I need to cut rafter jacks. I have to Dewalt slider but as we know it only goes to 45. I was thinking of tinkering with a shim to get me there but I know that it’s not going to work that smoothly. Any thoughts on how to speed this up? I called a rental place but they have no tool to do this. It’s hot today and I want to finish the rafters fast……. Help! The Harv

Edited 7/30/2002 8:13:30 AM ET by theharv

Replies

lay out your 55 degree mark and break out the worm or circular saw. use a framing or speed square to lay it out. Its simple and you dont need a mitre saw to cut that wood

Instead of cutting at 55*, can't you flip the work and cut at 35* from the other side?

Are you talking about CUTTING a 55 degree angle (Like a 17/12 pitch) or BEVELLING a jack rafter at 55 degrees?

Committee - a group that keeps minutes and wastes hours.

My assumption based on your term rafter jacks, is you are cutting hip of valley jacks for a bastard hip or something similar.

A couple of suggestions come to mind. With practice you can use your finger under the table to shim up the appropriate side, I'm not sure if this works on a sidewinder, we don't use them. It might also require a 8-1/4 saw for this angle in 2x lumber.

You can also cut a straight 90 and use that as a guide by placing the tabel on this cut and following the appropriate side. Set your saw to 40 degrees.

You can by a jig for skil 77's that allows you to cut steeper angles but I'm not sure where.

You could cut a 45 and scarf the remainder out with the saw set at a 90 too.

You could go amish and use a chainsaw.

Tom

or you can use hangars and forget the 8 or 10 degrees.

clampman

theharv,

Bet I could cut one of those in less than a minute with a handsaw.

I must be old.

KK

A man after my own heart!

So many times these young bucks spend hours trying to figure out how to do it and we've already got it done by the time they've re-invented the wheel.Excellence is its own reward!

To Piffin and KKearney

Careful boys or you will date yourselves. but yes sometimes tried and true is best and faster.

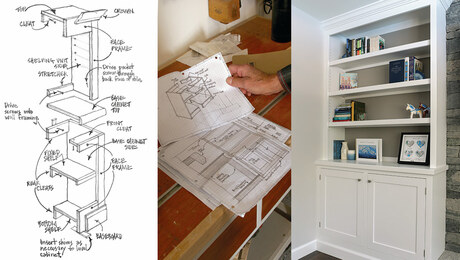

Here is what I did. I measured what it would take to shim up the rafter jack to give me the angle to bevel the miter cut. Then I planed a piece of 2x to the correct thickness. Then I mitered it carefully twice. I taped it down to the slider to give me mass production of the beveled angle. As noted I was going to use a handsaw if this was going to take to much work. But due to my age of 27. I am not use to working! My arm might have fell off. Plus I had 26 to put up all by me self and wanted to have time to play some basketball. The Harv

harv- thanks for the good har har laugh.Half of good living is staying out of bad situations.