Okay, chastise me if you must. I can take it. But, we carefully laid out the tubes in our basement to accommodate for future walls before we poured the slab. I took pictures and documented where the walls should go. However, just two short weeks later, I realize I want more walls! The problem is that we can’t just go nailing frame walls to the floor. Is there a method for attaching the frame to the floor without nailing through? These are non-load bearing walls. Has anyone done this before? Surely I’m not the first woman to change her mind! ha ha ha

Thanks! Paula (PDF on the old board)

Replies

If you have pictures, can you locate the tubes to within a half a foot? The tubes are often routed 12 or 16" apart so you if you can get enough accuracy to power nail in a target that size you'll be ok.

Another idea, since your slab ought to be 4" thick, there should be almost 3" of concrete above your tube. Size your nails so that only about 1 1/2 " penetrates.

Use construction adhesive to assist and just enough nails to make the wall bottom so you won't kick it out by accident.

How's this sound to the rest of you out there?

ummmm....careful Norm.

Paula, unless you were present at the pour and watched like hawk and are absolutely, positively sure that none of the tubing floated......

I've got a hotter spot in my kitchen. Know that the tubing must be closer to the surface.....but sure didn't see it during the pour.

Shelley

good point, SBPERKI,

When pouring a slab over radiant PEX tubing I like to put the 6x6" wire mesh over my tubing (staple the tubing to the XPS foam sheets, lay they mesh on that and then place the cement).

It keeps the tubing on the bottom and keeps the mesh at least 1" above the bottom. Best for both, I think.

Yeah, that's the way we do it here too. But I've got this 3'x6' section in my kitchen that must have floated up some way. Only part of the whole house that actually feels warm to the feet when the zone is on. go figure.

it could be that the tubing is down where it belongs, but that the spacing between them is closer than in other places, or that it is nearer the beginning of a loop than other places (the closer to the boiler the hotter the water), or that the heat loss of the room is less in that area than in others (furniture, windows, etc.), but I'm just guessing.

How about this: size the nails for only about 1/2 " penetration (just BARELY enough to prevent movement if someone hits the wall) and use adhesive for backup?

Paula

I have/had the self same problem, and managed to 'find' a pipe as a result of what I assume to be movement during the pour. C'est la guerre.

Fortunately, a hole in a pipe is a fixable problem if you know about it. I happened to use Tapcon screws (because I have no luck with concrete nails) and you know right away when you drill a hole into a pipe under pressure. I suspect nails are a more iffy proposition and likely to result in a slow leak, at least until the nail corrodes away, by which time the water damage would be considerable.

As things went along, I would use high end construction adhesive and forgot most of the screws. I made most of my walls from steel studs and experimentally glued a short piece of stud to the floor in a closet. I suspect I will have to chisel it off. Wood seems to be easier to remove, but pretty well stuck down.

If you think about it, the walls are unlikely to fly into space if they aren't nailed down. Most are probably anchored to a wall at both ends anyway. The worst case would be around a door, which could wiggle loose with time. I just 'pinned' the studs down on either side of the doorway. The good news is that you only need to drill an inch or so for tapcons to hold real good, and they don't have to hold well to serve as pins.

I suspect it is overkill on my part. Nothing has moved yet.

Brian

I actually would have no concerns about adhesive on the bottom of a non load bearing wall....if the inspector buys off on it. Some of the new stuff is pretty amazing.

As far as what happened to my own installation....pretty much sure that it's a surface thing, rather than the others.

Don't know what it's like other places, but around here a large pour is pretty much apparent chaos. Lots of guys, lots of concrete, lots of noise, lots of yelling, trucks coming and going, English not in use. For all I know someone said, "I just kicked something loose" and someone else replied "don't worry about it, they'll never know" :o)

Shelley

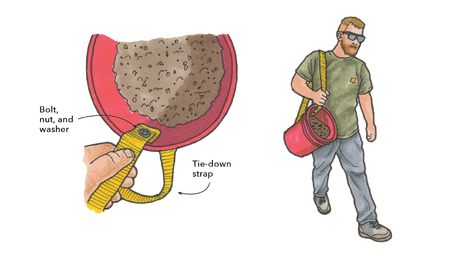

To follow up on Piccioni's thought that walls typically connect to other walls: you could cut out plywood "T"-shaped gussets to secure the bottom plates of the newly-specified walls to the previously sited ones. Go to town with some 2" screws and cut the studs in that area 3/4" shorter.

And how about two-part epoxy? Sure, construction adhesives have gotten better, but when I've tested an epoxy joints to failure, the unepoxyed wood breaks before the joint does.

David Thomas Overlooking Cook Inlet in Kenai, Alaska

I'd go (have gone) with subfloor adhesive. The better ones, esp. those with urethane are almost like welding. I did a test once when I was worried about some sleepers I was putting down. Took a 1X2 scrap and stuck it to the concrete floor of my shop with a dab of PL400. I forgot about it until I tripped over it the next day. Banged it off with my framing hammer and it took some concrete with it. I didn't clamp or weight it, just pressed it into the gob of glue. The urethanes expand as they cure so a little bracing side to side on the floor plate should do it. Push down with a wedged 2X4 if you think it needs it.

By the way, David Thomas has suggested the absolutely best way, but its messy. You must mix two parts together, as well as a filler.

Best of luck...........

Ahem!..I meant Paula. Newf, you should be in here: Hey, hey Paula (song from my youth)

Alan Jones

Edited 5/1/2002 7:12:45 PM ET by ALANSENOJ

Paula,

If you use a good quality construction adhesive on the bottom plate I don't see any reason for concern. Needing more walls and not knowing where the tubing is happens to everyone if they build on slabs long enough.

What I do is once the wall is in position then every few feet I drive a short case-hardened nail (actually an 8d sinker will work if the concrete is green) just far enough to nick the concrete. In other words, as soon as you feel concrete instead of wood, one more firm tap and stop. We're not even talking about 1/8 inch of penetration into the concrete, just a nick.

This will be enough to keep the wall from sliding around while the glue sets up, but not enough to puncture a tube.

Some of the newer adhesives are amazing. More than enough to hold interior walls in place.

Dave

PL Premium is a urethene adhesive that will weld your bottom plate down. Wedge or weight it in place overnite. Then built the walls next day.Excellence is its own reward!

Thank you so much everyone! I really appreciate your responses.

Paula