I make a lot of frame-and-panel doors for my cabinets. Sometimes my clients want a molding to wrap the inside of the frames.

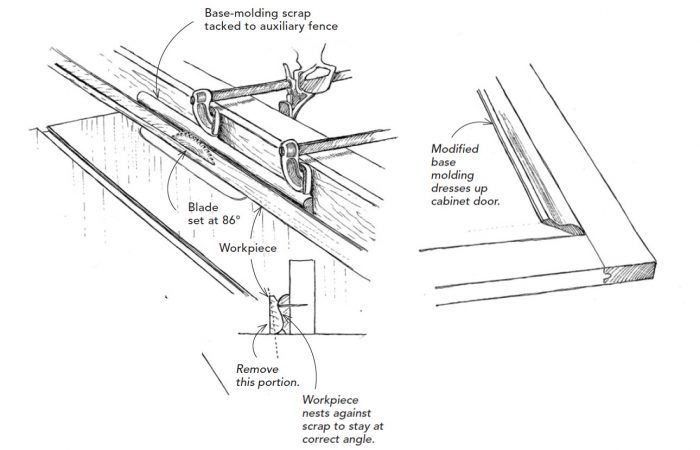

The other day, I was trying different stock moldings, and they all stuck up between 3/8 in. to 1/2 in. beyond the rail and stile. They just didn’t look right. So I decided to run a piece of molding through my tablesaw, taking a slight angle off the back, as shown in the drawing (left). I placed the modified molding on the door, and it fit like it was meant to be there. This was so simple, but in 39 years, I’d never thought of it before.

I used a pin nailer to affix the trim to the rails and stiles. I used glue at just the miters. For a paint-grade door like this, the paint acts as an adhesive.

The molding shown here is called a base molding (Brosco #B658). You can find similar profiles at a lumberyard or even a big-box store. I set the sawblade at 86° for this molding (or 4° depending on how you look at it). Incidentally, I never push moldings this narrow all the way past the blade. I run a longer piece than needed and stop the cut before getting to the end. Better to waste a little wood than endanger my hands.

Click here to enlarge the illustration

—Thomas William Guevin, Dorchester, MA

Edited and illustrated by Charles Miller

From Fine Homebuilding #212

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Reliable Crimp Connectors

Affordable IR Camera

Handy Heat Gun