I’m just about fed-up with the new laws/rules they keep coming out with for imported housing here in Japan. I’m just a lowly Canadian carpenter here (learned the trade here in Japan), and I build American style homes here in Southern Japan, but they just keep making it harder and more expensive to build North American style homes here.

Here the architects pretty much rule the roost. I get the blueprints/specs for a house and do the framing (or put together the panels), insulation, drywall, flooring, windows, doors, cabs, trim, etc. The laws here for imported housing are 10 times as strict as they are for regular Japanese Post & Beam houses, even though its been proven time and time again the 2×4 homes are much stronger and last longer.

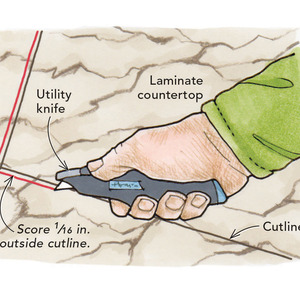

Anyway, the architect for the house I’m building now came to the house the other day to inspect my drywall hanging. I have to use 1 1/4″ screws at 6″ in the field and 4″ at joints. Its the same nailing/screwing schedule for the 1/2″ sheathing on the exterior. The new laws here account for the drywall being an interior sheathing. In other words, the drywall on the interior counts as structural.

Has anybody ever heard of this in North America? I’m sure its not prevalent. I don’t mind doing the drywall as the architect has specified, but these days it seems to be going overboard.

SS

Replies

i've read of DW being structural but have never seen it. What's the motivation behind it? EQs? Or are they picking items from Canadan & US codes and pasting them into their local?

Somebody here in Japan must have read something about drywall being structural..... and they took it to the limit....

They don't get it right though, trust me. Lots of companies/architects, etc. here take ideas from North America, but the techniques are applied wrong. They drywall but don't tape it, they do housewrap but staple it like crazy and don't tape any seams, etc.

Guess the framing here is strong though. All my roofs are still stick framed, all rafters sit on a 2x10 or 2x12 ridge beam. Framing hardware everywhere and all color coded nails/nailing.

The drywall thing has been a pet peeve of mine for a while though, especially when the architect comes in with his tape measure checking my screw pitch...

SS

Back in MI, you'd get run out of town if you put ONE screw in the field! They glue and then screw (or nail) under the tape only. Nothing in the field on the walls. The lids are double screwed in the field in three spots on each frame member. Bob's next test date: 12/10/07

Edited 5/24/2008 10:48 am by Jim_Allen

I'm in Michigan also and my inspector required at least 2 in the field on every stud

LIVEONSAWDUST,

Where in Michigan. I am in the Allegan area.

Russell

"Welcome to my world"

I,m in North Muskegon

I've really only worked in Macomb and Oakland. They don't have any drywall inspections. There is no reason why drywall needs to be inspected. I have never heard of drywall falling off any wall. Even if you lay it all loose with no nails and no screw, the tape and mud will hold it. It will rattle but it will not fall. If you never touch it, you'll never know it's floating. Bob's next test date: 12/10/07

Drywall being considered structural used to exist in the US. Then the Oak Ridge earthquake in 89' changed that flawed concept real quick.

And more screws are not going to make any difference.

So drywall being structural was actually considered at one time, eh... that makes more sense now. It takes Japan a long time to actually change or amend their building codes, but when the amendments take place, they go totally overboard and go the other way.

I don't know how prevalent this is, but in our jurisdiction here (we're in north-west Washington) drywall can be used as shear panel. In the house I am building there are two walls that have drywall with a specific fastener schedule and they are on the shear wall schedule. I know from my drywaller that this is done on plenty of jobs. With the earthquakes that Japan gets I am not surprised that your jobs have shear requirements for the drywall.

Tatekata,

I'm sure your building codes are much tougher than in the states due to the earthquakes you have. Close to that of California which has dramatically increased strapping requirements etc.. of late..

I do take exception to the idea that a stick framed house is inherantly superior to a post and beam (we call them timberframed) 500 to 1000 year old homes are still lived in in various parts of the world and they are all timberframed. Few stick framed houses exceed 100 years of life and if so require massive overhauls to do so..

You mean kind of like..."I live in a 300 year old house". The entire roof, structure and all, has been replaced 3 times.The entire foundation has been demolished and replaced 5 times.All of the walls, windows and doors have been replaced, a bit at a time, at least twice over...But I live in a 300 year old house.;o)(Like 'great-great grandpa's axe'. Handle has been replaced three times, and the head has been replaced twice. But it's great-great grandpa's axe, nonetheless. LOL)

Politics: the blind insulting the blind.

Click here for access to the Woodshed Tavern

that is also known as the ship of theseus paradox.

i thinks it's in the wikipedia entry that that guy from the show american hot rod got busted by the gov'ment for rebuilding the entire car, but still claiming it was antique.

WHAT!

I hope that your statements were said in just.

Russell

"Welcome to my world"

Huntdoctor,

I am dead serious about the strength and durability of timberframing.. If I felt stick building was the way to build I would have built a stick framed house.

If you look in Europe you will find many timberframed homes that suffered severe damage during the wars and they remain in place providing shelter hundreds of years after they were constructed..

There are many timberframed homes 500 years old, even a few 1000 years old. However the average age of a stick built house in America is something like 58 years old. If you do a survey of tmberframed homes you will find in spite of the recent popularity they are hundred or more years old..

Actually, the oldest existing timberframe building in the world is the stave Church in Borgund, Norway. No one lives in it. It's a historic monument and has been refurbished numerous times. It was built in the middle of the 12th century, which makes it about 750 years old plus or minus.Most of the early European "timberframes" were "cruck" houses with thatched roofs and required a lot of maintenance and rodent control.The type of timberframing you and I and others practice evolved, in large part, in the last 400 years.

Notchman,

I was thinking about the timberframes of Egypt and Rome that remain.. Althought to be fair, I'm not sure The one in Egypt is still original.

Frenchy:

I agree with you about the old timber framed homes, they were built well and there are so many still standing after hundreds of years. Japan, of course, has temples that have withstood earthquakes, wars, etc. and are still standing.

That being said, a few years ago when I lived in Fukuoka (Western Japan), we had a 6.8 mag quake and I saw first hand the big differences in modern Japanese P&B and the 2x4 homes. Thousands of homes lost lots of tiles from their roofs, lots of homes tilted (leaving them looking like the leaning tower of Pisa), the quake really showed how the Japanese P&B houses were top heavy and had little shear strength.

2x4 homes survived with a lot less damage....

SS

Takekata,

I understand your arguement. Here in the west we use SIP's panels on the outside of our timberframes.. the intention is to provide a solid continous insulation but a side benefit is a tremendous gain in strength. SIP's by them selves are 200% stronger than the equvilant Stick built home. When you add that strength together with the strength of timbers the numbers become positively massive..

I've spent time in Japan and am aware of the tempurature swings. Which is why I don't understand the Japanese lack of interest in SIP's given their love of advanced technology..

The owner of the company I do subcontracting for right now has a house made with SIP's from Toronto. It went well, but after that subsequent panels came over and bent, warped, etc. due to the heat and humidity in the container. Also had mold problems. So they aren't very popular here right now. Cost is a big issue too, Japanese just don't have the cash to spend on their houses like they used to. Its getting depressing these days, seeing more and more products from China instead of North America.

The company I get my 2x4 materials and panels from here can make SIP panels, but they are pretty costly...nobody goes for them. The panels they make are a lot thinner than SIP's in North America.

SS

takekata,

What about ICF's? I would think that with the risk of earthquakes there it would be a natural..

For foundations here they pour a whole pad, then do 18" high walls on the pad, no basements here, so no real need for insulated forms. I use 4x4 mudsills on the foundation walls. The foundations are really nice here, the guys who do them are quite accurate and do really good, clean work. They do a self leveling compound on the last day, so when I sit the mudsills on, everything is straight and level.

SS

Takekata,

ICF's are used for walls now days. Since they have rebar through the walls you'd be pretty imune from earthquake damage, Capable off withstanding 200 MPH wind speed for the Typhons that occasionall strike Japan.. 4 hour fire ratings, Great insulational values and relatively low cost (assuming the forms are affordable) For example 9"forms cover 5.33 sq.ft. and it takes 15.1 forms to use 1 yard of concrete.. or 80+ sq.ft of wall per yard of concrete..

Actually, Mitsui Home is a huge producer of SIPS; however,

because of fears about bugs, most of them go in the roof.There is only one other mass-market maker in Japan that

uses SIPS, Taisei, with their Kukan-Oh house. This is a

very good product at a good price point, but it does not

sell well.I made a heroic effort to try and use SIPs on my own house

project in Japan, but in the end it was just going to be

too difficult to swing given regulatory and lender

requirements.As for SIPs over timberframes, that is also available

in Japan, but it costs more than the FG infill panel option,

and most homeowners are not concerned about insulation

anyway.

yes... we had some shear issues a couple years ago on one design... the PE gave us a different screw schedule to turn the 1/2" gypsum into a shear panel

somebody told me sheetrock was structural. I have thought about it and i must be missing something.

Most all rockers here like to use glue and very few nails or screws..

I think theres some strange part of the brain people use that says the more nails the better no matter what, when, or why..

The less hands on experience equals the more nails one uses.

Being as the world is running out of old men walking around a jobsite picking up nails and exclaiming... These new carpenters waste a lot of nails.... Karma dictates a new brave younger generation of nail fanatics must be born.

While old men could draw upon the phrase... Back when i was young, The new generation can draw on...When i was in school..

No logic can be used in these situations, your only defense is distraction as in.... Hey come over here and look at this new cordless drill.

21st century stuctural drywall; we use a lot of this lately, here in California.

http://www.sureboard.com/Default.asp

Edit: I was once forced to nail (sheetrock) a whole wall off 2" on center for an inspector in Santa Cruz back in '79. Taper loved it.

Mike

Trust in God, but row away from the rocks.

Edited 5/24/2008 5:07 pm by ruffmike

i wuz born in santa cruz in '44.... left in '45.... never been backMike Smith Rhode Island : Design / Build / Repair / Restore

I knew there was something special about you. ; ^ )

View Image Mike

Trust in God, but row away from the rocks.

what are the chances that the western methods are being oppressed into a level of unfeasability to preserve the home teams way...

Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming

WOW!!! What a Ride!

Forget the primal scream, just ROAR!!!

100% correct! That's how they do it here in Japan.... first they allow imported building materials in, for a certain period of time, until a Japanese manufacturer can make the same product, then the imported product all of a sudden needs to get fire testing, formaldehyde testing, etc. and is not allowed in the country anymore. After that the Japanese product goes up in price due to the lack of competetition and houses get more expensive and less unique (since all builders are using the same material).

SS

saw that procededure in the early 70's when I was there.....

Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming<!----><!----><!---->

WOW!!! What a Ride!Forget the primal scream, just ROAR!!!

So, I guess the conclusion is that drywall is considered structural (shear) in the US in some areas/applications, and there is a little sense in using so many screws.

I've done it for enough years now that I think it as normal. The wallpaper guys here do the putty/mudding work (just to get a fairly flat surface, not paintable), and they expect the amount of screws that are in the drywall, so its no big deal.

In North America it would definitely lead to a lot more work for the mudders and tapers though...

SS

If you want a real laff, look at the NBCC next time you're back in Canada.

Structural sheer wall may be sheathed with black joe on the outside and gyprock on the inside.

Yah. I don't think so, Gertrude....

Dinosaur

How now, Mighty Sauron, that thou art not broughtlow by this? For thine evil pales before that whichfoolish men call Justice....

That is actually right on the mark!

I've had to undergo drywall nailing inspections both in California and Colorado. Both had to have the 6" field screwed. The 4" edge, however was the same 6".

there are two reasons why the japanese are requiring increased structural integrity:

#1 earthquake

#2 godzilla

toolman65

Rodan takes godzilla any time any place

that depends, was the house framed in technocolor or black and white?

I’m gonna address the OP here. Tatekata, I am assuming that you do

not spend all your free time reading construction industry documents

in Japanese language like I do.

As for the sheetrock nailing schedule and shear allowables

(kabebairitsu), this is nothing new. I have a 10 year old book on

my shelf here that spells it out. What is new is the *degree of

enforcement*.

US readers might be surprised to hear that Japanese houses are only

required to get 3 inspections, and people usually get away with

skipping the final, as no Certificate of Occupancy is required for

move-in. Up to last year these three inspections were five minute

affairs, but with the post-2007 enforcement regime inspectors are

actually checking that nailing schedules are followed, etc. Much of

the inspection regime however, relies on certified filings by the

architect of record, rather than actual official eyeballs on the build.

Since there is no structural engineer on a typical Japanese house,

the architect has to take responsibility for structural integrity. Until

2007, this responsibility was taken lightly, but enforcement is now

stringent and architects have been sent to jail on lengthy

sentences for structural engineering irregularities.

That is why your architect is on your case. He could go to jail.