I put down anti fatigue mats in the shop, but didn’t like the way moving around on the soft surface affected my knees (and we couldn’t roll machines around on it), so we laid osb over the whole floor area. Very nice surface to work on now!

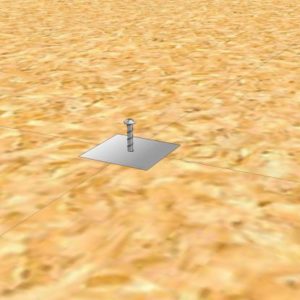

Problem is when the humidity is low the edges curl up. I’m putting in tapcons on the corners but it’s going very slow, and thought I’d save some time by using a small metal plate at the intersections (inlaying it into the osb), and using only one screw for all 4 corners.

Anyone know of a metal plate I can get that is maybe 2″ square x 1/8″ thick or so and has a center hole already punched in it? Thought I’d check here before I go ahead and make my own.

Replies

I've some 3" dia fender washers, from some project..about a 1/4" hole. Shirly you could locate some at McMaster-Carr or such.

These are galvy, I "think" from a simpson post base ancho or somesuch.

edit: hey? A 3" hole saw and a stop sign will yeild ya a pile for cheap.

Spheramid Enterprises Architectural Woodworks

"Welcome to Poo-ville, can I have your socks?

Seriously Folks, I need a home for 3 lovers of your life.

Edited 4/29/2008 6:23 pm ET by Sphere

hhmm, that's a great idea, use some fender washers. I'd still need to countersinhk the hole a bit for the screw head to sit flush. Make a little template to route the circular inset pockets. Good idea!http://www.woodsshop.com

See my edit to add?

A large dia hole saw and stop sign type alum will get a bunch quick..use a drill press and crank em out.Spheramid Enterprises Architectural Woodworks

"Welcome to Poo-ville, can I have your socks?Seriously Folks, I need a home for 3 lovers of your life.

Thought that was a joke!What do you mean by stop sign type alum?http://www.woodsshop.com

Stop signs, detours, curve ahead..all them hiway signs that get munched in wrecks and stuff. I ALWAYS have some laying around the shop..great stuff. Doesn't everyone ?

Don't STEAL them ( esp STOP signs) find a kid that does.Spheramid Enterprises Architectural Woodworks

"Welcome to Poo-ville, can I have your socks?Seriously Folks, I need a home for 3 lovers of your life.

I would go with a large fender washer and rather than routing the recess, use a forstner bit it would be alot easier/quicker

Oh man what a great idea using the forstner!Florida, I'm having a problem because the rubber mat is trapping the drill dust below it, so setting the tapcons is a real problem. I figure drilling one hole, then lifting the osb and matting to clear the one hole one time to set all 4 corners.Great ideas guys! So glad I asked this question!http://www.woodsshop.com

Edited 4/29/2008 9:47 pm by JoeWood

"What do you mean by stop sign type alum?"

I think it means "Why pay for aluminum when stop signs are free?" LOL

I was going to suggest fender washers and a forstner bit but everyone else beat me to it. Seems the best way to go.

--------------------------------------------------------

Cheap Tools at MyToolbox.netSee some of my work at AWorkOfWood.com

Edited 4/30/2008 2:54 am by Ted W.

use a flat head Tapcon...

draw down tite ... no counter sinking required...

Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming<!----><!----><!---->

WOW!!! What a Ride!Forget the primal scream, just ROAR!!!

I have a bucket of metal pieces that would be perfect for your application. They are used for installing the padding under EPDM roofs. We did a job a couple of years ago and had to install the padding. I now have more if exactly what you need then i'll ever use.

Your not in Michigan by any chance are you?

These plates even already have the hole in the middle.

Why not rout a shallow recess at the intersection and let the plate be exposed on top of the mdf. Punch the hole so the screrw hear will countersink flush.

"Put your creed in your deed." Emerson

"When asked if you can do something, tell'em "Why certainly I can", then get busy and find a way to do it." T. Roosevelt

How are you putting Tapcons in that takes so long? You should be able to drill and drive 4 Tapcons in far less time then it would take to let in a metal plate.

Tapcons?

Hilti!! Boom, done, Boom,done etc

You get the picture

Have a good day

CLiffy