*

We have salvaged 120 year old pine boards from a house we are renovating and have had them milled and “t&g” for flooring. We now have a collection (about 700 s. ft) of widths (12, 10, 8, 6 and 4) and random length’s from 4′ to 16′ and 7/8″ thick. We are planning to lay it out perpendicular on the existing single layer 4″ wide and 1″ thick flooring. The room is an “LL shaped second floor family room. (The entire house is gutted).

Any suggesting on how to start this jigsaw puzzle?

Also, the mill recommended to both glue and nail in the floor.

Any recommendations will be really appreciated….

Paul

Replies

*

How do you plan on finishing the floor? We are doing something similar to this. New shiplap pine floor. We are going to use black iron nails and construction adhesive. The homeowner is going to put a clear oil based poly on the floor. Should look very nice when it is done. You could also screw and pug the boards but this would take a long time.

*I was going to go with ship lap, but for an unarticulated reason my wife preferred the "t&g".Finishing is another matter as well. Poly seems to be the standard way to go in this area (Ottawa, Canada) but I've read a lot of good things about oils and waxes. Still lot's of research left to do.I've also been thinking about using screws and plugs. Any idea about distances between the screws?Do you know how you are doing your layout?Paul

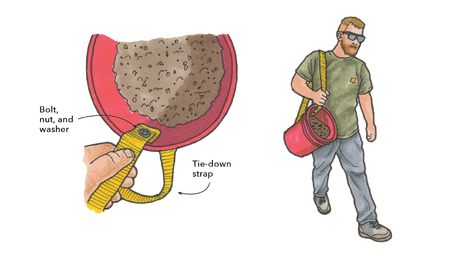

*You can install the room either direction, generally with the longest wall, but whatever appeals to you the best is the way to go. You are the one that lives there. Softwoods are now being full spread glued and nailed on the tongue and a center face nail every 14" on center for boards over 8" wide. Urethane glues are the best for flexibility later. Glues keep the floor quiet and retard cupping and crowning. These glues dry very fast, so only spread a couple of rows at a time, and wash any excess off the face after those rows are installed. You'll have to scrape it off later. Don't install boards that already have a cup or crown. They will give you trouble later. GW

*To make sure you get an even mix of widths, i.e. you don't end up with all 8" boards in half the room, you might want to make separate piles for each width. Figure out the square footage in each pile, and use these numbers as a proportion for how often you grab from that pile. If you have twice as much 8", go to that pile twice as much, etc. Refigure the proportions when you're half done to make sure you're on track. Don't use a repetetive pattern either, try to make the rhythm truly random....Mike

*Lucky you went with T&G. Just did a shiplap pine floor which was a dirt pump because the installer did not button down the edges enough, lot of movement.Need to glue because of the wide widths, might squeak otherwise. Polyu. glue was a good idea. Might rent a compressor and pneumatic stapler like a Bostitch for the job, staple every 8-9 inches. Don't worry about shooting over joists, staples fire in on angle, so only 1/4" or less goes into joist, not enough to hold.Worry about your pattern. Try to stagger seams from one course to another about a foot for wide stock. This drops to about 8" for regular strip flooring. Makes a better pattern, less movement, less squeaks.Suggestion to know what you've got for inventory is crucial, so you can plan what you use for courses.Whatever is most plentiful has to be worked in, the scarce stuff has to be used in planned, spaced courses. If goods are end matched (T&G), don't be afraid to cut a board to start a course, plan on using the other half as a starter in appropriate place.Using decorative face nails like iron or copper looks good initially, but later becomes a dirt spot as the nail protects the area just around it from wear or cleaning contact. Later refinishing also is impossible. Good oil poly coat is nice, three coats, use a good quality stock likeMinwax or Zipguard. Don't use sanding sealers, they are softer to allow easy sanding of raised grain after first coat, but are not a durable wear coat.

*007:I was planning of screwing down the original pine floor into the joists before laying down the new floor. Is this not a good idea?Paul

*

We have salvaged 120 year old pine boards from a house we are renovating and have had them milled and "t&g" for flooring. We now have a collection (about 700 s. ft) of widths (12, 10, 8, 6 and 4) and random length's from 4' to 16' and 7/8" thick. We are planning to lay it out perpendicular on the existing single layer 4" wide and 1" thick flooring. The room is an "LL shaped second floor family room. (The entire house is gutted).

Any suggesting on how to start this jigsaw puzzle?

Also, the mill recommended to both glue and nail in the floor.

Any recommendations will be really appreciated....

Paul