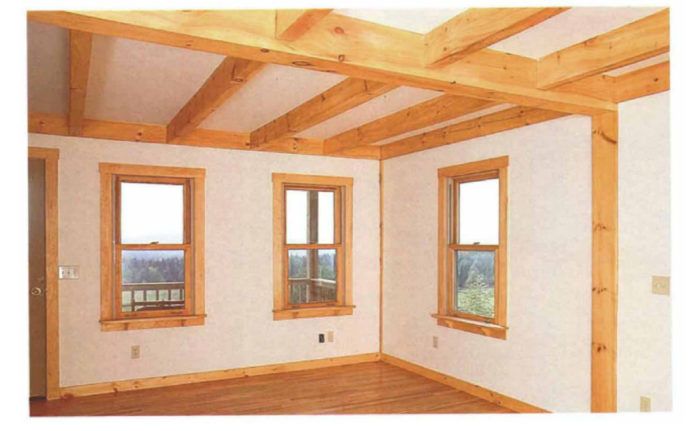

Synopsis: The author describes a way of building timbered ceilings while taking advantage of the economies of stick-framed walls. His approach offers the appeal of traditional timber-framing without all of the expense. The article also offers a quick look at some joinery methods for timbers.

Traditional timber frames have an undeniable aesthetic appeal. And coupled with high-tech materials like stress-skin panels, they’re energy-efficient. But modern milling and assembly systems notwithstanding, timber framing is still more labor-intensive than stick framing and imposes severe constraints on the layout of mechanical systems. Whatever the merits or disadvantages, no one can claim that timber framing is inexpensive. As a builder living and working in a relatively poor rural area, my typical clients are well educated, seriously underpaid urban refugees — people with timber-frame tastes and stick-frame budgets.

Probably because I enjoyed the sheer sensuality of timber joinery so much myself, I tried to find a satisfying compromise between the absurdity of appliqued wood-grain plastic beams and the expense of genuine mortise-and-tenon joinery. Some builders attempt to create a timber-frame effect by notching a center beam to receive one end of the joists while carrying the other end on standard exterior wall plates. With this construction, it’s impossible to finish off the junction of the interior wall and the joist penetrations in a way that doesn’t look clumsy or forced.

Ceiling treatment is also problematic with a timbered ceiling. Although V-grooved 2×6 decking installed over the joists has the advantage of providing finish ceiling and floor (or sub-floor) simultaneously, it restricts mechanical systems to exterior walls, partitions, dropped ceilings and chases routed into beams. And even with sound-deadening board between the decking and a wood finish floor, people downstairs will experience the pitter patter of little feet as a jackboot fandango.

Grappling with these and other difficulties within the framework of tight budgets, I devised a framing system using heavy timber ceiling joists that combines the speed and flexibility of conventional stick framing with the aesthetic and structural benefits of timber framing.

Pine woodworking

I use native eastern white pine for all my timbers. Pine is more stable than hemlock and white spruce, the two other readily available timber species in our area. It shrinks, checks and twists much less as it dries in place. Also, pine works easily. It has a uniform grain, so there is less danger of splitting the wood when cutting joints.

Timbers are best worked when green, before they’ve had a chance to bow or warp. You can’t force a crooked timber into true, at least not without a come-along and some means of permanently maintaining the pressure.

Some builders might wonder if pine is suitable for structural use. In general, timber framing has an inherently greater margin of safety than conventional framing. In particular, with the relatively light loads typical of residential construction, and with short spans and over-size timber cross-sections, timber strength has never been a problem. With this particular system, only the central girder, or summer beam (from the Old English term “sumpter,” a pack mule bred for shouldering heavy loads) carries a significant load unassisted, and is therefore greatly oversized.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Sledge Hammer

Smart String Line

QuikDrive PRO300s