waterfall island/table design questions

Hi all,

I am new to the forum. For about four years I’ve been doing a lot of remodelling from framing, to plumbing, electrical and building some simple furniture. Jack of many trades, master of none.

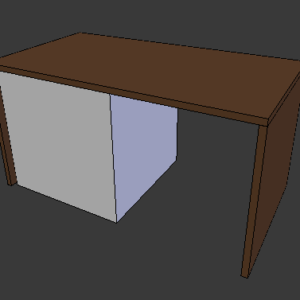

My next projects is to build something like in the attached image: an waterfall island/table. I have two 1.5”x73”x39” oak butcherblocks (of which one will be cut in half) On one side, there will be two back-to-back cabinets (for a total of 36”x36” fooprint) and the other side will be used as a table, with higher bar stools.

My main concern: will the butcherblock sag over time for that 36”x39” unsupported span where the stools will be?

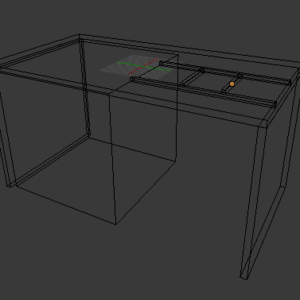

do I need an angle steel frame to support that? maybe two 1”x1”x1/8” angle metal 12” from the edge along with long side of the island and 3 or 4 that run perpendicular on that (to create a torsion box)? (see 2nd image)

Also, I don’t want to miter the two slab edges. What are my choices for connecting the vertical and horizontal butcherblock pieces on the table side in a sturdy manner? Dowels? Epoxy? Another angle metal piece with pre-drilled holes for countersinking the screws? (Don’t really like the look of dovetails) The angle metal can be painted black and would be ok since it’s not really visible.

The floors are sealed concrete. What are some options for connecting the wood slab to the floor? Metal dowels?

Thanks a lot and looking forward to learn.

Kenzaburo

Replies

There will be no discernable sagging with the oak slab over a 3' span, unless you plan to use it for a workbench to overhaul V8 engines.

If the cabinet will serve as a brace to prevent racking of the inverted U-shape, the joint between the top and the end walls can be made with simple dowels or biscuits. This is because you also plan to anchor the sides to the floor. The only time joint strength would be a concern is during handling/moving of the unit. Steel angles screwed to the inside corner could be positioned back from the edges so as to be unnoticable, if you feel the need for more strength.

Steel dowels or anchor bolts into the concrete will do nicely. A bead of caulking along the joint between floor and sidewall will keep the unit from lifting, although it's hard to imagine what might cause lifting.

Presuming that the butcherblock is laminated with face or edge grain running between the supports, it won't sag. If the grain runs the other way or if the butcherblock is end grain, it would need support.