Roof Design and Sheer Forces on Unvented Roof with Exterior Rigid Insulation

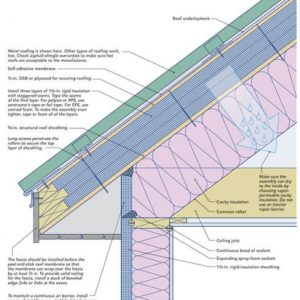

Hello, I have a question about sheer forces in the unvented roof assembly described by Martin Holladay in this FHB article from 2011. The cross section from the article is shown below. A similar design appears on “Cold Climates” book by Lstiburek.

Are the beveled 2x4s shown at the eaves the only bracing to counter sheer forces created by the weight of roofing materials and snow? Would anyone have concerns that the top sheet of plywood would sheer off the assembly?

How can such an assembly be re-inforced without creating thermal bridges that undermine it?

Thank you,

Jon

Replies

perfectly good detail

JonJaroker wrote:

Hello, I have a question about sheer forces in the unvented roof assembly described by Martin Holladay in this FHB article from 2011. The cross section from the article is shown below. A similar design appears on "Cold Climates" book by Lstiburek.

Are the beveled 2x4s shown at the eaves the only bracing to counter sheer forces created by the weight of roofing materials and snow? Would anyone have concerns that the top sheet of plywood would sheer off the assembly?

How can such an assembly be re-inforced without creating thermal bridges that undermine it?

1. Are the beveled 2x4s shown at the eaves the only bracing to counter sheer forces created by the weight of roofing materials and snow?

No. As the drawing says, they there to provide solid nailing for the fascia.

2. Would anyone have concerns that the top sheet of plywood would sheer off the assembly?

I wouldn't. However, someone like Mark122 that doesn't understand buidling or structure might.

3. How can such an assembly be re-inforced without creating thermal bridges that undermine it?

It doesn't need to be reinforced...and the detail has fully resolved the issue of thermal bridging.

In his typical condenscending reply, NUMBNUTS provides his also typical worthless answer.

The upper sheating in the assembly is secured to the lower sheating and the rafters (which are indicated by a callout but not shown) via the long screws. This isn't a different version of a SIPS panel. It is a conventionally framed roof (stick or truss) to which insulation has been added on top of the traditional structure which is then covered by additional sheating and then roofing. The long screws depicted are probably the only detail you missed (along with them not showing the rafters so they could show the additional infill insulation between the rafters).

To complete the question, we need to know which screw, how often, and how much penetration into the rafters. A nailing pattern for the first decking would be helpful also, some may assume the top layer will secure the bottom. Proof that an engineer's drawing is only as good as the person reading it. I know it is to illustrate the insulation detail, but not all viewers do. If this were the only section to tell me how this building is done, I would have a page of questions.

Shear transfer.

I don't see any problem with the two layers. The bottom sheathing is enough of a diaphram, but I don't see how the shear is being transfered to the walls below. The diagram doesn't seem to show any shear paneling on the walls and it looks like a single top plate. Code would require blocking at each rafter bay and a clip connecting it to the top plate. Thermal bridging would be minimal since the block would be outside the rafter insulation and there is already a bridge at the top plate. Another detail missing is support for the soffit.

It's an illustration

I believe the drawing is an illustration meant for focusing on a important details for a continuous thermal envevlope. It doesn't address wall bracing. It doesn't address transferring shear forces from the roof to the walls. It doesn't address siding. It doesn't address exterior trim details. It doesn't adress interior trim finishes. It doesn't show alot of things. That's because it is not a working drawing and it doesn't have to.

The question from the O.P. was if anyone had a concern that the top layer of plywood would shear off the assembly. I addressed the question. For the usual strange reasons, some particularly incompetent regulars seem bored with their lives and choose to address everything but.

Forum

A meeting or assembly for the open discussion of subjects of public interest.

It was all relevant except your personal attacks.

Apparently you are suffering from localized amnesia. Either that or your reading comprehension is seriously challenged.

I hope it is the latter, as it would at least make you appear innocuous.

Dead nuts, apparently you are suffering from Megalomania. You are getting tiring, but I know you have heard that before.

I'll again suggest that you make use of the "IGNORE USER" button.

Personally

I'd like to run into the genius someplace.

talk's cheap

Why wait for serendipity? Call me to arrange for this to happen.

You can say that again.

This years fest, August.

Okay. Talk's cheap.

I guess you don't want to run into me as much as you'd like others to think you would.

What?

Fest in August, Ft. Wayne, Indiana.

not soon enough?

be in Burnsville, N.C. tomorrow. Wednesday Charlotte. Friday its Beaufort, S.C.

the way home only takes us through the west end of Virginia the following week.

you seem to be anticipating an ass whooping, why so confrontational?

.

I'm not anticipating anything. I'm in Fairfax, VA. You're welcome to visit me anytime you like.

Hahaha

Hey Calvin, hows that golf game doing? next trip around these parts swing by and Ill show you how much my golf game improves as my 5th of whishkey fades quicker than my drives....

deadnuts,

You really don't want to mess with Calvin! Hells Angels have been known to walk away with their tails between their legs after talking to him, Crips and Bloods have been known to pull up their pants after meeting him. Just because of how nice he is. If that doesn't work and you're still an AH he will show your boyfriend his pecker. He ain't known as Big Cal for nothing!

KK

its like watching a bad accident, you want to turn away but just cant seem to be able to...

Well, then I wouldn't know

Well, then I wouldn't know why so many people are pissed off at him.

OK, I am now accepting your advice. Certain people here do not need to be paid attention to.

Additional information and Thanks

Hello cussnu2, MYBuilder and Mike Mahan,

Thank you for your intelligent response to my question.

Upon further researching the HEADLOK screw types from FastenMaster, I found the technical sheer strength data and fastener spacing for different cladding weights and stud spacing. (This is in Table 2 of their Technical Evaluation Report titled, Use of FastenMaster HeadLOKTM Fasteners to Attach Cladding and/or Furring to Wood Framing through Foam Sheathing.)

The roof pitch I will be building is 12-12, so half the weight of the roof shingles would be a sheer foce. The fastener spacing would be either 24" or 16" on center. I think the HEADLOK screws must penetrate 2" into the rafters.

Mike Mahan: I'm not sure I understand your comment about code-required blocking at each rafter bay. How would that be constructed? Do you mean securing the panels at their seams through a clip?

Regards,

Jon

Construction Blog: http://37lincoln.com/roof-assembly/

How

When I look at this assembly, I always wonder how to accomplish it safely then think, "Isn't it easier to accomplish under the roof?". I don't like to wrangle plywood in the wind, I can't imagine three layers of foam. I understand the concept, but SIPS seems easier to me. As for the blocking, in my area the blocking needs to be between the rafters to keep them from rolling, especially if the roof is common straight through with no valleys or hips.

SIPS IS DIFFERENT

Sips is different than dealing with the insulation under the roof. I wasn't clear on that.

YOu probably can't imagine it because you've probably never done it. We have. I can assure you that it didn't involve any wrangling and surprisingly enough, we lived to tell about it.

You probably CAN imagine.

I think you've wasted a lot of time by not answering the OP with the relevant information a seasoned veteran could have offered. That is, instead of restating the question, pointing out the obvious, downgrading others posts, and condescending one word replies, just tell the info you know. If you do.

You are making an [JOBSITE

You are making an ass out of yourself again by assuming you know anything about MYbuilders knowledge. And once again you prove that you have a reading disability.

And who is this we? You and your other you? Or your boss and yourself?

I wish you'd either grow up or go away.

If you think you'l lose sleep over this detail (not intended as an insult, just thought I'd mention it based on the lunacy of the replies) then run a few metal straps over the top of the ridge. Screw the strap into the roof sheathing on one side. run the strap across the ridge and bend it down. Then screw the other half of the strap into the sheathing on the other side.

Something along the lines of a simpson flat strap. Nor recommending this one in particular, it's simply the first hit I got:

View Image

Nothing wrong with a warm fuzzy.

But as you've discovered, the screw manufacturers usually have fastener schedules based on the slope of the installation and the thickness of the insulation. A few other factors can come into play too. For walls, stud spacing comes into play too.

Regardless, good luck.