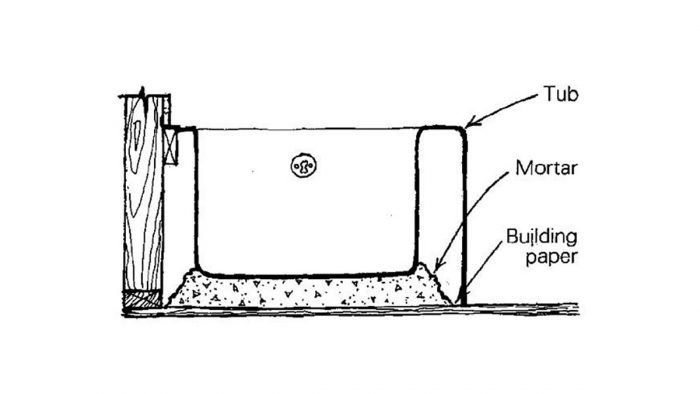

If you are about to install a lightweight steel or fiberglass tub, here’s a way to make it feel more substantial. Set it on a bed — or rather a blob — of mortar.

First staple building felt to the subfloor in the area to be occupied by the tub. Spread a thick, stiff blanket of mortar onto the felt so that it will cradle the bathtub, as shown in the drawing above. What was once a flimsy tub bottom with no thermal mass is now solid as a rock and able to retain warmth. It’s a very nice touch if you can’t use cast iron.

Kurt Lavenson, Berkeley, CA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #26

View Comments

Spray foam works just as well with a lot less weight and effort.

My plumber used to use Structolite (plaster base) for that purpose. It might be slightly easier to work with.

As a residential remodeler, we find the tubs we remove set with the spray foam technique (although very easy) tend to fail (compress and break apart) over time under the weight of the water and people using the tub. There's also the point Kurt Lavenson made in the original tip: the spray foam doesn't provide the thermal mass that mortar does. A tub set with mortar stays warmer a bit longer.

I was thinking of using spray foam on the next tub I set and also spraying all the cavities with it for insulation as well. As for mortar having more thermal mass, I would think that cold mass would absorb the heat from the hot water in the tub until they were the same temperature, quickly cooling the water. It would be an interesting experiment.

Spray foam doesn't work. Mortar beds are the only way to go.