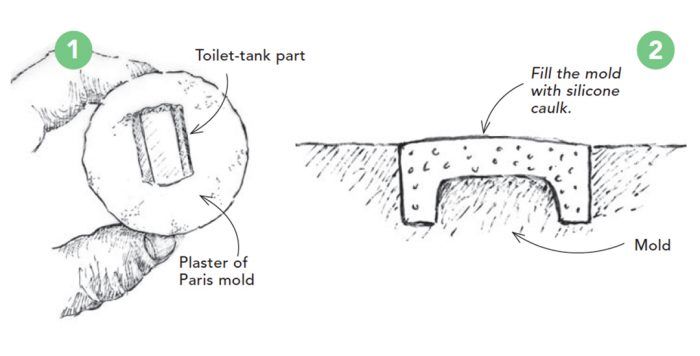

How to Make Custom Rubber Parts

Silicone and plaster are all you need to reproduce hard-to-replace rubber bushings, gaskets, and more.

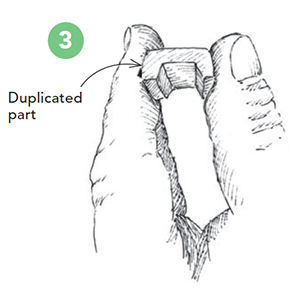

I needed a small rubber part for my toilet and I could not find a replacement anywhere. Fortunately I still had the old one, so I figured I could make another. I set the original piece in a plaster mold. Once the mold was set, I put 100% silicone caulk in the mold and let it cure overnight. By morning I had another matching piece that worked fine. I am sure this technique could work for other hard-to-find rubber parts.

—Eli Gluck, Brooklyn, N.Y.

Edited and Illustrated by Charles Miller

From Fine Homebuilding #282