The Precut Porch

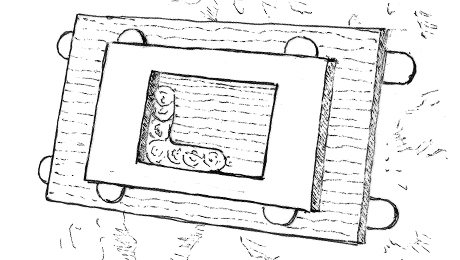

A detailed SketchUp model and cutlist allow much of this portico’s prep work to be done in the shop.

Synopsis: Remodeler Michael Patterson explains how he saves time by using SketchUp to create a detailed computer model and cutlist for a project and then cutting as much of the lumber as possible in the shop rather than on the job site. He illustrates his process in this article with a portico. He was able to truck the components to the site in one trip and then assemble them quickly.

Make it look like the pretty picture. That’s our job as carpenters — to bring someone’s ideas to life in three dimensions. Sometimes, though, the carpenter and the customer have different visions, and details get lost in the translation. Avoiding that issue is one reason we have drawings.

There’s another reason as well. Good drawings help me to complete the work quickly. A recent project where I built a portico on top of an existing concrete-and-brick stoop provides a good example of how drawings speed my work. Efficiency starts with thinking the details through beforehand. That sounds pretty obvious, if only because every job needs a materials list, a plan for how to proceed, and a time estimate. But in cases such as this small portico, I expand the concept. In the past, I would have estimated the rough dimensions of the parts and pieces to order the material. Once on site, I’d have figured out the exact dimensions of the framing, cutting the pieces to size just before installing them. Next, I’d have measured the installed framing to determine the sizes of the trim pieces, spending a lot of time running up and down a ladder. Complicating matters would be doing all that outside.

A few years ago, I started tackling smaller projects by first developing a detailed drawing and a cutlist with the exact dimensions of nearly every piece in the project. From that detailed list, I cut as much of the project as possible in my shop, right down to the trim. I usually still have to cut a piece or two on-site when existing conditions vary enough to make precutting dicey. Even on those pieces, though, I still do as much dimensioning or shaping as possible in the shop.

The advantages are obvious. The cutting is done with shop tools, which tend to be more accurate than job-site tools. Much of the work is done out of the elements, and because the on-site time is minimized, there is less disruption to the client’s life. My shop is at my home, so I have no commute, which is nothing to sneeze at in the traffic-clogged Washington, D.C., area. I also find that I can complete the job more quickly, in part because my trips up the ladder are only to install the components, not to measure for them.

For more photos, drawings, and details, click the View PDF button below: