FastenMaster just introduced an innovative screw-in bolt that replaces ½ in. through bolts called a ThruLok that I think deck builders will warm up to quickly. No need to bore a bolt hole, you just chuck the ThruLok head in a drill/driver and screw the bolt right through your wood to wood connection.

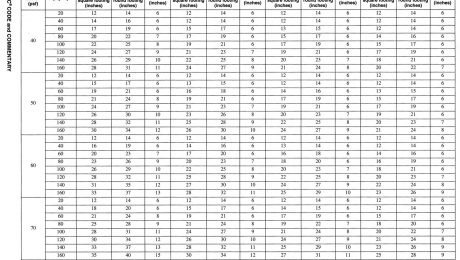

ThruLoks more or less replace ½ in. threaded bolts 3 to 2 – meaning 3 ThruLoks roughly match the strength of 2 – ½ in. bolts. Common uses are bolting posts to rim joists, beams to notched posts and posts to blocking. There are two technical bulletin links on the ThruLok web page detailing about a dozen different configurations using ThruLoks. ThruLoks come in 6 ¼ in., 7 in., and 8 in. lengths.

Installing a ThruLok is easy, you just have to follow some simple steps. Drive a ThruLok into the workpiece and stop about ¼ in. to 1/8 in. before the washer seats (photo). Then you spin the Hershey’s Kiss shaped nut finger-tight onto the screw threads poking through the other end (photo). Finish driving the ThruLok with the drill / driver until the washer snugs against the work. In the last few turns the bolt tightens into the nut and pulls the connection tightly together. Two small windows on the nut show a minimum engagement point so installers and building inspectors can make sure each ThruLok is securely attached for the rated capacity (photo).

I tested a dozen sample ThruLoks by attaching kiln-dried-after-treatment pressure treated southern pine 2×8’s to like-dried 4x4s. It took a few seconds for the drill points to carve into the extra dry SYP before the threads grabbed; but soon as they did, the ThruLoks drove through in half a minute. To shorten the delay in thread bite, I rapped a couple ThruLoks in ½ in. until the threads hit the wood. The threads engaged instantly when I started the drill / driver and zipped right through the wood.

According to the FastenMaster website, ThruLoks should be available at pro lumber dealers across the US so if they aren’t at yours yet – ask. Expect to pay $2.50 – $3.25 depending on length and quantity. So how does that compare to the cost of bolts? My local yard gets $3.15 for a 1/2 in. galvanized 6 in. bolt with washers and a nut. Figuring I’d need 3 ThruLoks to match 2 bolts, I’ll spend an extra buck on the ThruLoks but save more than that on the install labor since I don’t need to bore the holes.

View Comments

Mike,

I couldn't tell from the description here or on the FastenMaster page you linked to, but when talking about post to joist conection are you referring to railing posts? If so, it seems that these would be great to replace the Simpson HD hardware required to meet the 200 pound load minimum. Even with the new Simpson brackets that came out earlier this year, the elimination of placing and drilling that bolt hole certainly would make up for the extra cost of the bolts.

Paul

hipaul - ThruLoks can be used in conjunction with Simpson Strongtie's DTT2 or USP DTB2 brackets to provide the 200 lb design load (which actually translates into 500 test load) for the guardrail post to deck frame connection. When a post lines up with a floor joist then you'd still have to use a 1/2 inch bolt through the rim, post and connector because Simpson and USP require that; but the bottom bolt (which has no hardware connected to it) can be replaced with a ThruLok.

Most often, my posts end up somewhere between joists so I'd use 3 ThruLoks to mount the post to the rim board; then I would still mount DTT2s or DTB2s to the joists on either side of the post to reinforce the rim to frame so the rim is secure enough to resist the load on the guardrail post.

When I saw FastenMaster's display deck frame at the Deck Expo last month where they showed ThruLoks in place, I was excited because there were no hardware brackets. I assumed they figured out an alternative to the hardware solution to provide the a code-compliant solution for the guardrail post to frame connection. The FastenMaster rep told me that wasn't the case. I suggested that they do some additional testing with blocking and ThruLoks and maybe some LedgerLoks to give us some more options for making a secure connection.

As more deck builders install composite and plastic guard rail systems the post to frame connection will become more of an issue due to the ASTM D7032 requirement noted in the code - but that's another blog topic for later.