How to Safely Store Bits in Your Router Case

Get your router bits to stay put and stay sharp.

Keep your router bits from rattling around

Brian Campbell from Minnesota City, Minnesota writes:

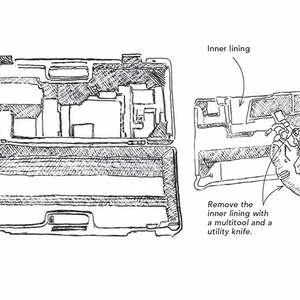

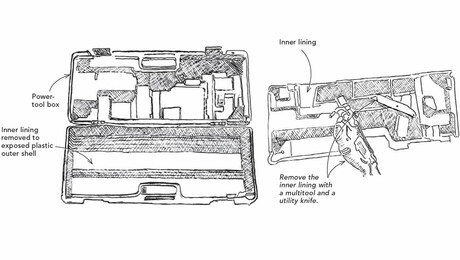

My trim-router tool case has several triangular-shaped storage compartments built into its plastic housing. They are handy cubbies for storing bits, but the bits just rattle around in there, banging into each other in the back of the truck and getting dull before I even open the case. I used some scrap pieces of foam insulation shaped with a scrollsaw to make custom storage inserts for my bits.

The foam is actually tough to drill. The bit wants to wander, and the foam has a tendency to tear out. My solution is to use 1/4-in. pegboard as a drill guide. It keeps the bit from wandering, stops tear-out, and gives you evenly spaced holes. A 3/16-in. hole provides a snug fit for the 1/4-in. shanks.

In some of the tighter spots, I drilled the holes at an angle to accommodate large bits. I secure odd-shaped bits to the foam board with electrical staples.

In this video tip, Chuck Miller used a piece of peg board as a drill guide and as a template for cutting the foam. He also used a tip from one of his previous videos: Clean cuts in rigid foam