of that side of the house.

As for stamped concrete, that is an option too. Probably not something we'd do ourselves, though, so I need to do a bit more shopping around for that.

about $100/yard for plain concrete

Wow, I'm glad I live in Texas (yard of concrete delivered about $50; yard installed with formwork, rebar, and finished, about $1200).

Seriously, all of the options in the thread are really predicated on good prep work. That's things like expansion strips against the house, proper sloping and subgrade work, all done first.

For pavers, in snow country, you will want apretty good pitch away from the structure, around 1/8' per foot. That's not a bad idea for a concrete patio, too--no matter what finish.

Exposed aggregate can be a very nice finish without adding too much to the installation cost. If you do a "brush off," you will probably have to specify water-washed or river aggreate. You can (with the right contractor) apply the exposed aggreate to the screeded and floated slab. (You steel trowel the river rock down into the "cream" raised in the troweling--makes for a very nice finish, and give more control over the finish color.)

Oh, and I can't stand wire mesh in patio slabs. None of the concrete patios I have busted up have ever been stronger for the mesh (when it has been actually in the concrete at all). #3 bar, 18" on center, both ways, is easier to place, easier to work with, and might actually add some strength. But that's personal opinion.

Thanks, Cap'n. We'll definetly have it sloping. If we do the concrete, it'll be a DIY job with the father-in-law (who has past experience as a masonry contractor) helping with the actual pour. I'm now leaning towards the uncolored concrete and adding an acid stain afterword. I'm not a big fan of the exposed aggregate (a bit of a dated look, IMHO) and I'm thinking that'd just be more work anyways ;o)

The tip on the rebar is a good one. Thanks!

You can get a concrete pumper to eliminate the wheebarrowing.

And if you go with the pavers you can rent a compact loader, like the Torro Dingo. Get with the bucket to clean out the existing area and to bring in the gravel for the base and then fork lift tongs to move in the pavers.

Hey Bill.

I'd love to get the pumper, but due to the layout of our property (truck can't get to within 15-20 feet of the house) we'd have to go with the 'big' pumper with a small load (7 yards) so we'd be paying a hefty fee just for the pumper.

Can the Toro handle a 3 foor, 40 degree hill?

Going back to the paver idea...we've been looking at quite a few lately and I do think it'd be a nicer way to go. However, I'm getting mixed advice on how truly 'water sheddable' the pavers are.

So, I had this thought (tell me if I'm crazy): could we leave the slab as is, cover it with plastic (or probably pond liner) and up against the house, and then bring in the crushed limestone + sand + pavers? This would obviously save us the chore of hauling out the old slab and would potentially resolve the water issue. Thoughts on that line of thinking? I'm still leaning towards ripping it out and bringing in the concrete, though just due to the water issue.

Let's put the water infiltration issue to bed.

PROPERLY installed pavers have no water infiltration issue. The tightness of the sand and stone dust packed in between each paver (using the aforementioned plate compactors) leave no room for water to run. Therefore, it simply runs off, requiring the previously mentioned proper grade and drains.

Should some location develop over time that does let water in, fill the gap with more sand and dust and recompact. Try fixing your cracked, dyed concrete that quickly.

Study the proper installation methods and don't even think of introducing your own "engineering" (like leaving the old slab in place and putting the pavers on top). These procedures have been developed specifically to avoid future problems. They are your best bet for success.

Get the old slab out, prepare the bed as suggested, and compact, compact, compact. Compact after the pavers are in place with some sand and dust on top of them - it'll settle in between the bricks, locking them in place and keeping out water. If you screw up anyplace, it'll have something to do with insufficient compacting or grade.

And if you really want to make them look nice, don't whine about how long it takes. Spend the extra time to properly cut the pavers with a diamond bladed saw. And follow a classic pattern (like a herringbone) within a border. Miter both sides of a curving line, not just one. That's how the pro's differentiate themselves from the wannabes.

Select the proper type of paver, with the just perfect blend of color in the pavers.

Personally, I like the pavers that have been tumbled and use a blend of earth tones that match the house and surrounding colors.

If you really want to keep water off, they do have certain silicon sealers that will soak into the pavers and sand, causing any water to bead up and roll off. They are kind of expensive ($50 gal), and some will say they're not necessary.

Pavers will get dirty over time. You can always hose them off, but sometimes the dirt gets in and sticks - not much differently than concrete.

Ever try power washing concrete? End up getting that zebra stripe pattern after? Power washing pavers is no different, and you will blow the sand out of the joints. If you must wash your pavers, I found that hooking up one of those circular power washing heads (has a rapidly rotating wand under the wheeled shield with two or more nozzles) to the power washer does miracles on pavers. Cleans them real fast with much of the sand running back into the cracks (and out of your face). You will want to resand the top of the pavers after, but it should not require recompacting (unless a problem develops).

And if I didn't say this earlier, don't whine about how much time or effort this takes.

!. We don't want to hear it.

2. It takes time for any piece of art to be produced.

3. Do it right the first time by taking the proper amount of time to do it and you will end up saving time over the years in not having to repair cracks and other problems later.

4. Your friends will be amazed about how good it looks. They're going to be asking you questions about how its done. Better to do it right in the first place so you don't have to make an example out of your work on what to avoid doing. And learn to say NO when your buddies want you to help them put in their patios.

Good luck!

"Can the Toro handle a 3 foor, 40 degree hill?"

I really don't know what the specs are, but my guess is that no it can't.

But you are going to handle it with a wheelbarrow either.

Without being there and with my experience limited to what I have done on my property I don't know if this is workable or not. But I would either bring in more materail or use the Dingo to cut down that slope and then restore it at the end of the project.

As far as the concrete pumpe they make different sizes. The guy on the north of me had a concretor that used a small trailer pump. About the size of a large air compressor (the type that you see on road projects). Then the idot that bought the house needed to pour some concrete in the basement and brough in a big truck unit with a boom on it. But they did not use the boom and just hooked up hoses and ran then into the basement.

I don't have any idea of the cost. I suspect that the 2nd unit was not too expensive because it was a POS that leaked oil all over the road and kept jaming the pipe and ended up dumping concrete in my yard.

last time i used a small pumper, it ran be about $550 pumped about 6 yds. 13x17 pad summer starded to set before i finished good think i wasn't going for a "nice" look.

this was about 7 years ago in Ma.

here the truck gives you 30 minutes to offload then starts charging.

wheel barrowing that much concrete up a slope, how long is that going to take?

personally, i'd do the pavers, con on pavers, when i did mine i used stone dust to finish. weeds will eventual grow between the paversbobl Volo Non Voleo

pour concrete, use a front end loader

Thanks again, everyone. Again, a few votes for pavers, a few for concrete ;o)

To clarify, our house sits about 12 feet above street level, so there is no way to get anything up the front. I've attached a photo. The drawback, of course, is that heavy machinery isn't too compatible with our yard.

As the photo shows, our first chore is the retaining wall. We toured a local patio store and I have to admit that the pavers are really the way to go aesthetically with this house. So...we're going to sit on it for a month or so as we finish the retaining wall.

I would seriously look at holding off on that wall.

Take down just enough to carveout a ramp for power equipment. Do the patio and then redo the retaining wall.

BTW, how are you going to do the wall.

I like the idea of the modular concrete wall blocks. Made by the same companies that make the pavers.

Bill:

That front hill is about 8 or 9 feet at a slope of about 45 degrees. There's no way I'd get anything up that. The back hill, that could work...plus it'd be an excuse to resod.

The retaining wall will be your stacked blocks...typical HD or Menards variety. I think we're going to go with Anchor brand ones...either the 4x12s or the 6x16s. The 4x12s are about a 3rd cheaper, so that's probably the option we're going to go with. Probably a tan to match the house.

My brother(the engineer) just finished redoing his patio and deck for just your reason(water running down and pooling next to the house/garage intersection). He opted for the colored/stamped concrete and I think it turned out great(even tho he didn't use ANY curves <g>). I posted a couple of photos on the thread in OTF.

The detail of the colored/stamped concrete is in 4369.18 . Sorry I have no clue how to link.

Life is too short so eat dessert first, especially if it happens to be Cookingmonster's triple cinnamon truffles or her ginger-fig caramels.