*

I am in need of some advice/warnings about making your own moulding.I am thinking of making a series of moulding to be made into built up, or the “poor man’s crown moulding”. Is there anyone out there that can enlighten me on the task ahead? (is it really worth trying, or should I just pay a near by woodworking shop to churn it out?) and Lastly, a question about router tables,If you had limited time and resourses what type of router table would you make, a horizontal or a standard mounted option? Thanks a lot folks for your time……….

Discussion Forum

Discussion Forum

Up Next

Video Shorts

Featured Story

Spray foam is a great invention, but it's not always necessary.

Featured Video

How to Install Exterior Window TrimHighlights

Fine Homebuilding Magazine

- Home Group

- Antique Trader

- Arts & Crafts Homes

- Bank Note Reporter

- Cabin Life

- Cuisine at Home

- Fine Gardening

- Fine Woodworking

- Green Building Advisor

- Garden Gate

- Horticulture

- Keep Craft Alive

- Log Home Living

- Military Trader/Vehicles

- Numismatic News

- Numismaster

- Old Cars Weekly

- Old House Journal

- Period Homes

- Popular Woodworking

- Script

- ShopNotes

- Sports Collectors Digest

- Threads

- Timber Home Living

- Traditional Building

- Woodsmith

- World Coin News

- Writer's Digest

Replies

*

The only reasons to make your own moldings: 1) you're using rare wood as a detail; or 2) you can't buy standard trim in the sizes you need.

A woodworking shop can (probably) do the job right the first time, and pretty cost-effectively, at that.

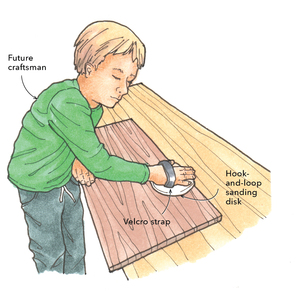

If you do it yourself, you'll need a table saw, a shaper, a router table, and apropriate sanding equipment (at the very least), along with the requisite skills to use the equipment. In other words, you need a complete shop to do a good job.

*

I am in need of some advice/warnings about making your own moulding.I am thinking of making a series of moulding to be made into built up, or the "poor man's crown moulding". Is there anyone out there that can enlighten me on the task ahead? (is it really worth trying, or should I just pay a near by woodworking shop to churn it out?) and Lastly, a question about router tables,If you had limited time and resourses what type of router table would you make, a horizontal or a standard mounted option? Thanks a lot folks for your time..........

*

Jarvis, that "poor man's crown" is generally the best way to go. Very wide crown has a tendency to cup, and never towards the wall or ceiling. If the crown is clear finished or stained, wider pieces would mean fewer joints, but it sure is harder to cope, bend, twist, and fasten in place.

You don't say how much crown you need, but here in North Carolina, it's about $250 for a shop just to set up for a special run. If you're going with paint, and don't have to precisely match anything that's already existing, you could build up yours from off the rack stuff. Different lumber suppliers do have some different styles, and sometimes millwork shops have extra pieces leftover from a custom run.

As for your router table query, if it's moulding that you're running, the vertically mounted router is much more stable, so you'll get a smoother finish. I mainly use my horizontal rig for loose tenons and small slots.

Good luck.