Columns (Tuscan style in this case) will often have the top face of the capital exposed around the edge as per the classical order. All the column capitals I’ve used for interior and exterior are basically hollow/open and easily collect water and debris if exposed. For interior applications, I fill with mud. What do others do for exterior applications?

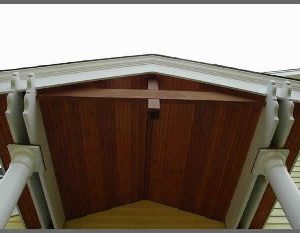

In the attached image, a copper cap is fixed. This is nice but will cost some time and $$ because I have several to do. Are there other options or do folks leave them open?

Edited 9/27/2007 12:33 pm ET by Mojo

Replies

One thing that's a bit unconventional in the image you posted is the pair of 2x's over the column as opposed to a single larger beam (or box beam). That leaves the centerline of the column open, which would otherwise not be a problem.

The flashing option is a good one, but I don't see why you couldn't make a cap out of some good, clear, 2x stock. I'd definitely want to see a bevel around the outer perimeter to shed water (approx 7-10 degrees). As far as the space between the 2x beams, it may not be as critical to have slope there, but I think it would be preferable. Perhaps a second piece of triangular cross section could be adhered to the top there to make execution easier.

You might also have a minor bird problem with the pictured design -- I can't believe how determined those little buggers are sometimes to find a place to live!

Edited 9/27/2007 2:05 pm ET by Ragnar17

The picture was from Google on 'Portico'. My application in this case will have the columns under a trimmed out beam where the outer 1" of the capital will be exposed on 3 sides. I like the idea of a piece of stock to cap the capital. Thank you.

I was kind of wondering if it was just a picture you had snapped or otherwise come up with.

If you only have an inch or two to cover, you could also consider "wrapping" that area with some sort of cap molding. Just make sure the cap mold is solid and has a sloped top surface. An integral drip edge or drip kerf never hurts either.

Being hollow cored columns I would have thought screened venting top and bottom was the norm.

sobriety is the root cause of dementia.

That's a good observation on the screening/venting.

To expand on the Rez reply, columns should be vented top and bottom to let air pass thru - a la chimney effect. This prolongs the life of the column by keeping the various minuscule bugs at bay. Upper openings can be screened, and lower vents can be lightly stuffed with brass wool if screen was not applied before install. The brass wool will keep out real bugs, but let air pass.

Dave S

http://www.acornwoodworks.com

I build the beams out, wide enough to have a reveal after the capital is fixed permanantly.

I use a hollow synthetic column, instead of wood. I can't remember the name of the material.

Plan ahead for the width of the capital and things go smooth.

Matt

This is a great question. I have been irritated by this for a couple years.

It seems that the intention has been to vent the wooden columns. I have been going along with this since I renovated some old wood columns and found the obvious intent.. and it makes sense. This is difficult however and I have no satisfactory solution for when the capital sticks out beyond the beam like its supposed to. I have had to cap them with a little piece of lead flashing or in another case a cap of Azek. Now those wooden ones are blowing out, showing a crack. I am looking at replacing some other wood ones with composit. The composit column presumably would not need venting? .. any thoughts. anybody..

thanks

arthur

Yes, the intent is to keep from having moisture rot the columns from inside out or swelling bust the glue joints apart.Several years ago, I installed a lot of all heart redwood columns from Hartman and Saunders. The install instructions clearly stated that they should nbe left open to vent at top and at bottom. ( Base was designed to have a no-show vent openning and top had a hole in the capital.)Some of these were in sheltered loactions where no more than a couple of drops of water would ever get in. They had trimmed beams and roof so I make some shims that maintained some vent space at the top without showing.

Some of them were right out in the weather under pergolas.

Within two years, the glue line were letting loose. When I contacted the company ( which in the meantime had changed hands, being bought out by a larger multinational) for satisfaction, they informed me that I was crazy to have installed wood columns outdoors with no metal caps to keep water out....I pointed out that I had installed exactly in line with their instructions written down in the book! I had also ordered the "Exterior grade" quality ones. Long story short, they had quit making that grade of column and had not changed the literature. They offered the ccstomer a choice of giving him all new columns( with him having to pay for labour to replace) in the FG composite model, or to pay for re-working these in place.So the latte was his choice. I reglued these failing seams with epoxy injections, and made coppper to slip in at the capitals. They have been fine ever since. That is about ten years now.But ever since, I use the composite, which are a third of the price and never rot. I have yet to find a customer who can tell the difference.For partailly sheltered ones, if I had to use wood columns per owner or architects dictates, I would cap tops with copper or lead, and leave base open to drain condensate out. I do not think that it is necessary to have the full chimney effect venting of an open top and it seems to let more water in than it helps to vent out.I am aware of another location where some cheaper wood columns were used and wereinstalled with no venting top or bottom by some guys who do nice trim work, but did not know anything about the moisture issues.

Within two years they were finding issues with those columns similar to what I described in mine above. They drilled some 1-1/2" pop-in vents in unobtrusive locations near the base of each to act as vents and weepholes. on some, water ran right out.but they have not had any problems since.I don't really know where the water came from, other than perhaps bleeding in at the capitals wheere only wood, paint, and caulk were protecting and sheeding rain.I have also replaced some columns for people where IMO, the first ones had been interior ones that got used outside. All the glue was failing, and it was plain old pine for wood. I tried a repair one year, by injecting gorilla glue, clamping things together with strap clamps and using bondo ,sanding, and paint. By the next year, the other glue joints I had not gotten were busting loose. So we replaced them - owners did not want to keep repairing every year.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!