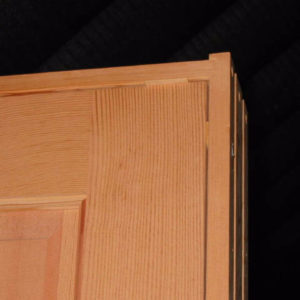

Here’s a couple pics from the door job.

We’re making headway, but after so much repititious(sp) work, it can get a little boring.

I’ve got 20 units ready to go, and almost that many more to go.

I also have to build/match a short(6′), insulated door for the wine room, and mill the mopboard(1200lf). I figure 2-3 weeks.

There’s also some last-minute ‘extras’, like 2 attic scuttle covers made to match the doors.

The job has included some re-production spindle turning, and I also just repaired this pendant from the bottom of the 3rd floor stair landing.

Replies

Are you making the slabs from scratch? How about the frames? Or are you buying components and doing all the assembly (prehanging)?

Door slabs are special order. Kind of odd, but the company only make these doors in 1-3/4" as std. The HO spaecial ordered 1-3/8" for interior. All the hdw. was s.o. also. All jambs&stops are custom made in my shop, because no two walls in the original structure are the same thickness.

And the jambs. All flat with applied stops? i.e., solid select boards, dressed, exposed edges eased with maybe 1/8"R roundovers, hinge and strike prepped, gain or dado for head, etc.?

Are you beveling door edges or did the plant ship them beveled?

I was in the door biz for a dozen years, and have visited 40 or more door shops, from coast to coast, sized from 40 doors per day all the way up to 500.

Have you ever seen a Norfield Magnum machine? It bevels the edge, then machines the slab for the lock, and jigs slab and hinge jamb for simultaneous hinge prep routing, then you apply your hinges, assembled, marrying door slab to hinge jamb, then move it to the Norfield assembly jig, which has a strike jamb machining center on it, and you jig-fit the head and strike jambs in place, staple 'em home, and yell, "next!"

It surprises me that anyone not in the door shop game would take on a project to do what you are doing.

"And the jambs. All flat with applied stops? i.e., solid select boards, dressed, exposed edges eased with maybe 1/8"R roundovers, hinge and strike prepped, gain or dado for head, etc.?"

Yes to all the above.

"It surprises me that anyone not in the door shop game would take on a project to do what you are doing."

I take on the work because I know how to do it, and do it well. My background is from residential construction, and I have been hanging doors for decades. I used to do this on-site, but I work in the shop now because my ankles can't put up with job-site terrain anymore.

I'm definetly not a high production operation, rather, because the shop is well equipped, I can make efficient work from it. I take on practicaly any woodworking operation better suited off-site.