Q:

I’d like to lay tile over an area where half the floor is a post-and beam with diagonal 1-in. subflooring, and the other half is a concrete slab on grade. I’m concerned that the two types of floors will move independently. Is there a way to install the tile that would inhibit the potential for cracks?

Thomas E. Smith, Burlingame, CA

A:

Michael Byrne, a tile contractor in Grand Isle, Vermont, replies: First, you should contact a qualified structural engineer to determine if the slab is properly supported and stable and if the post-and-beam side of the floor can carry the additional weight of the installation without flexing.

The tile industry—through the American National Standards Institute A-108 Installation Specifications (11 W. 42nd St., New York, N. Y. 10036; 212-642-4900) and the Tile Council of America (P.O. Box 326, Princeton, N. J. 08542-0326; 609- 921-7050)—specifies a deflection no greater than 1/360th of the span for floors that will be covered with ceramic or stone tiles. If your floor exceeds this requirement, the engineer may suggest ways to bolster the existing structure.

Both sides may be rigid and stable, but with seasonal changes, exposure to moisture and shifts in temperature, the slab side could move independently of the post-and-beam side. This movement will cause cracks in tiles that have been adhered directly to the substrate with thin set (a shallow mortar bed). To reduce cracking, you can place tar paper or polyethylene film over the subfloor. I use Nobleseal TS (The Noble Co., 614 Monroe St., P. O. Box 332, Grand Haven, Mich. 49417; 616-842-7844), which is the only membrane material that has consistently performed for me. Then float a 1-1/4-in. to 2-in. thick reinforced (with 20-ga. galvanized mesh) mortar bed over the membrane and install the tiles in adhesive over the hardened bed. With a minimum 1/4-in. expansion joint around the perimeter of both the mortar bed and the tiles and with the membrane working as a slip sheet, the installation is free to ride out normal expansion and contraction without damaging the tiles.

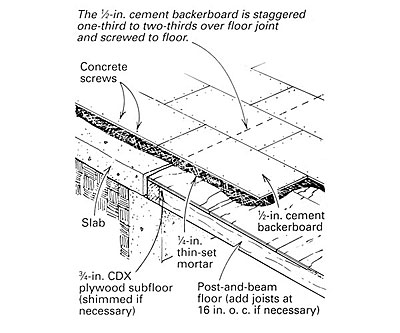

If the profile of the thick-bed method is too high to suit the structure, you could use this thin-bed method: Remove the 1-in. subflooring and replace it with 3/4-in. exterior plywood, shimmed, if necessary, to the height of the concrete slab (joist spacing must not exceed 16 in. o. c.). Leave at least a 1/4-in. gap around the plywood floor. Then cover both the plywood and the slab with cement backerboards, such as Duroc (US Gypsum Co., P.O. Box 806278, Chicago, Ill. 60680-4124; 800-621-9622), that are placed in a bed of multipurpose thin-set mortar compatible with both plywood and concrete (Bonsal Flexible Multi-Purpose Thinset, Bonsal, P.O. Box 241148, Charlotte, N. C. 28224; 800-334- 0784). Stagger the backerboards over the joint between the two floors and continue the 1/4-in. expansion joint between the backerboards and the wall. Then secure the backerboards with screws. On the slab side, use concrete screws, which are sold with a special carbide bit for penetrating the concrete.

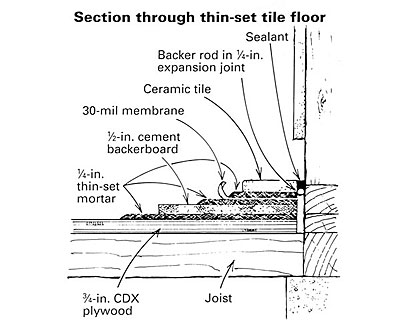

Before you set the tiles, isolate them from substrate movement by troweling another layer of thin-set mortar (see drawing), covering it with the 30-mil plastic membrane and then spreading a top layer of thin set into which you set the tiles.

When you install the tiles, leave a 1/4-in. expansion joint around the perimeter, plug the joint with backer rod (Industrial Thermo Polymers Ltd., 1255 Lorimar Dr., Mississauga, Ont., Canada L5S 1R2; 800-387-3847) and cap the rod with a bead of resilient caulk or sealant (Color Caulk, Inc., 1696 W. Mill St., Unit 14, Colton, Calif. 92324; 909-888-6225) to keep the joint unclogged and free to move.

For an extra measure of flexibility, make sure to mix a latex or acrylic additive into the grout or use grout with a built-in dry polymer.

As with any job, there are risks. Get your engineer’s report, contact technical reps for all the materials you plan to use and see if they will OK the installation. If everyone agrees, follow all printed instructions explicitly and welcome an installation inspection by one of the technical reps if it’s offered. If only a minority of the technical reps approves, and you still want to go ahead with tile, get a performance statement in writing if you can from the technical reps who approve. Do a scrupulous installation, but don’t be surprised when problems appear.

Finally, there are situations where tile simply does not belong. If everyone you ask gives a thumbs down on the project, take the advice and look for an alternative material.