One of my brothers has a colonial with two upstairs bathrooms. The builders who did his house clearly had enough good sense to include bath vent fans, but not enough sense to vent them properly. Both fans had the standard 4″ flexible metal ductwork just laid carelessly on the fiberglass insulation.

So, last weekend my brother and I planned our attack: run new R-8 insulated flex duct from each of the two fans (about 20 or so feet apart) and join those ducts to backdraft dampers that flow into transitions to a 6″ wye that vents out a rooftop exhaust vent.

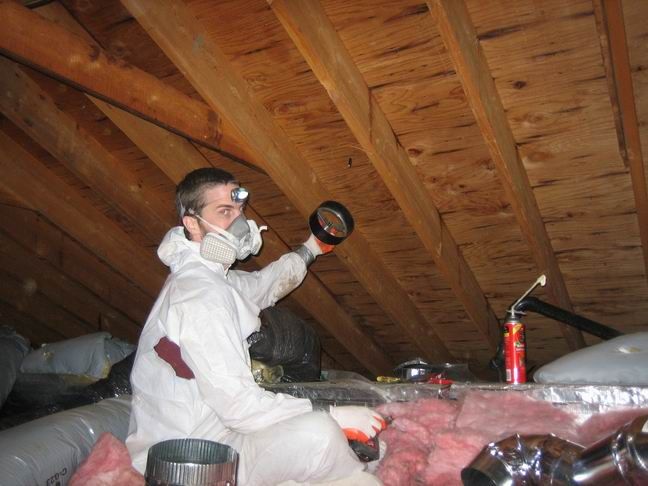

Since we were headed into a dense population of fiberglass insulation, donning full coveralls, with gloves duct taped tightly to our cuffs, respirators in place, and head lamps switched to the on position, we took extra care to make sure we weren’t going to have to climb back down to retrieve some forgotten tool, clamp, or roll of foil tape and track all sorts of fiberglass to the rest of the house.

The planning paid off, and we didn’t forget anything. But, we still hit a snag.

The ducts were hooked up, the wye was pre-assembled to the transitions and dampers and ready to put into place. Time to drill the hole. I chucked up a brand new, 100% unused, still shiny 6″ Malco holesaw that sells for $70. I fed the pilot bit into the underside of the roof sheathing, then just as the holesaw teeth touched the sheathing, the bit sheared off.

Did I mention that this was the first hole…ahem, hole attempt for this tool?

So, how do you improvise a hole in the roof when you’ve carefully planned out every tool needed for the entire job and one of them fails? Easy, you swear a lot, then climb out of the attic, dig out the reciprocating saw that you just happen to have in your collection of tools, find a really long extension cord, and finish the hole from the roof.

By the way, the bit is replaceable, so the tool isn’t rendered useless. So there’s that, at least!

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

8067 All-Weather Flashing Tape

Affordable IR Camera

Reliable Crimp Connectors

View Comments

I guess you learned my lesson to always carry a spare bit AND the little wrench/screwdriver/thingy needed to change it whenever you bring a hole saw to the party. I think I would have kept a cordless recip handy for emergancy use, but hindsight is always 20/20.

Important thing is that the job got done.

"in full protective gear"

Isn't that a big rip in the protective gear under his arm?

stupid Tyvek coveralls...by the end of a job they're always ripped open on me.

I've always wondered about venting bathroom exhaust fans via a rooftop exhaust vent. In places that don't get snow or ice I don't see it being a problem, but what about places that get a lot of snow in the winter? Would the warm, wet exhaust melt the snow and cause ice back dams? I need to redo a bathroom exhaust fan and I'm thinking about going out a gable wall, same for the kitchen exhaust. The only thing I see going out the roof that wouldn't melt snow is the vent stack for the plumbing? Has anyone had any problems, or does the bathroom exhaust not run enough to cause a problem?

(Ads, Ads, Ads. Bah, humbug.)

Up in a roomy attic doesn't even come close. Try it under a house where you have to crawl on your belly and drag in all the tools.

A couple points.

Josh's concerns are correct regarding ice damming. The roof penetration should be stripped down to sheathing, and protected with snow-and-ice shield onto the felt and lower shingle courses. Then the roofing reconstructed around the new vent.

We found a new definition for protection with the Tyvek suits. We were wearing some one afternoon and one guy had bought a couple bean burritos off the lunch truck. At the end of the day when we took the suits off, it became clear his suit had been protecting the rest of us . . . thankfully he drove himself home.