Hi,

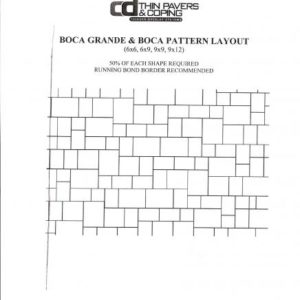

Picked out my pavers for a 400 sqft patio. Saw a pattern at the showroom which I liked so the order was based around that. I have 4 sizes, 6 x 6, 6 x 9, 9 x 9, 12 x 9. Looking at the pattern sheet they gave me and it looks like there’s a couple of no, no’s in it. 4 corners joining at the same spot, long run lines and a single 5th paver size inserted to tie a section together. All in all the pattern sheet looks very adhoc. How can I create another pattern with the same ratio of pavers so I don’t run out of a certain size before the layout gets finished?

Discussion Forum

Discussion Forum

Up Next

Video Shorts

Featured Story

Discover a concrete-free foundation option that doesn't require any digging.

Highlights

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Fine Homebuilding Magazine

- Home Group

- Antique Trader

- Arts & Crafts Homes

- Bank Note Reporter

- Cabin Life

- Cuisine at Home

- Fine Gardening

- Fine Woodworking

- Green Building Advisor

- Garden Gate

- Horticulture

- Keep Craft Alive

- Log Home Living

- Military Trader/Vehicles

- Numismatic News

- Numismaster

- Old Cars Weekly

- Old House Journal

- Period Homes

- Popular Woodworking

- Script

- ShopNotes

- Sports Collectors Digest

- Threads

- Timber Home Living

- Traditional Building

- Woodsmith

- World Coin News

- Writer's Digest

Replies

I dunno. Likes fairly decent to me. The border mentioned is important.

For such areas, I personally prefer a herringbone pattern with a soldier border. But that's opinion and the ease for doing turns.

I'd lay a bunch anyway and then revisit the pattern. I don't think you'll be that disturbed with the results. In fact, you may really like it.

Thanks,

What is a running bond border?

Mike

Lining up either those 6x6's or 6x9's in a row, acting as a border for the patterned "field" inside.

Means you'll have to get more of those if'n your purchase was based upon the percentage on the chart.

What is a running bond border?

A "running bond" is where the bricks or pavers are running parallel but are offset by half a unit.

_/__/__/__/

__/__/__/

k

(no cad program, sorry)

I agree, something doesn't look right.

I'd google paver layout patterns and see what you

come up with.

with the random (not really) size pavers you are talking about don't follow a pattern .. sometimes they all come on the same skid, or the smaller ones on one skid, the larger on another .. soooo, calculate the square footage you need, tell them when you order to ship the correct ratio (they'll no how to calculate), then when they are delivered take a level from the small pallet and a level from the large pallet, that will insure the distribution is random, just avoid laying joints that are continuous across more than 3 stones.

I'm with wane on this one. I build a lot of patios with no pattern. Truly random. I figure how many of each size we have and use them in that ratio. Maybe 5 jumbo, 4 big, 4 med., 3 small, or whatever the ratio is when you divide it out. We call them "pods". The guys hauling pavers bring "pods" to the layer. This way, you don't run out of one size way before the others. Plan on the soldier course border in addition to the body when you order. Bear

Thanks,

I did order a soldier coarse of 4x8 pavers. The ratio of 6x6 to 6x9 is 2 large to 1 small. Same with 9x9 and 12x9, 2 large to 1 small.(delivered) Soooo, I layout my soldier coarse, then I just make sure that for every small paver I put down I will have to put 2 large ones. This seems reversed to me. I would have thought 2 small to one large! The layout plan supplied doesn't pan out either, it says 50% of each pattern but when I count the sizes in the layout it comes out 12x9 =9, 9x9=5, 9x6=18, 6x6=7. (1/2 of the layout) Am I missing something?

Mike

I don't get what they mean by 50% when you have 4 different sizes.

I always order lots of the jumbo so I can break up straight lines in the joints before they get too long.Bear

Yes, I thought that too. I'll call them on Monday and ask about that. The 6x6 and 6x9 are called Boca and the 9x9 and 12x9 are called Boca Grande. I think when you order either one of them, they are already in a ratio of the sizes. You can't get 50 of 6x6 and 10 6x9, for example. So it must mean Boca and Boca grande, equal ratios.

Mike

I don't think it is a soldier course it has to be a sailor course as the largest face is up; if it was a soldier course the strecher side of the paver would be up and I know you are not doing this because the base would be a screwed up

I don't know bud.... I think you are either gonna have to stick with what's on the paper, go random like suggested above, or spend several hours figuring out something else on paper. I don't think anyone here is gonna do the latter for you. The idea is to minimize cuts. Hope you have a good saw...

BTW - how thick are these pavers? Are they made out of a concrete type material?

Attached is a pic of one I did years ago off of one of those pieces of paper like what you have. The pavers were priced each so the masonry supplier let me return the extras.

Thanks,

Thin pavers. I'll just go random.

Mike

Once you get rolling you will start to get the hang of how they best work together in a somewhat random pattern.

Like you I'm surprised by the rato of large to small. That was a great reco someone made about staging "units" in the right ratio so you don't end up with a big pile of one kind at the end (not that I know anything about that...).

View Image

Edited 1/17/2009 6:02 pm by wrudiger

Does the manufacturer have a website with other patterns on it that you like? If you bought the pavers individually, you could always buy extra of one or two sizes to make a different pattern work. You're going to want to keep a few of each around any for future replacements if one gets chipped or cracked. The dealer I worked with on my patio last summer let me buy / return individual pieces as I needed to make things work. I would have liked to have been able to turn pieces 90 degrees but the Unilock style that I chose doesn't allow it because it isn't modular.

Handy thing to do to keep the pattern easy to remember is to use a marker and draw it on a scrap of plywood that you can keep right in front of you and move easily without worrying about tearing it or it blowing away. A sheet of paper with the pattern didn't last through the first night. The plywood made my life real easy.

Staging of the materials is key to making things go quickly and smoothly. The pattern I have took about 12 pavers to complete a 32" square before it began to repeat so I moved enough pavers for 3 or 4 squares to the backyard, laid them, and then did it all over again. Having a second person just to move the pavers would have cut at least a day - probably more off the time it took to lay them.

Thank you so much. A couple of really good tips there. Your work looks great. The pavers are made to order, no returns but they can be rotated.

Mike

we used what is called a muster k pattern on my patio last spring, has a kind of a random look.

Is that column dry stacked?

If it's like the ones I posted above, you use a construction adhesive designed specifically for landscape blocks. PL makes one. Unilock sells one too but it's probably just their label on someone else's product.

Thanks

Yup, what boiler said. 2 thin rows of paver adhesive on each block. The knee walls are locked in pretty tight and only require adhesive on the finish row. The column caps are not glued as their weight is sufficient.