Hi all,

I’m having a bit of trouble understanding the code requirements for headers under rim joists under IRC 2018. To summarize, does the rim joist that runs parallel to the floor joists itself count as a header for a window opening made of CMU’s below?

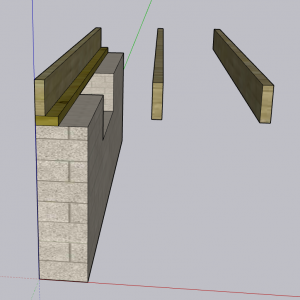

I’ve drawn a quick sketch, attached below, to demonstrate the problem. This setup would allow for a larger window, which I would prefer.

The floor joists run directly parallel to exterior bearing wall where the window would go. I understand how to size the header based on the prescriptive tables otherwise. Assuming this is a ‘roof, ceiling, one center bearing floor setup’.

The basement walls are made of CMU’s from bottom to top, rim joist on a single sill plate, no wood framing below the rim joist.

The rim joist is continuous and adequately sized (if it were a header) for the span per table R602.7 (1).

Rim board headers are referenced in R602.7.2R602.7.2

Rim board header size, material and span shall be in accordance with Table R602.7(1). Rim board headers shall be constructed in accordance with Figure R602.7.2 and shall be supported at each end by full-height studs. The number of full-height studs at each end shall be not less than the number of studs displaced by half of the header span based on the maximum stud spacing in accordance with Table R602.3(5). Rim board headers supporting concentrated loads shall be designed in accordance with accepted engineering practice.

If it CAN be used as a header, are the jack studs necessary given that it already rests directly on the foundation on each side of the span? I can’t find much in the IRC to clarify regarding rim joists on foundation walls, only for wood framing.

Replies

You can build the header in the floor as you’re considering. You will not find info in wall construction section of building code b/c when the header is in the floor it is considered a girder (although we all usually refer to it as a header). You will need to refer to the floor construction section. You will find bearing requirements etc in that section.

With your girder running parallel to the joists the argument can be made that it is not carrying first floor load (an argument that my inspectors have agreed with me on), so you do not need to include first floor load in determining your girder size, unless your inspectors view it differently. Depending upon the size of your opening you may discover that a single ply header meets the requirements and you may not be required to double (or triple and so on) the girder.

im exploring the same problem right now. the rim joist is correct like the other guy said if doubled. problem is on a 16in center your floor joist is probably going to land on top of the window somewhere. the sill plate WILL sag at some point just from pressure on the floor joist. not a good situation for opening a window or cracked glass.

Thank you for the input! I neglected to mention this is existing construction- which complicates things I suppose. The opening in the CMU's is existing and just boarded up- why the previous owner did this is anyone's guess, structurally it's exactly as I showed before.

Regarding the no floor load- that makes sense to me- i'll check with my building inspector to see his opinion on it. If so, the existing rim board should be sufficient based on the span tables if I understand your post correctly.

About the sagging, yeah, i'd rather make it a bit stronger to avoid that but I'm just going to do vinyl windows since it's a workshop environment, but possibly upgrade them in the future.

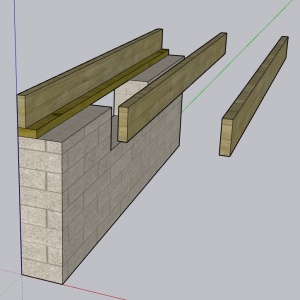

I made a few additions to clarify the situation- the subfloor is directly above the joists in the picture, and I added what I would like some input on if you would kindly offer it.

If the header/girder needs to be doubled for the span, is the doubled header I put in the sketch the acceptable way to do it in a situation like this? I'm finding it hard to find examples of 'two piece' headers where one board is longer than the other, and if that even counts as doubled up. Worst case I can add another small sill adjacent to the existing one and put two equal length headers (so total 2 new boards sandwiched, 1 existing rim board vs 1 new board 1 existing rim)

Jacking the house up slightly around it is no problem to get the header in.

Thanks!

Yes, as drawn is exactly what I have done in the past. I’ve always installed perpendicular blocking as well to help keep the girder from wanting to tip under load and it helps tie the rim into the floor joists structure too. I don’t know if the blocking is required by code, but I never really researched that as it’s just something I like to do and it has passed inspections before.

The rim joist does function as 1 ply in the girder. Small windows and crawlspace vents often do not require doubling up as 1ply will take the load, so you often only see rim with no doubler in that situation. The rim is acting as a single ply header.

that short one helped a lot. good luck!

In my current reno, the rim board is one ply of the lintel over the windows (6' opening and a 2' opening). There are no jacks. The second ply needs to have adequate bearing on the concrete, I allowed 2.5" at each end and my inspector had no problem with it. In my case, the floor joists were perpendicular, and so had to be hung from the inboard ply of the lintel with joist hangers.

How did you get the second ply into position with the perpendicular joists? I have to do something similar soon and have been trying to figure out how that can be done from inside.

You can cut the joists back 1 1/2 inches to prep them to hang (after supporting with a temporary wall of course) but I am having a hard time picturing getting that second ply in position.

gstock88 - Builders' Lament: I can't build what you drew. Designers' Response: Don't worry about feasibility, just do it.

Note one comment referenced minimal 1 1/2' or so bearing at either end. In fact it is unnecessary since the shear capacity of the member is 2 or 3 times the bending stresses at the middle. Scabbing a plate to the center 1/3rd correctly addressees the bending stress...

Another approach to install a sister-rim-joist might be to reduce the height at the ends (a top diagonal cut, perhaps just at one end; or a bottom flat cut with angled transition, such that you have a reasonable working length , and then add plate height accordingly.

But in the case of not widening the the existing opening, there is no impact if you remove foundation wall below it as long as it does not compromise the immediately adjacent wall.

Much more interesting to me is the upward enlargement of such a window in a foundation wall parallel to the floor joists, and the use of a steel lintel at the top of the rim joist, and remove the rim joist within that envelope. This raises the window sill (addressed with a step or two in the basement, ) and reduces the depth of the egress hole, making the entire contraption a little safer.