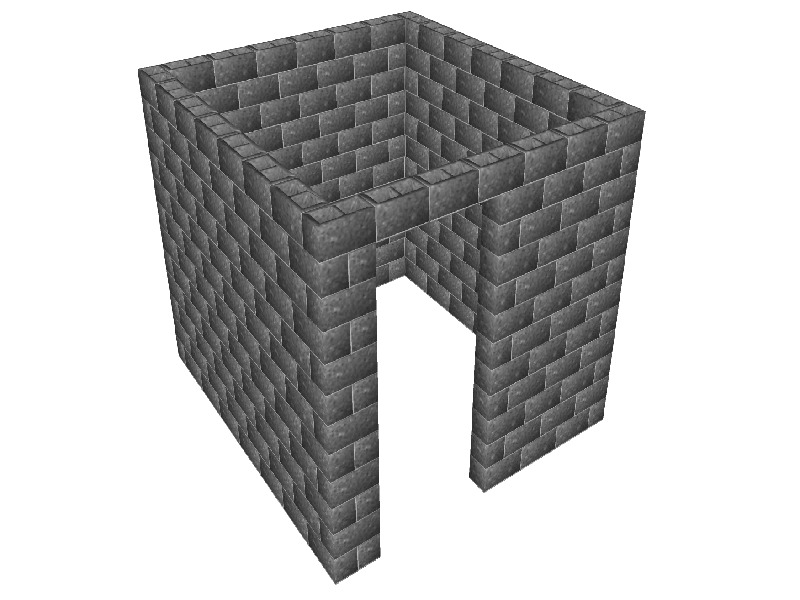

Roof Slab for Concrete Block Cold/Safe Room

I’m designing/planning/dreaming of building a coldroom that can double as a saferoom. (See beginning drawing.) I started with a FEMA / Texas Tech design.

It is concrete block construction on a much larger concrete foundation (with allowances for the added weight of the room.)

It will be freestanding and not attached to anything except the foundation below. This room will be inside of another building so weather is not really involved.

There will be only one opening for a steel door.

The inside dimension as drawn is 8 ft. x 8 ft. x 8 ft. Of course, that could change by a block width either way.

My problem is that I’m not sure about the ceiling roof slab.

I was angling for putting pan deck (AKA: Steel form deck) up on the top layer, building a form and pouring concrete in place. With necessary rebar of course.

I would like to pour into at least some of the openings in the top course of blocks to anchor the top to the walls.

There doesn’t see to be a good way to anchor the pan deck before the pour, and I’m not sure how much support I need below during the pour (although I’m sure I could over do it considerably.)

I’ll be glad to post the final plans if I can get some experienced advice. Thanks in advance!

EDIT: Changed from “ceiling” to roof slab for clarity.

Replies

where I have done that, we just had a forrest of studs cut to the right length to wedge in as supports about every 16" or less while pouring

This is similar to the way they do a stem wall floor in Florida. The top course of block will be "lintel" block, a block with a 4x4 notch in one side. This is the ledge that holds the deck/roof. Drop in steel decking and pour your concrete.

As for the steel, put 2 #5s continuous in the footing. Tie hooks (rebar with a leg bent in one end) to the foundation steel sticking up that you drop the block over. You want a "dowelled cell" in each corner, at each opening and every 4-5 feet along a running wall. When you get to the top you put another pair of ring of #5s around the top and drop hooks down, lapping the "up" hooks. Knock small holes in these cores so you can tie the hooks, cover with plywood scraps and pour the cell solid along with the roof. You also tie rebar from the top ring across the roof.

Put a screen under the top 2 courses so they all don't fill up, unless you want them all full. Cut out the cells with the rebar and pour them solid. You will end up with a very strong bunker.

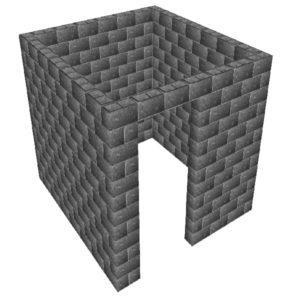

Do you mean lintels like these arranged this way? That makes a lot of sense and should be easy to do. I'm not at all sure about the corners, as you can tell.

That would give me over the 4" roof slab that FEMA recommends. Seems like way too much slab, though.

FEMA also recommends to "grout all cells solid."

Lay the steel form deck in before the last lintels are placed. Screw up from below into the seams to hold them closed.

Shore up the steel form deck with a "forest" of studs to hold it up during the pour and cure.

The block I am talking about is also called header block. It gives you a ledge for the decking and allows a continuous pour into the wall. The corrigated decking does have a fairly good span so you may not really need a forest of support. Check the spec.

View Image

Lay a course of that on top of what you drew. You might want to look into a precast lintel above the door tho.

Since you are going to have a truck and a pump there anyway for the deck/roof the difference of pouring all the cells is minimal

Thank you both. That is all very understandable.

I will work on completing the spec/design and post more.

For some reason the forum has stopped allowing me to post without moderation. Perhaps this one will get through.

- - - - - - -

I've added the full headers and the precast lintel over the door.

I still don't know what to do at the corners. What would you do in the real world?

Do you mean the hole when you use a header block in the corner?

You have 2 choices, You can cover the hole in the end with plywood before you pour the concrete or you can use a regular block and cut the notch out with a diamond wheel on a grinder. An old timer mason would do it with his brick hammer.

What you really need is the crew I saw do a two-holer bathroom building in Rio Bravo Mexico about 15 years back. Two old geezers and a kid, one very rusty handsaw, a couple of claw hammers and a couple of trowels. Only used standard 8x8x16 block, no precast header, poured roof.

For the roof forms they had a pickup load of assorted wood pieces delivered, none larger than about 3x5 feet.

A gas-powered mixer was brought in to mix the concrete for the roof. Consistency of soup. Was lifted to the top in 5-gallon buckets.

Turned out remarkably well, and sharp looking.

They built the pyramids with chisels and ropes but it is the 21st century. On a job like this get a ready mix truck and a pump.

You will be done in a half hour and the concrete will be a whole lot stronger.

It's just that it's amazing what can be done with very primitive tools and methods, if the workers have the skills.

The two older guys, between them, easily had 50 years of experience. I'd trust their work.

(The cement/solids ratio was VERY high.)