I plan on making a few raised panel doors using the raised panel bit below.

I currently only have two PC 690 routers and Milwaukee 1 1/2hp. I’m guessing none of the above are up to the task? So what “size” router would be appropriate? I’ve been thinking about buying the Festool OF 1400 for a while, would that have enough power?

http://www.festoolusa.com/ProductDetails.aspx?id=4&prodid=574267

Second question, how “safe” are these bits, I’ve only used a shaper in the past and never spun that large of bit in a router.

BTW I realize it needs to be table mounted….

Replies

I'm assuming the O.D. of the bit is over three inches. You should probably use a three HP variable speed so you can slow it down some. The tip speed on a bit that size at 25,000 rpm is pretty impressive as are the forces generated.

A smaller router might drive it but will likely compromise cut quality.

Also check to see if the bit fits through the baseplate centrehole. If not you need to run the entire bit above the baseplate and install a subtable on top of the routertable top. Tough to get the bit securly installed this way too.

Same profile in a vertical configuration works on a 690 at 25K and is much safer to use.

take a look here... this one has the slower (8-21K RPM) speed and soft start..

http://bosch.cpotools.com/routers/all_routers/1619evs-rt.html

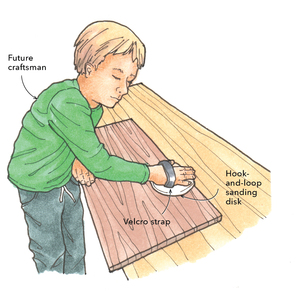

View Image

I sling fair sized CMT's with this one....

Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming

WOW!!! What a Ride!

Forget the primal scream, just ROAR!!!

I run a bit like that in a PC 690 a couple of times a year. It works best if you remove some stock with the table saw first, and take a couple of passes. I also use a speed reducer.

Andy

"Never try to teach a pig to sing. It wastes your time and annoys the pig." Robert A. Heinlein (or maybe Mark Twain)

"Get off your dead #### and on your dying feet." Mom

"Everything not forbidden is compulsory." T.H. White, The Book of Merlin

I was at a semiar by Mark (can't remember his last name, but runs a WW school in IN). He was saying the same thing. The 1 1/2 hp routers (690, etc) are powerful enough. But the advantage of the bigger ones is mass to resist the forces of a heavy cut.

Mark Adams? Nice. Bet that was a good class.Andy

"Never try to teach a pig to sing. It wastes your time and annoys the pig." Robert A. Heinlein (or maybe Mark Twain)

"Get off your dead #### and on your dying feet." Mom

"Everything not forbidden is compulsory." T.H. White, The Book of Merlin

"Mark Adams? "Yes, that is who is was.It was one of the 1/2 day class with the traveling woodworking shows. It covered too many areas, but still lots of good info.

I'd tend to follow Imercs suggestion of the Bosch and Andy's take on removeing some waste with a TS first, depending on the wood.

I prefer a verticle panel raising bit tho'. Less stress on both me and the router bearings. There is nothing quite like the sound of a 3" winged cutter spinning air at 20K rpms....FAAAWOOOOO.

That'll get my attn. faster than a siren and blue lights flashing.

A verticle bit is MUCH safer.

Spheramid Enterprises Architectural Woodworks

I have irriatable Vowel syndrome.

<A verticle bit is MUCH safer.>I can add nothing more.BenGood is the enemy of Excellent. Talent is not necessary for Excellence.

Persistence is necessary for Excellence. And Persistence is a Decision.

<A verticle bit is MUCH safer.>

I can add nothing more.

I can.

Consider the source. Sphere's infamous for home injuries. He's fearless and experienced.

There's a lot to be said for a shaper with stock feeder allowing climb cutting.PAHS Designer/Builder- Bury it!

There's a lot to be said for a shaper with stock feeder allowing climb cutting.

Must be nice....Andy

"Never try to teach a pig to sing. It wastes your time and annoys the pig." Robert A. Heinlein (or maybe Mark Twain)

"Get off your dead #### and on your dying feet." Mom

"Everything not forbidden is compulsory." T.H. White, The Book of Merlin

Of course.

Mine's dual spindle, cost less than a router, older than I am. Does require some real estate (currently unavailable for use). Odd spindles, 1 1/8". Traded a tamper (jumping jack) for the biggest feeder I've seen.

But my best recent find was a (new) variable speed PC router cobbled to a surfacing frame (metal-working). Set up for overarm pin routing, but has x/y handscrews under the table, plus depth-of-cut adjustment both above and below (on the frame, no messing with the router). Looked to me like a mortiser, needing a stock clamp. Already set up with air chip ejector. $175 with some bits?

Yeah, I'll haul it 15 mi. Heavy, ~500lbs.

Ohio, and likely Michigan, is a great place currently to find incredibly cheap large tools. My buddy's picking up CNC in Ohio for at most a dime on the dollar compared to here. He was smart enough to start with a spacious industrial bldg. PAHS Designer/Builder- Bury it!

Ever visit the old woodworking tool website? Fascinating stuff. I keep an eye out for old iron, but haven't had luck.Andy

"Never try to teach a pig to sing. It wastes your time and annoys the pig." Robert A. Heinlein (or maybe Mark Twain)

"Get off your dead #### and on your dying feet." Mom

"Everything not forbidden is compulsory." T.H. White, The Book of Merlin

Ever visit the old woodworking tool website? Fascinating stuff. I keep an eye out for old iron, but haven't had luck.

I'm a long way from a purist. Only interested in what they'll do. Those guys struck me, on my one visit, as collectors (a species I have little respect for). Might have short-changed them, but I don't find these machines particularly interesting until they're chewing wood.

Mostly I've found auctions the place to acquire. Although my pride and joy is an early 40's 36" Silver Mfg. bandsaw, already converted to ball-bearing when I got it from a small metal-working co. It was so nice I bought a power lift truck for the move to Va so I could bring it with us. Truck was a POS that blew an engine in Kansas City, but the lift always worked. I focused on the wrong end.

Seriously, there are a lot of mid-to-large machines collecting dust in the midwest. I've done very well in Va, but those auctions seem to be fewer and fewer. You'd like my 42" 3 drum sander (11,000 lbs) and 24" planer (4500 lbs). Amazingly, both from the 50's and parts still available. Put new springs in the segmented infeed roller when I had it apart. Came with built-in knife grinder. Too large for the hobbyist, too old/slow for production shops = cheap.

That's how I ended up with an old Rockwell 12-14" table saw surplus. One of these days the Unisaw's going to a new home. Rockwell's got a 7.5 hp motor.

Now that I think about it, I've seen large old stuff in your neighborhood (hour or few) on ebay. Too far for me to be interested. I've been looking for an industrial sharpener. Not happy with any of the sharpening services here.

PAHS Designer/Builder- Bury it!

Well, if you ever see an old cabinet saw within 200 miles of CT, you'd do me a favor with an email.

Yeah, I think a lot of those guys are collectors, but I see the attraction in old iron. Not that it's likely I'll ever have the time to restore a tool past funtional, but it's kind of cool that others do. Andy

"Never try to teach a pig to sing. It wastes your time and annoys the pig." Robert A. Heinlein (or maybe Mark Twain)

"Get off your dead #### and on your dying feet." Mom

"Everything not forbidden is compulsory." T.H. White, The Book of Merlin

OK, though I don't spend the time on ebay I once did. Something's changed and it messes up my computer after about 15 minutes, no matter which browser I use. Don't forget to check Craig's list occasionally or better, post on a few.

The best action is auction. And the good ones are always during normal working hrs, so you're going to lose a day. The risk of going home empty-handed I don't mind. Sometimes you find things you didn't know existed, like my mortiser. Other times you end up with a headache, like when I made the only bid on that sander- then had to find somebody to move it. Apparently I overpaid, $50. Moving it was considerably more.

My problem with collectors is not the care they give their tools, but that they create what I consider an artificial shortage, meaning users, as you apparently are, have difficulty finding and paying for functional tools. I much prefer substantial cast iron, pity younger guys who can't find, or pay for, it.

Guy I built a house for here collects non-electric tools, mostly planes. We're "Nahmies" to that ilk, as in that TV guy I don't have the most respect for, users of electric tools. While they have thousands of good tools sitting on shelves, unavailable for anyone actually wanting to use one.

He even told me my favorite hand saw shouldn't be treated the way I do (using it), that it was "collectable". I asked what I might get for it. $60? Yeah, well, I'd rather use it. Nice saw, but the value to a collector had to do with the name stamped on the steel and the configuration of the handle. Cut had nothing to do with it, only scarcity. Yech.

We're still friends, even with his shortcoming <G>. When I was looking for a compass plane way back when, he came over with 3 for me to choose from. Suggested one that had a repair, very nicely done. I happily paid him for it, little value to a collector due to the repair. Cuts like a dream. The other 2 collect dust, probably aren't even sharp.

Soap box relinquished....PAHS Designer/Builder- Bury it!

I do understand your feelings. Although the collectors drive up prices for us users, I don't think there are that many of us. If that's the case, then the collectors serve the purpose of maintaining a market for spare parts and so forth.

FWIW, my Disston D16 sees regular use. Got to get better at sharpening, though. I learned that the way most commercial sharpeners work is to stamp in an entirely new set of teeth each time, which pretty quickly uses up the steel.

And I've got 3 or 4 Stanley #4s, which would make me a collector except that the point is when one dulls, I toss it into the to be sharpened pile and pick up another.

I'm a Craigslist regular, btw. Get a chuckle out of a lot of it. Andy

"Never try to teach a pig to sing. It wastes your time and annoys the pig." Robert A. Heinlein (or maybe Mark Twain)

"Get off your dead #### and on your dying feet." Mom

"Everything not forbidden is compulsory." T.H. White, The Book of Merlin

every body funny, now you funny too.LOL

Really a vert bit is all ya need to stay among the fingered tribe..I have a power feeder that stays dusty...and climb cutting? C'mon, save that for the pros...Niel is like 12 yrs old or something...don't tell him about that..yet.

Spheramid Enterprises Architectural Woodworks

I have irriatable Vowel syndrome.

Yeah, yeah. Don't forget, your reputation precedes you.

I've got a vert. bit too and a 3 hp Makita that lives in the router table on the side of the Unisaw. BTW, a good aftermarket saw fence also makes for a real nice router table fence. But that's a whole lot more cleanup than climb cutting.

I keep telling you, you need a shop.PAHS Designer/Builder- Bury it!

I agree with Andy. If you take light cuts any normal size 1/2" router will turn the big bits. The big router buys you additional depth of cut and overall lower time to finish the project. Fewer cuts also helps your bit last longer between sharpenings.

A speed reducer is a must since it's just not safe to run a big bit at little bit speeds. After having a large roundover turning at full speed break, fly across the room and stick deeply in a sheet of plywood I'm a believer.

For good prices check out http://www.routerbitworld.com or specifically http://routerbitworld.com/product_p/freud%2099-510.htm for the bit you showed.

Beer was created so carpenters wouldn't rule the world.

I've done some work with raised panel bits and have had success with my 2.25hp Bosch router. Piffin suggested full cut but multiple passes. In other words, make three or four passes until you have made it to full depth.

Oh silly me!

Well, that is 2 posts from you without contributing anything.

Not that there's anything wrong with that... <G>

New one on me. Never before heard Mackinac Bridge area residents referred to as trolls. I don't generally get much farther north than Rose City. Or is troll applied to everybody S. of the bridge? But not N. under?

PAHS Designer/Builder- Bury it!

20 miles, eh?

The family summer place is a little S. of Rose City on one of the lakes (Henderson). I generally drive my elderly (95 this year) mother up for her summer. Until they closed the artesian well tap, we'd go to Rose City for drinking water as her well is atrocious. Mandatory stop at the greenhouse. Groceries were there or West Branch. Rifle R. in a canoe's fun. Rose City was her first teaching job, right after the Civil War- as she tells it.

Get her settled, whatever repaired. Spend a couple of days on her tub-sized sail boat and then head to Ohio for Erie serious sailing with a buddy.

Pssst... hate to break it to you, but agreeing with Sphere doesn't always count for much. LMAO

PAHS Designer/Builder- Bury it!

Neil

These panels were raised with a router bit similar to what your showing.

The cabinets are alder, a soft wood, and I single passed them.

My router table is nothing more then a 3 1/2 horse PC (7518 or 19, dont recall)variable speed router mounted to a doubled up piece of particle board with a drop-in insert.

No fancy feeder or shaper. I have a shaper but this profile would have required me to spend the money on shaper cutters that I dont see myself using anytime to soon and the profile was avialble in a Whiteside router bit so I opted for that.

I think there was 35 to 40 raised panels for this kitchen and the router bit did a great job.

Doug

I skimmed the other posts, and maybe somebody has already covered this. For the kind of bit you want to use, the PC 7518 is the standard. The variable speed is a must, since you only want to run a bit that size at 12-15,00 rpm. this machine has been around for years, and is just about bullet-proof. Another option is the relatively new Milwaukee 5625. It has the power (and variable speed) you need, but the nice thing is you can drill a hole through your table and adjust the height with a wrench (provided) on top of the table. I have used the kind of vertical bits that others mentioned, but I don't recommend them. You have to hold your piece very tight to the fence, and it is prone to chatter. I like the horizontal bits because I think the cuts are faster, easier, and more controlled. Imagine trying to hold a door upright against a fence as you make your passes.********************************************************

"It is what we learn after we think we know it all, that counts."

John Wooden 1910-

I have a Delta shaper and two router tables. One table is a portable setup and the other a more permanent deal. I run that same bit on the permanent table with the large Milwaukee 5625 router mounted underneath. I make sure I am on the lowest rpm setting which is 10,000 as I recall. I can't say enough positive about it. I'm sure the larger Festool would be fine. I have the DeWalt 625 for my more mobile setup, and I love it too.

"The nearest thing to eternal life we will ever see on this earth is a governmental program" -Ronald Reagan

One of the Proter Cable routers, the Speedmatic 3 HP I believe, was speshully designed for inverted table mounting.

it has base mounting holes for heavier gauge screws and has a motor with cooling slots that don't fill with shavings when inverted.

But you probably HAVE to spend the 4-5 bills on the festool...

at least 'Cuse lost to a RANKED team :)

"Dogs don't follow an emotional leader. They follow the dominant leader. We are the only species that follows an unstable leader. "

Cesar Millan, The Dog Whisperer, in an interview in National Geographic Magazine

The middle range Festool is 400ish and the largest is 500ish

The reason I want to go with the festool is for use with the guide rail that I already have. I'm not married to the idea of using it for the router table though, I could purchashe the Milwaukee or the Porter Cable for a router table set up and then the smaller festool for use with the guide rail.

More then likely I'm not going to be wanting to remove the router from the table all that often to use it as a hand held.

Neil,

Look at the Triton too. Dont know much about it other than it was designed for RT use. Its about the same price as the milwaukee.

If you buy such a big router you'll probably never use it as a hand held. I use a smaller one for that. 1 1/2 hp.

View Image Official Jeff Buck Memorial Tagline "

Yeah, I'm starting to come to the same conclusion, I already have three 1 1/2hp, but I want the Festool for dado cutting with the guide rail damn it!

so now I needs 2 new routers ;)

guess one can never have to many routers though...

you can try selling the ones you dont use to pay for the ones you will use.

View Image Official Jeff Buck Memorial Tagline "

sell a tool?

you done lost your mind boy.

I just posted to Dieselpig the other day that violates my fifth rule of tool procurement

My goal is to have a router for every bit...

so far it is 4 routers vs ~30 bits

about 15 bits see regular use..."Dogs don't follow an emotional leader. They follow the dominant leader. We are the only species that follows an unstable leader. "

Cesar Millan, The Dog Whisperer, in an interview in National Geographic Magazine

well I recieved an e-mail from woodcraft, PC 1 1/2 hp's on sale for less then a 100 a pop....

how many pennies in your penny jar?

I got the flyer...

saturday only...

DW's B-day...

honey I'd ilke to spend your birhday with you but, I gotta go spend your present $$ on another router(or 2)...

yyyyeaaaaaahhhhhNO!!!!"Dogs don't follow an emotional leader. They follow the dominant leader. We are the only species that follows an unstable leader. "

Cesar Millan, The Dog Whisperer, in an interview in National Geographic Magazine