Sorry to bother you all with this, you Titans of Timber, you Sultans of Structure, you guys and gals with five-man crews, 20-foot tool trailers, all-terrain telescoping forklifts, seventeen different saws and still counting, but I have a teeny little issue with a teenie little house frame.

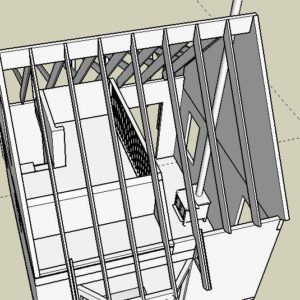

It is the tall gable wall, seen in the pic here. Width is 16/0, height is about 19/5, and the structural ridge requires a small cluster of studs posting down to the floor under it. That pitch is a 14:12, and the break, where the corner meets the rake, is about 10/3 off the floor.

The issue is the height. We can only get studs at 16 feet, max. Period. I did not want to build this as a simple stack, a triangle over a rectangle, with the “hinge” running end to end. It is drawn here as a full-width stack-up, but I don’t like the idea.

What would you do?

Replies

Stagger the joints and build up your post, or rip 'studs' from something longer/wider, such as a SYP 2x12.

Spheramid Enterprises Architectural Woodworks

" If ya plan to face tomorrow, do it soon"

You could get an LVL post that long, no? I know there are mafg studs available but I don't know what length/cost would be. I'm interested in how the pros would do this.Tom

Douglasville, GA

Hi Gene.

I'd frame the wall itself to the bottom of the rafter instead of to the top as you've drawn it. You would then have a gable end rafter that would sit on top of the wall. I don't know if you saw Tim Uhler's article in either last month's JLC or FHB, but that's exactly how I balloon frame gables too. Anyway, I'd still frame it on the deck, but you don't necessarily have to.

I'd then run an intermediate top plate at the 16' mark. Or 12' mark. Or whatever long stud length you'll be using. The top plate would run from rafter belly to rafter belly. Because your rafters are continuous and the plate line would fall in the upper half, you won't have a hinge there.

Sheath continuous to effectively tie the gable rafters to the wall framing. You could also break this top plate on either side of your post if you'd feel better having the post continuous. Stagger joints in 2x or order a PSL post.

I'm sure there's other ways, but I'm pretty sure that's how I would frame it.

Edited 10/2/2006 12:42 pm ET by dieselpig

Thanks for the input, Brian.

Here is the wall, framed to the bottom of the (new) end rafters, and the tall 3-pack in the center is made from max length 16 footers.

It is minimalist framing, 2x4 on 24 centers, and the little shack will be foamed tight with 3" of spray-in in the walls. The little shortie up top is a piece of 4x4.

Seventeen (17!) minutes start to finish with Sketchup, and on another layer, I have all the dimensions shown so this can all be precut and kitted out at the AD&E.

View Image

Where I lived in CA I could buy 2 x 4 material 24' long and 2x6 material 22' long. If you want lumber you may have to order it. Otherwise you could use built up materials.