*

Andrew,

Is a 16d common nail thicker in diameter than a galvanized joist hanger nail, 1 3/8″?

MD

*

Andrew,

Is a 16d common nail thicker in diameter than a galvanized joist hanger nail, 1 3/8″?

MD

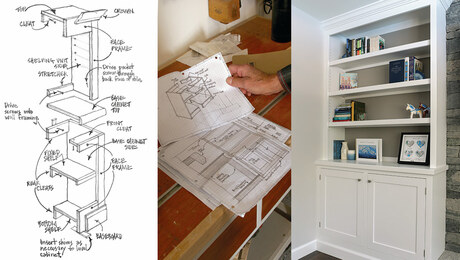

A standardized approach, quick-to-install hardware, and a simplified design make building custom casework cost-effective.

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Get home building tips, offers, and expert advice in your inbox

Fine Homebuilding

Get home building tips, offers, and expert advice in your inbox

© 2024 Active Interest Media. All rights reserved.

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Get home building tips, offers, and expert advice in your inbox

Become a member and get instant access to thousands of videos, how-tos, tool reviews, and design features.

Start Your Free TrialGet complete site access to expert advice, how-to videos, Code Check, and more, plus the print magazine.

Already a member? Log in

Replies

*

Thanks for the info, Andrew. I thought you had posted the diameter importance thing, but I see it was actually Ron. Anyway, I gotta go look at the things, (joist hanger nails) they sure seem a whole lot thicker than 10d.

*

Andrew: I prefer Kant-Sag, but what really matters is what I can get fast. One nice thing about Simpson is that their universal framing anchors (A35) carry a specified capacity listed in the catalog, where the architect/inspector can refer to it. Kant-sag doesn't give a capacity for their angle.

Oh, by the way, the Simpson cross-nail hangers actually say 16d SINKER right on them for the toenails.

*... sinker means thinner shank, like 10d? probably a splitting concern, thanks, I probably wouldn't have noticed now that I bought a batch of Simpson hangers at 50% off. But does anyone read instructions? :)Boy, I bet you'll be excited to know that USP publishes comparison guides showing the strength of their connectors relative to Simpson "equivalents." See below -- I didn't figure out what the direction codes mean; the guides can be found at http://www.USPconnectors.com/ -- it looks like the two are roughly at par in general, maybe an edge to USP.

*

I thought joist hangers are attached with joist hanger nails? I know if the inspector in my area sees anything other than joist hanger nails in the holes, and every hole,they aren't gonna fly.Joist hanger nails come in longer lengths,for double shearing the member being attached. Does anyone have a thought on this?

*Most joist hangers require 16D common nails to develop their highest rated capacity. And, yes, all the holes are supposed to be filled. But check with whomever sold you the hangers - they should be able to supply you with the actual requirements of the hangers in your situation.

*1 3/8" joist hanger nails should be used only when nailing into a single 2-by. I believe when nailing into a single 2-by joist hangers are only rated for about 70% of their capacity. Use 16d common (or longer joist hanger) nails for all other applications.

*Tell your inepctor you just do what the mfr tells you to d -- that what the code requires, right? FH was right on as I recall -- 16d common means 16d common. Go to the source -- both Simpson and Kant-Sag have detailed info on their Web sites that you could print out (Simpson even has a free CD-ROM for those who like REALLY boring reading):http://www.strongtie.comhttp://www.USPconnectors.com/

*Addendum -- USP (does anyone else prefer these over simpson too?) does produce its own full line of nails, while also publishing tables covering essentially all nails. Note that for the really particular, the precise rating depends on the wood species, too. See attached, from their site.

*We always use the Simpson brand joist hanger nails. (This is where the palm nailer earns it's keep) I always was under the impression that it was the shear strenght of the nail that was important here. Not how long the nail is. All the weight of the hanger is shearing down on end of the nail anyway. I don't see what difference the extra length of a 16d would do to help. With all the weight pressing down on the end of the nail, the extra length of a 16d seems kind of moot.When we frame, we use 12d vinyl coated hand drives. I haven't bought any 16's for years and years. We shoot 10d paslode brights when we frame. They seem to work fine.Ed. Williams

*The load reduction of 23% is real though -- pullout strength is the diff. Of course, I wonder how many people actually engineer hanger-supported assemblies? Even at 77% I assume they are much stronger than toenailing. The shorts are inadequate for attaching to beams, I'm sure, and couldn't be used for the double-shear nailing some Simpson hangers provide -- the only reason the joist hanger nails exist is to provide a thick nail that won't punch through a 2x. Again, though, even at reduced strength I wonder how much it actually matters?

*Ed - It's not the b lengthof the nail that's important, but the b diameter. They call it "dowel bearing strength.", I think. The more wood the nail has to rest on, the more capacity the nail has. Pullout strength isn't a factor.

*"It's not size that matters..."Simpson defines (table I loaded above) minimum embedment by a certain multiple of the wire diameter. I'm not claiming to know anything special about these hangers, but would like to know the answer. I doubt shear strength is the critical number -- instead, I picture the nails losing their grip on compressed wood fibers. I recall somewhere seeing a recommendation for using clinched nails -- nails pounded all the way through a member and then bent over -- for some particular application.

*Andrew, when you use hangers with TJI's you often need to beef up the tji with web stiffeners on each side. Simpson says to use clinched nails for the web stiffeners. That may be the application you may be recalling?jim

*Andrew, Is a 16d common nail thicker in diameter than a galvanized joist hanger nail, 1 3/8"?MD

*The USP "joist hanger nails" are supposedly 10d. I'd say they look about that diameter.About the fill every hole rule. It depends on the hanger. Simpson has holes of different shape. Nails must go in the round ones, are optional in the diamond shaped ones and the shear ratings of the hanger are given with and without the shearnails.I may have some of that mixed up, I don't use Simpson.

*Jim, I know about the clinching for TJI's; perhaps that was what I was thinking of.Ryan, you're basically right -- see the Simpson clip I posted above, nails.gif.Mad Dog, the hanger nails I've seen are always stamped with the gauge on the head -- 8d or 10d. Confusingly, it may be that 10d doesn't always mean the same thing ... what does Simpson mean by "steel thickness gauge"? A 16d is definitely stronger than an 8d or 10d hanger nail.