Floor: Plywood replacement for particle board?

I am finally tackling a change-out from carpet to bamboo flooring in my home studio. My boyfriend has convinced me that we can do this ourselves since its a floating floor with a lock/click system. I like to think I am an above average handywoman around the house but not sure if this will be above my skillset. I am attempting to fully educate myself on the process but there is one area where I am hung up — removing the 1/2″ particle board that is currently below the carpet (and above the OSB) and replacing it with plywood.

From what I’ve read, this is good to do because particle board can swell from accidental moisture and plywood is much more stable if moisture is present. But, ways to secure the plywood to the OSB and other questions I just cannot find absolute answers to (thus the reason to hire the pros, right?).

Currently have 1/2″ particle board over OSB. If we replace the particle board with 1/2″ plywood:

- What kind of plywood do I need to get? (I am realizing there are a variety of different types of plywood)

- Do the plywood sheets all need to run the same direction (like all the long 8′ way or can I run some the long way and the others the 4′ direction? Or does it depend on what way the joists/trusses are running?

- How do I secure the plywood to the OSB? Screw it down? I’ve read different things from nailing to glue and screw it down. What is the correct way to do this?

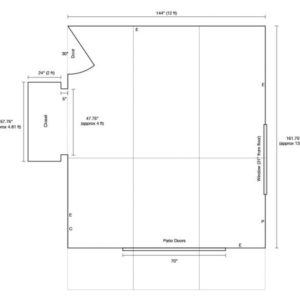

I am also including a drawing of the room in case it helps…

Thanks for any advise!

Greta Girl

Replies

Greta

Here's my thoughts-you are correct to get the PB up and outta there. It might be stapled, it might be underlay nailed. Either way, it'll come up hard...............

I take a sacrificial blade and set the depth in my circ. saw to the thickness of the PB. I score it in 2x2 or 2x4 (across a sheet).........whatever makes it manageable to "attempt" to pop it up and get it out. YOU MUST USE SAFETY GLASSES if you score it-Shrapnel!-hot metal does fly, you can't avoid it.

If you can get or have 3 or 4 "wonder bars" which are the slightly bent flat wrecking bars about 16" long-you "attempt" to get them under the PB along the edge and drive them under in unison (about 8" apart or so). Either it will come up as a pc or you'll end up cussing and moaning and popping up 4" chunks................

Pull or drive down the staples or nails which won't probably come along with the PB as you take it out. KNEE PADS!

Now, why are you adding to the OSB? Are door trims cut short of what your finished floor will be? Is the subfloor less than 5/8"?

If it would work to not add more ply-screw the subfloor down to the joists with subfloor screws (if you can get 'em, mine come in a strip for the stand up screw gun) don't use drywall screws-they'll snap. Maybe deck screws are more available. Screw every 6" on seams and ever 9" to a foot in the field-you can tighten that up but it shouldn't make that much difference. If you've got a squeek area, definitely put em closer together.

Will answer the rest of your questions if you absolutely need to add ply.

Thanks so much for the great tips on removing the particle board. I do have some pry bars (and knee pads too).

The reason for adding the plywood would be to make it the same level as it was before (not a great answer, I know, but I don't know why the particle board is there now either). Adding the plywood would butt it up to the particle board that's under the carpet in the hallway. I am putting in new closet doors and a new door on the room so there won't be any issues there. (Oh, yes, there are some squeak issues that need to be addressed).

I've also enclosed a photo of the layers that are in the room now.

greta

Plan your ply thickness (of that transition where you're leaving carpet) to how you're laying/trimming the floating floor.

Remember, there's a minimal (or thicker) pad under that floating floor system. The click/loc bamboo from Teragren is nice, Kaars is sweet as well.

In/out doorways is a trick sometimes with any clic/loc brand. Sometimes you shave the nub off the toungue and glue the door/opening pcs. together.

For the ply, I'd be tempted to use staples as most underlay is fastened in that manner and holds well if done properly. You can of course screw it. If you lay it across the joints and stagger from the osb seams, you'll get the most span strength. If you're looking at it as more of an underlay, you could lay it in any manner that works for ease of install. No need to break on a joist with the underlayment.

That's assuming the subfloor is at least 5/8's and joist centers 16oc.

Best of luck.

Thank you again. I hadn't thought to look at the thickness of the pad (it's 1/8"). And also the staggering of the plywood makes good sense. I'll post photos when I'm done!

greta

Any other questions, please ask. There's minds here that haven't responded to your post yet. You should be able to get further information that might help you along.

Funny thing about remodeling. Staying ahead of calamities yet being able to adjust to conditions are sometimes missed by the novice. Insurmountable detours just mean finding another road to take. The funny part is that you might not have gps directions available...........

Besides, you should be keeping your eyes on the road.

Best of luck.