I’m planning to build a 4’x8′ concrete form for raised bed gardening.

I’m thinking of making it about 3′ high with slightly tapered sides (inside and out)to facilitate lifting the form off in one piece for re-use. I’ll lift and move it with a loader.

EDITED TO ADD: I’m thinking of an inside form and an outside form to make the final product around six inches wide at the bottom and sour inches wide at the top, thus allowing a one inch taper (for each side) over the three feet height of the form. Hope that makes sense.

What I’m wondering is how to make the form panels as slick as possible.

If I use 1/2″ AC ply for the form (with 2x reinforcement) could I just use motor oil on the form material to get it to let go? I’m not fond of this option, but it would be cheap.

Would it make a difference in how well it lets go if I ran the grain vertically (horizontally would be easier to build).

Do you think that 1/2″ ply will be strong enough or should I go with 3/4″ even though it will add to the cost and to the weight of the form?

What if I coated the inside of the form with urethane? Would that be “slicker”?

Would CD ply work? Or would the likely knot holes be a problem when it’s time to lift the form off the concrete?

This is a garden project, so I’m trying to keep the cost as low as possible. The finished product doesn’t have to be beautiful and if it’s too ugly I could parge it.

All suggestions welcome!

Thanks.

Edited 10/22/2009 6:56 pm by husbandman

Replies

To make form easier to remove: 1) use "form oil" , sprayed on the face of the forms. This keeps the concrete from sticking to the forms. 2) Be a little patient. Let the concrete "set up" enough to allow the forms to come off. 3) IF you can find some, use MDO, as the paper face (well form-oiled) doesn't stick to concrete.

Thickness of plywood: 1/2" will work IF well braced. Otherwise, use 3/4" ply. Grain direction only matters in the grain pattern you want to see left on the finished concrete. You could always sand the face before the first pour, but after that you'll just have to scrape it smooth. Make sure that there are no defects in the form's face. Concrete has a way of attaching to defects and making them worse.

Thanks for your input.I was trying to get away from spraying the oil since I don't have the right sprayer. Also wondering if I'd have to buy more than I'd need and wondering if form oil would not be good for a veggie bed???In the 70s I was taught to use USED motor oil on forms (by a crusty contractor I worked for). At least I know I won't do that!I had thought that perhaps having the grain on the ply vertical might help it break free when lifted off. It may be worth it for me to buy the best materials since I hope to use the thing repeatedly.

Wrap your forms with visqueen. Makes a really smooth surface on the 'crete.KK

That could be a big help.The look of the outside isn't terribly important, but the lift off of the form is.

Like coonass stated visqueen does wonders.

We have spring loaded floating concrete floors on our current job 2 layers of visqueen was used for the release agent.

If you want an exposed aggregate look on the outside you can coat the form with a well mixed 70/30 corn syrup/sugar mix that will prevent the concrete from setting.

Hose down after pulling the form & viola exposed aggregate.

Corn syrup/sugar...That's a great tip!

sugar retards the set. i found out the hard way. when i was wet behind the ear and didn't know better, i was troweling a garage floor. i had a coke with me and spilt it on the floor. i didn't think anything about it and troweled it in. bid mistake, went back the next and a that area was still soft. for all i know it still may be soft.

I know, it's like cooking sort of, sugar slows the mud down and salt speeds it up.

form oil is a modified mineral oil, should have problems in veggie bed. your not going to use that much any how. if you don't have a sprayer, use a paint brush or a paint roller. i wouldn't worry about the grain of the ply. the concrete will shrink enough to make it easy to pull the forms, as long as you oil them.

For garden projects like this I've used canola oil with fine results.

That was my hesitation with any typical product.

I think it will be impossible to lift unless you have a bmf backhoe. If it was me, I would build it 3 inches instead of 3'. Seems kinda thick for the intended use :) or am I misunderstanding your intent. You are talking about a pad, right?

No. Sorry I didn't describe it better.I'm talking about a hollow box sort of thing made of cast in place concrete. The inside of the box would become a raised bed for veggie growing.The form would have two major parts: the inside and the outside.I wouldn't lift concrete, just the form off it.

around here we call that a "rock form", use the highest grade 3/4" plywood you can afford (don't use 1/2" you will get "pillowing" (this is were the plywood bows between the braces)). i use epoxy coated 3/4" plywood when appearance matters, but epoxy plywood is big buck. form oil is the best, but if you can't find it or don't want to pay for it you can use a vegetable oil. don't use motor oil, it can stain the concrete. build your forms with 2x4's, top and bottom plate, and uprights 16" oc. if you want to save weight, build your form 2" taller then you pour. i don't understand why you want to lift the form off, we pry them off the wall. are you using ties in you'r wall, or are you bracing from both sides? how thick is your wall?

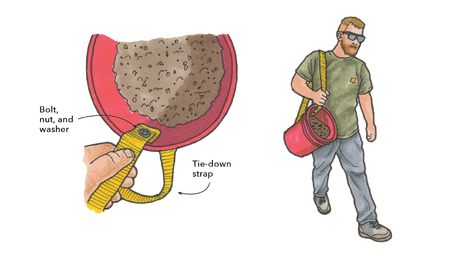

I'm thinking something like a big concrete box. The form would be both inside and outside of said box. If I could lift it strait up I could leave the form intact and simply move it to the next spot and be ready to pour again.

Unless you are dead set on building forms I have another method.. Use 6" "Lintel blocks" level out the ground where you want them and dry stack the blocks 2 block high , drop a piece of 3/8 or 1/2 bar into the knock outs and fill the cores with sack mix.

I have some here that I did almost 20 years ago and they are just fine. Life is Good

Edited 10/22/2009 7:37 pm by dovetail97128

I've thought about something similar, but then I have to buy the block and the concrete (less, of course) and I have the look of block instead of the look of poured concrete (my preference). Plus it would be thicker.Hmmm.Making me think again. <G>

Couldn't you make the form on the inside and the outside separate?

On the top of the form you could span the two with a 2 x 4 and screws.

At the bottom use some strong wire to keep it from spreading.

When you go to take off the forms you unscrew the top and cut the wires on the bottom.

It will make taking it off much easier and it will weigh half as much. Well if carry them separately. ; ^ )

I'd make a few of the corners easy to take apart as well. Especially the inside ones. Just use a lot of Piffin screws ; ^ )

Will Rogers

Good thought, wheelie!I was thinking that I wouldn't need to have the inside and outside forms come apart, but now I can't think of any good reason that they couldn't. I think my skid steer loader is rated to lift about 1400 pounds... not that much (small machine), but if inside and outside are both tapered it seems like it would come off pretty well.I was thinking of gluing all members together with PL Premium (to make up for the #6 rock screws, of course) <G>Hmmmm

inside corners are always hard to take apart. use a piece of 1/2 expansion between the two forms. makes it easier to take apart.

I agree.

From my little experience with forms and concrete even if there is a little part of the form trapped inside two parts of concrete it is a pain in the rear to get it apart.

It can be pretty frustrating.

"There are three kinds of men: The one that learns by reading, the few who learn by observation and the rest of them have to pee on the electric fence for themselves."Will Rogers

For forms, look at phenolic coated plywood. 3/4" thickness makes it stiff enough for what you are going to do, provided you add some ribs for support.

Check with Whitecap. They can order it for you if it isn't available in their yard. I bought a couple sheets earlier this year for around $50 per sheet.

May seem expensive versus 1/2" ply, but the pheniloc coating helps with form removal if properly coated with a form release agent. And compared to the cost of 3/4" ply, it really isn't that much more.

I think I can say, and say with pride that we have some legislatures that bring higher prices than any in the world. - Mark Twain

we use a chinese plywood that cheap, it doesnt hold up good, but cheap.