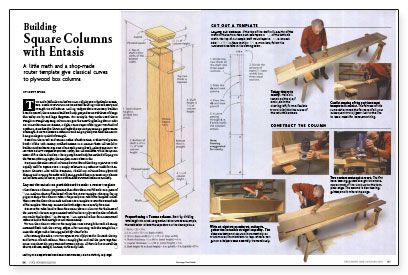

Building Square Columns With Entasis

A little math and a shop-made router template give classical curves to plywood box columns.

Synopsis: This short article describes the construction of a classically shaped column from plywood parts. The author explains “entasis,” the use of a slight curve in the upper portion of the column to give the impression of greater strength.

Two and a half millennia before CAD, cell phones, or hydraulic excavators, Greek construction crews erected buildings whose beauty and strength we still admire. Lacking widgets that 21st-century builders brand essential, these ancient builders firmly grasped some subtleties of design that today are by and large forgotten. For example, they understood that a straight or straight-tapering column can give the unsettling feeling that its sides are somewhat concave. Entasis, a slight, convex taper of the upper two-thirds of a column, remedies this illusion and tricks the eye into perceiving a greater sense of strength. Entasis elevates a column from being a purely structural element to being an elegant symbol of strength.

Based on the Greek and Roman orders of architecture, architectural pattern books of the 19th century codified entasis in a manner that’s still useful to builders and architects. Reprints of one such pattern book, Asher Benjamin’s The American Builder’s Companion, are still available. While Benjamin treats all five classical orders, I have paraphrased only his method of laying out the Tuscan, the simplest, most robust order.

Benjamin describes round columns, but I’ve found that his proportions work equally well for square ones. I simply substitute my columns’ width for Benjamin’s diameter. Also unlike Benjamin, I build my columns from plywood, shaping and mitering the sides with bearing-guided bits in a router. My columns are not structural; however, you could enclose structural columns similarly.

Lay out the entasis on particleboard to make a router template

I first derive a column’s proportions, then draw them out full scale on a piece of ½-in. medium-density fiberboard. I’ll use this router template to shape the column’s sides. I shape only one side of the template at first. Then I rout the first column side and use it as a template to rout the second side of the template. This step ensures that both edges curve exactly the same.

Because the sides bend to form the entasis, there is a limit to the thickness of the material. I haven’t experimented with lumber or plywood (either of which can work) thicker than ½ in. However, ½-in. material is fine for nonstructural columns and is thick enough to nail conveniently.

To trim the column’s sides to the template, I use a straight bit with a bearing mounted flush with the cutting edges. After trimming with the straight bit, I miter the edges with a bearing-guided 45° chamfer bit.

For more drawings and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Lithium-Ion Cordless Palm Nailer

N95 Respirator

4-Gallon Piston Backpack Sprayer