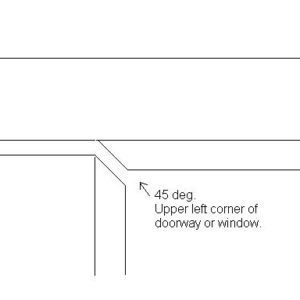

Hi. I’ve got a bunch of casing to hang. As you can see in the attachment, each joint requires 2 cuts on each piece. I drew the sketch with a gap between the pieces to (hopefully) make it easier to see. I’m having trouble getting that little miter joint to fit well.

Does anyone have any tips for getting better results when marking and cutting this type of joint? I’m making the straight cuts with a portable table saw and the miter cuts with a compound miter saw.

Thanks!

Replies

The bottom cut is straightforward. The upper one- you'll probably need to cut the 45 w/ a handsaw and guide, or a chisel with a guide. Or you could build a custom (hand-used) mitre box for this.

If you have a sliding compound miter saw with a depth stop, you can cut that little 45 with little effort. After cutting the straight part on the table saw, just set your depth adjust screw, make a sub-fence (to bring the trim 3-4 inches from the fence) and away you go.

-------------------------------

People are entitled to their own opinions; People are not entitled to their own truth.

Jacob

I made a cherry clock with mortise/tenon doors with this detail. First, setup the table saw to cut just up to the bead miter IIRC, I actually cut these with the edge on the table, running it through multiple times, leaving just enough material to clean up with a chisel.) Then I constructed a jig so the rails/stiles (or casing) fit snuggly sandwiched between two pieces of hardwood mitered to 45 degrees. With the rails-stiles/casing clamped in place, I used a wide, very sharp chisel resting on the hardwood jig to pare the miters until they fit right. I only had two doors, however, and the clock was a Christmas present for my wife. In a business/production setting, depending on the number you have to do, you might want to try a faster method.

You could probably miter the casing bead, then rip the excess on the table saw. The jig would still come in handy to clean up the cut to get a tight joint.

"I am the master of my fate, I am the captain of my soul." Invictus, by Henley.

Thanks for the advice. Unfortunately, I don't have a sliding compound miter saw, just a regular one, so the depth stop is not available. However, Nick's suggestion of a "sandwich" jig got me thinking. Using a couple of pieces of scrap molding, I made the jig you can see in the attachments. It's attached to the fence of the saw with double sided carpet tape (love that stuff!)

It works pretty well, as long as I perfectly cut the total length of the piece. If I cut too short or too long, the miter ends up offset one way or the other, of course. Then I have to trim a little, try again, trim a little, try again... etc.

Look at Gary Katz's web page, there is an article there on doing what are called Jack-miters. Pretty close to what I think you are doing.

web page: http://www.garymkatz.com/TrimTechniques/Jack-MiterJig.htm

I like the sandwich jig idea to though. Im actually going to be doing some trim like this for the first time tomorrow.

-m2akitaLive by the sword, die by the sword....but choose your sword wisely.

Why don't you just do this with a 2 piece build-up?

Matt, I'm doing it this way because that's how it's done in the rest of the house. This new stuff is going in an addition. But what did you have in mind? Did you mean use a 1x3 and then a separate piece for the small ogee part?

M2 - that's an interesting link. I may consider trying to screw the whole thing together before I hang it and see how that works.

Another question: what's the best way to deal with a door jamb that isn't flush with the wall, but is inset a little bit? That really screws up the angle. Would you plane some off the back of the casing? Shim out the door jamb?

If you think of the way a swoop miter is done at the end of a stair tread, you can make a nifty router jig that will handle the jack miter detail, but you need to compromise and have the long straight part of the mating surfaces offset from the cockbead line.

It can be done for ells and tees. Made with good jigs, the joints are hairline, and if snugged with pocket screws, become just about invisible if the work is painted.

I have attached a pic of what the joint looks like when made thus. The scale shows moldings 3-1/2" in width, with the edge beads 1/2" wide. The circle in the pic depicts a 3/8" diameter router bit. See how the horizontal mating joint needs to rise because of the fillet the router makes in the corner?

Cutting back the wall under the casing will get the edge to seat down on the jamb, but there may be an issue with the out-of-plane rock the casing will take, if the wall is quite proud of the frame face.

>> I'm doing it this way because that's how it's done in the rest of the house. <<

Is it really? Must be a pretty old house. Generally, modern trim techniques would pretty much preclude that kind of joinery unless it's at least close to a million dollar house. Remodelers might do that kind of thing, but then again, the price of some of their additions is easily the same or more than a complete entry level house would cost.

I do think you should match the rest of the house though, but still think even if the original is done like you are proposing, the new stuff could be a very close replica with a 2 piece buildup. Having a 2 pc also helps you to compensate for discrepancies between the wall plane and the edge of the door/window jambs.

>> Did you mean use a 1x3 and then a separate piece for the small ogee part? <<

Yes

>> Another question: what's the best way to deal with a door jamb that isn't flush with the wall, but is inset a little bit? <<

To add to what stinger said, trim carps deal with this every day. First plans of attack are to a) nail the sheetrock tight to the framing with roofing nails. These are placed such that they will be hidden by the casing. b) the first 1" of so of the drywall can literally be beaten into submission with a hammer, although "tapped" might be a little better word.

Edited 12/15/2005 6:11 am ET by Matt

It's definitely not a million dollar house, but it was built in 1935.

And I think I will be "tapping" down the sheet rock in places.

After struggling to get a perfect joint the other day, I took a closer look at some of the joints on the "old" stuff. After 70 yrs of settling and so on, they aren't perfect either (of course, they may not have been perfect when installed originally). Maybe I should not worry about it so much, and also put 10 coats of paint on it, and it will really look authentic ;-)

A little caulking and paint make the carpenter what he aint! :-)

We call it rock bashing. Or ripping. The thing I dislike most about it is the mess it makes on the floors.

I keep promising myself, but I always forget. Next house I build I will run around for one whole afternoon with a power plane, and thin down all opening perimeters.

Seems like maybe factory applied jambs (windows and doors) should be 4 5/8 rather than 4 9/16s (assuming 2x4 walls). As far as the mess - get a cleaning person :-) - I LOVE my cleaning people.

Rip the straight piece first. Layout and cut the miters with a small handsaw, a backsaw works good.Place the head and jamb pieces on horses.Clamp to the horses so you can run the back saw thru the miter for a perfect cut. This method of cutting the jackmiters will shorten the distance between the legs slightly,allow for it .Biscuits or pocket screws on the back side will hold it together on thebench.Then you can install it as a unit.

mike

table saw and a miter guage.

the overcut is on the back side and hidden .. never to be seen again.

I took a look at the Gary Katz link ... I'd simply run that thru the table saw standing up ... with the blade set at a 45 and at the right height ... kiss the bottom ... and clean out the corner with 2 swipes of a sharp utility knife or a light touch with a sharp chisel. What am I missing here?

Now that I think about it ... the original poster cut could also be chopped at the compound mitersaw by tilting the stock forward a bit. Just cut to the line ... again ... overcut is on the back ...

Jeff

Buck Construction

Artistry In Carpentry

Pittsburgh Pa