<!—-><!—-> <!—->

I have just finished a framing up a friend’s basement. Five months of weekends. Close to 150 hours. That includes framing, insulation, wiring and other odds and ends. We hired another contractor to do the drywall and finish it up because a deadline was fast approaching.

<!—-> <!—->

I did 2×4 wood studs for walls and used combination of 2×2’s and 2×4’s for boxing in the duct work and plumbing.

<!—-> <!—->

I am wondering how I could save time for the next one.

<!—-> <!—->

One contractor told me he uses wood for the walls but metal for boxing in any ductwork.

That ductwork took me a long, long time.

<!—-> <!—->

Another thing I would never do is not use Tapcons to fasten down the sole plates. Man what a pain. The aggregate must have been diamond because I went through drill bits like they were candy.

<!—-> <!—->

I am still debating whether or not it is best to fasten the top and sole plate first and add studs or build the walls first and raise them.

Also I used screws. Not again. I would buy a nail gun and shoot it together before I did that again..

Replies

Where is blue eyed devil when you need him?

believing you have been hanging here since 2001 and wrote this? be a joker:o)

Edited 6/23/2005 6:14 pm ET by razzman

C'mon man - read the rest of his profile. He's 'clerical/administrator'. Give him a break, eh....he's been busy doin' the paperwork for 4 years first!cheers

***I'm a contractor - but I'm trying to go straight!***

You should have come here before you started not after you finished. Next time rent a hammer drill and use a decent drill bit, I drilled over 3500 holes with a single hilti 5/8 bit through grouted block. Grout had a 5000 psi rating for those who care and the bit still cuts good. Or rent a powder actuated fastening system and shoot the plates down. I always build the walls on the floor, unless there is such a discrepancy in the floor to ceiling measurement that it make this not feasible. Measure floor to ceiling and find the smallest distance, then measure diagonally along the length of a stud and mark it. Then measure straight down the edge of the stud and this will show you the length of the wall plate to plate that will fit comfortably. Subtract a quarter from that because you may have discrepancy in your cuts and you should be good to go. Don't forget to subtract the width of your plates from this measurement. Remember to shim between your top plate and the joist to which you are fastening. As a non professional you might want to consider metal for everything, walls and bulkhead. We use 1 5/8'' metal for our bulkheads. Level along the wall and snap a line. Level out at each end, and run a strings along the front edge and underneath 1/2 an inch proud and use 1/2 '' gauge block to build. Don't forget treated 2X4 against concrete and galvanized fasteners. I almost forgot - crown your studs.

Edited 6/23/2005 7:12 pm ET by quicksilver

Edited 6/23/2005 7:15 pm ET by quicksilver

Edited 6/23/2005 7:40 pm ET by quicksilver

"You should have come here before you started not after you finished."

I actually started several threads over the last few months regarding the issues I had. Couldn't have done the job without the kind folks on this forum.

Metal studs and framing.

I Love A Hand That Meets My Own,

With A Hold That Causes Some Sensation.

[email protected]

Been in the same instance many a time and I now knock out an average basement in a weekend. First lay and snap out the whole thing a few days prior. Make sure you have all of the RO's for doors and windows Shoot the plat to the floor with a PAT (put on ear muffs and make sure the kids are outside), even the hammer actuated ones will work, and construction adhesive. With a good straight edge and level (6' if you have one) plumb up and shoot (that's right buy or rent a nail gun) the top plate into place. Now measure the heights between the plates, find the smallest in any one run and cut a stud to that length. At each layout spot, pry and shim the toplate down to fit the story stud. Once done, cut two more studs plus two plates at 11 5/8", nail them into a box with the shorts inside the longs. Starting left to right shoot in the first "l" studs as plumb as possible. Slap in your story box, then the next stud, shoot it in. Work your way down the wall and in no time it will be common studded out. Add in any "u"'s for partition wall perp to this. Windows and doors will require alterations of course but you can knock out the common walls before lunch this way.

When it comes to ducts, soil stacks and lolly columns I build as much as I can on the floor and beat it into place with my trusty 28 oz Estwing. If I have to box out ducts on three sides in the ceiling I put in the studs all on the flat. I'll nail blocking between the joists along a line. Then picking a length a little more than I need I shoot on hanging studs at each joist, plumbing as I go. Then I snap a level line across and shoot on the horizontal hanging joists, flush on one end and longer on the other. I'll shoot up every four or five, fish in a strongback stud through and then fill in. Then it's time to break out the sawzall and trim the stud ends.

That usually takes me to dinner so then it's time to get into overtime. This usually involves the wall beneath the stairwell as the HO will want storage there and often the furnace or what not is there and you need access and ventilation for them. My simplist solution is installing louvred bifolds in pairs. Framing these out will take me to beer'o'clock. Sunday then is spent tweaking out of plumb studs, drywall blocking (if in doubt add it), any blocking for trim I might want, anything I might have skipped, etc.

Bear in mind I do this with at least one helper. If I'm doing this on a weekend anymore it's for friend or family so that means sweat equity! I'll usually recruit the guy whose basement I did last month to help with this month's. Most people are so happy to have the framing done so quickly that they're happy to comply with my "contract". If you're doing this for cash, hiring at least one good helper will, well, help.

Screws work nice but they're slow. I use them in spots I can't get a nail gun or swing a hammer and then I'm using a right-angle screw gun. I've never had good luck with tap-cons in well cured concrete, they're great in green or fresh, although the Bosch Bulldog hammer drill will often do the trick. I also treat every wall with headers if I can to help prevent cracking the rock.

I picked up a tip from FHB a couple of years ago - lay your sole plate, plumb up from that to the ceiling, where you fix a METAL top plate. Then you can cut studs to up to 1/4" shy, even, and screw them in. Works dandy.cheers

***I'm a contractor - but I'm trying to go straight!***

I like the simplicity and the slop allowed with this system I but I ask this. If the drop ceiling is below the tops of the sheetrock, then screws aren't an issue. However if the ceiling ends up being a modernist rock to rock joint, then the screwheads are sure to monkey with the plane of the wall intersecting the plane of the ceiling, assuming the omission of crown molding. If these aren't concerns, then using a PT sole with a metal top track sounds quicker...do 2x wood studs fit into the track? Will the studs be firm enough since toenailing into wood isn't an option and all that you're left with is a screw in one face? Being able to toenail into at least three faces of the stud allows me to cross-pin the structural member locking it into place.

we always use metal tracks screwed to the ceiling and wooden studs screwed into place. the issue with the screw sticking out interfering with the drywall is a non issue. it would be the same with metal studs in metal tracks and that's the way they are designed to work. we just famed up a basement in about a week with a huge amount of bulkheads.

Custom Cabinetry and Furniture<!----><!---->

http://www.BartlettWoodworking.com<!---->

I 've realised that there will be additional strength if one installed a lumber top plate first, before a metal 2nd top plate. And indeed a metal sole plate would be an advantage too, becouse one doesn't have to toe-nail (not everyone's good at that, especially with hand tools).

Yes lumber studs do indeed fit. There will be 2 screws top and bottom - ask yourself Q - how many nails go into studs? A - 4.

If you're really worried about finishing off at the ceiling use paper L-bead up there (or a metal J-bead) and mud in a nice crisp line (covers the d/w screws too). Or use a plastic J-bead that is more forgiving and you can push it up tight where the ceiling plane varies.cheers

***I'm a contractor - but I'm trying to go straight!***

So if you use a metal channel and wood studs then you only need one screw at the top and bottom to hold in the stud?

Well, one per side, per top, per bottom, actually. It's the industry standard. All those open plan office buildings - there's 4 screws per stud holding up the partition walls. And we're talkimng non load-bearing here - a partition wall for you in a basement reno would normally be that. It'll only be holding the D/W up, and a few pictures (I presume, tho, you'll keep the Renoirs upstairs rather than the rec room....)cheers

***I'm a contractor - but I'm trying to go straight!***

I remember reading the same FHB article. Great idea.

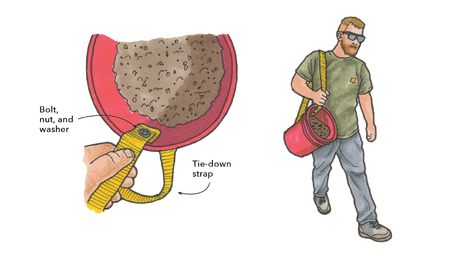

first of all use a Hilti gun for the floor plates, and use 1/2 ply for the bottoms of the duct work framing (saves headroom)

framing for a finish basement is always time consuming, you should also consider steel studding for the walls

caulking is not a piece of trim

Would you then skim coat the ply? That would save quite a bit of headroom. How about boxing them in with ply shot or screwed to nailers? Would be lighter and you could put the box together, hold it up and fasten...

no, i'd fasten the drywall to the ply, get a better finishcaulking is not a piece of trim

Asennad, I just got out of a basement rough-in this week. Since I'm a "minimalist", I tend to try to eliminate all wasted wood. I'm also the kind of guy that thinks things through and I use the easiest systems known to man.

I worked with a one year apprentice and together we roughed in a 1500 sf basement in two days. My day consisted of starting late and leaving early....about 12 hours total. His day was slightly longer the first day. I'm thinking we had a total of 25 hours total. The work day pace was very easy with long coffee breaks and a long lunch.

The basement was 9' deep but since the 10" steel beam and duct work dropped down, the clients decided that they'd like a nice flat level 8' ceiling with no ups and downs. Most guys would order 9' studs. Not us. We ordered precut 92 5/8" studs. We only used one top plate. We put the studs on 24" centers. We nailed the bottom plates to the floor with good old fashioned cut nails. We had a Hilti ten shot power acuated fastener tool there, but I find them to be too slow. I can hand drive the Hilti shots faster.

We had to frame out for one egress window and one glass block window. We installed two pocket door frames. We put in a family area, three bedrooms, each with a closet, a 3/4 bath and a kitchen and a couple of storage/workroom areas.

I had about an hour of "boogerin' " at the stairs, otherwise everything was just like building new.

We firestopped the entire perimeter at the top, according to code (the inspector doesn't want a fire to draft air out of the ceiling plenum).

Our framing "system" works fine and it's very easy. We frame the walls in 14' sections on the ground. We tilt them up and use short diagonal braces to the ceiling. At the outside walls, we leave about 1" air space so we don't have to fight the uneven concrete walls. That gap is closed at the top with a second top "plate" (we use a 1x4 and push it tight to the concrete). Any small gaps that still remain are stuffed with firestop insulation specifically designed to stop drafts.

The builder will drywall our walls and install a suspended ceiling.

We didn't have any drops or wiring...we rough framed everything.

I was able to drive up to the egress window and unload the materials, so material staging was minimal (about 1-2 hours total).

All in all, it was a pleasant diversion for a few days and since it was hot, we welcomed the cool basement work.

I have done basement drops a hundred different ways. One way that I particularly like involves the use of an aluminum brake and white coil stock. I bend the drops in a "z" shape and screw the top flange to the joist. The white dropped sidewall works very good with white ceiling grid and the entire assembly looks great when done. The grid screws easily to the metal and matches perfectly. The only drawback is seams, but those are fairly inconspicuous. The seams should be discussed with the homeowner first, but I've never had one reject the idea. They like the thought that they will never have to paint the drop.

Please don't chirp too loudly about not running the plates up to the ceiling. I've learned my techniques when framing a commercial office in a 20' tall commercial building. The studs didn't go all the way to the ceiling in that building, so they don't need to go all the way up in a 9' basement! 24" framing might be too "flimsy" for you too, but I know from experience that once you put all the board and ceiling in, you'll never know the difference unless you intend to use the walls as a kickball backboard!.

Save the owls, it's a basement for cripe's sake!

blue